Metal plaster mesh: features of use

The use of reinforcing mesh during plastering has recently become mandatory, and most often a metal mesh is used for this purpose, which will be discussed in this article. The metal plaster mesh must have the corresponding certificate without fail, otherwise the work performed will not comply with GOST, and if we talk about the construction or decoration of public facilities, this requirement must be fulfilled.

The content of the article

Types of Grids

In fact, a metal mesh for plastering is a concept that gives almost no idea about this material. Today you can find a huge variety of metal grids, many of which have additional protection against moisture and active alkalis, which are very much found in cement and mixtures based on it.

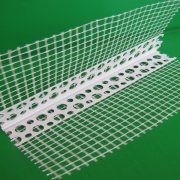

Insulated metal mesh for plaster, can also be of several types, and differ in insulating material by:

- Plastic.

- Galvanizing.

Of course, the price of such a mesh is slightly higher than that of a simple metal one, but it does not corrode and, accordingly, rusty stains will not appear on the wall in a few years.

Important! In no case can a galvanized grid be cut with a grinder, since together with the cut, the protective coating will completely burn out, and it is from here that corrosion will subsequently begin.

So:

- The metal mesh for plaster, covered with plastic, is not inferior in quality to galvanized. But only if we are not talking about cement mixtures, which are alkaline, and just corrode plastic over time.

- Of course, modern technologies do not stand still, and today there is plastic resistant to active alkali, but even it loses its properties after a few years.

- For clarity, you can conduct a small experiment: take a piece of mesh covered with plastic protection and place it in a cement mortar for several days, then take it out and look - low-quality material will begin to peel off from the metal in a few hours, but nothing should happen with high-quality plastic, nothing will happen .

Rabitz

This mesh cannot be fully called plaster, and for many of us it is better known as material for fences or temporary fences.

In fact, this is a lot of wires woven together, but not fixed at all. This production method can be considered both a plus and a minus, since the netting can be folded into small rolls, which is convenient for transportation, but at the same time, it can be difficult to unwind.

Mesh netting, can be either just metal, or with a protective coating in the form of plastic or zinc.

Advice! Always ask the seller for a certificate for a metal plaster grid, especially if it is coated with zinc, as many negligent manufacturers often use substitutes that are worse in quality instead of expensive zinc, but you can’t tell them apart.

| pros |

|

| Minuses |

|

As you can see, the netting has a few more minuses than pluses, builders are aware of this, so many try not to work with this material, preferring simpler and more convenient competitors.

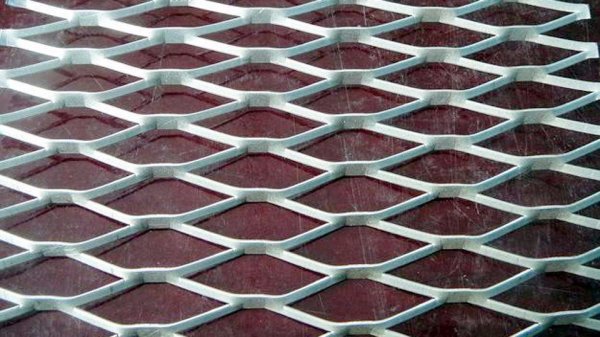

Notch

Like a chain-link, this mesh cannot be fully called plaster, since its initial purpose was different, but the builders quickly saw all the advantages of the material, and today it is a very popular material with a number of positive qualities and characteristics.

By the way, a perforated metal grid for stucco is a common name, since in fact, it is labeled with the abbreviation CPVS, which means an all-metal expanded metal grid.

The name fully shows the production process of this material. That is, at first, the guillotine makes a slot in the steel sheet, after a certain distance. After that, the machine draws a sheet, and thus cells of the same size are obtained.

Despite the apparent simplicity of production, it is unlikely that it will be possible to make a DCPC with your own hands even from a very thin sheet, since this will require perfect accuracy in the cuts and a huge force for drawing.

Minuses:

- This is the heaviest grid, since even the thinnest sheet of metal weighs several tens of kilograms, and this must be taken into account when attaching it to a wall made of hollow brick.

- Perforated mesh does not happen with plastic insulation, and after applying zinc, its cost increases several times.

- An all-metal mesh is very difficult to bend into rolls, and is most often sold in the form of sheets, which is somewhat inconvenient during transportation. If it is nevertheless curled, then the grid gets used to such a position and give it, then the initial even shape will be very difficult.

Pros:

- Very high tensile strength. Tearing a perforated mesh is almost impossible.

- The density of the mesh allows plastering of any thickness and weight to be applied to it.

- You can mount a segment in only three or four places, and the whole process happens very quickly.

- Due to its strength, perforation can be used not only for plastering walls, but also for the manufacture of concrete screed or pavement.

Welded

Today, welded metal mesh plaster, is considered to be the most popular and sought-after material among builders and customers. Here the price and quality are perfectly combined.

In addition, the welded mesh can also be zinc coated and it is very tear resistant.

Advice! When buying a net in a store, to make sure its quality, it’s enough just to selectively move a few wires, if at least one connection comes off, maybe this will happen with the whole roll, which means you should look for another manufacturer.

Minuses:

- The grid in rolls takes the form of an arc, and the thicker the wire, the more difficult it will be to give the grid an even state.

- Resistance welding, used in the manufacture of welded wire mesh, may come off.

- Welding spots are the most vulnerable to corrosion, and even zinc here can begin to rust.

- The smaller the mesh size, the thinner the wire, and the more weld points, and therefore, the more likely that the welding will begin to break and rust.

Pros:

- Light weight mesh does not create additional load on the walls.

- If necessary, plaster metal surfaces, such a mesh can simply be welded to the base.

- You can simply cut the wire with scissors for metal, and you don’t need a grinder or a jigsaw.

- Huge selection of mesh, which can be selected even for the most specific tasks. It can vary both in cell size and wire thickness, and these two factors can be any.

Conclusion

As you can see, a grid for stucco is a very broad concept, and in this article we talked only about metal. Which grid to choose, the question is individual: some cost more, but it’s easier to work with them, others are cheaper, but you will have to suffer a lot during installation (see How to fix a stucco mesh to a wall) Therefore, choosing a material for the plaster, it is worth thoroughly weighing the pros and cons described above. Well, to understand the process of plastering with a grid, the instructions shown in the video in this article will help.