How to fix a stucco mesh to a wall

Fixing the grid under the plaster must be done according to certain rules. After all, the appearance and durability of the entire plane will depend on this.

How to fasten the grid under the plaster, we today and consider in detail. Although this is not a difficult job, but it is carried out according to certain rules and they should be done. Also on the video in this article and photo are possible options for doing this work.

The content of the article

Basic rules for choosing a plaster grid

Fastening the plaster mesh to the wall is done according to certain rules. only first you need to choose it correctly. The manufacturer made sure that there was a wide fiberglass mesh selection.

If you do not want to immerse yourself in the question, you can trust an experienced master. He will select the grid, the correct fasteners to it, will help to qualitatively perform its fastening to the wall.

You can see photos of various types of grids. But the most important thing is to choose the right one to choose. How to fasten the grid under the plaster and how to choose the right now we will consider in detail.

When choosing a grid, you should pay attention to such nuances:

- The mesh should have good resistance to alkaline solutions. To do this, it must be placed in such a solution for 25 days, and then tested for breaking. Strength reduction should be minimal.

- The mesh should be tested for tensile strength.. To do this, take a small piece of the net and try to crush it into a ball, after which it should take its original shape.

- Pay attention to the quality and size of the cells.

- All main characteristics of the product are indicated in the passport. manufacturer indicating the tests performed.

Attention: Do not forget to immediately purchase fasteners, because the mesh should lie on the surface and not puff.

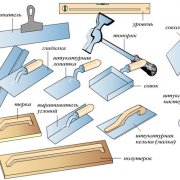

Stucco mesh

The maximum effect can be obtained only when the fastening of the grid for plaster is done correctly. Everything can be done with your own hands, then the price of the work will not be significant.

It must be firmly held on a plane, because it will have a small weight. If this effort is performed, then it will be possible to say with confidence that the plaster layer, during operation, will not fall off from the main surface and will not crack.

Despite the large number of types of this coating, the stucco mesh is fastened as tightly to the plane as possible. To do this, plastic dowels with self-tapping screws can be used, to which the grid is attached using metal, galvanized wire. In this case, the reliability of the plaster layer will depend on the reliability of fastening the metal mesh.

Metal plaster mesh

How to fix the plaster grid will be considered in more detail.

It is also represented in the construction market in a wide range:

- By type: welded, woven, netting, perforated, reinforcing, etc.

- Cell shape and sizeas well as location and structure.

- By the size and diameter of the metal wire.

- By the presence of coating (galvanization, polymer).

Attention: The assortment of metal mesh is so large that it can be used in almost all areas of repair and construction work, which cannot be done without reinforcing mesh.

Metal mesh (see Plaster grid steel - types and application) is able to maintain its original shape both during its laying and during operation. This allows you to get better plaster surfaces with longer life. All reinforcing mesh made of other materials do not have such high stability that narrows their scope.

Based on the foregoing, we can safely say that the metal mesh is more universal, and it can be used:

- Practically on all types of surfaces and with the use of any type of plaster mixes and mortars, while the plastic mesh is designed with gypsum plasters, it is not recommended to use it with all other types of mixtures.

- With various layers of plaster mortars applied to the surface. With its help, you can eliminate differences in roughness from 6 cm or more. Other types of reinforcing nets, including fiberglass, are allowed to be used with a coating thickness of not more than 3 cm.

- If a plaster mesh made of galvanized metal or with a polymer coating is used, a reliable and durable surface can be obtained. Such a grid has excellent indicators of moisture resistance, wear resistance, strength, etc.

The sequence of fastening the metal mesh:

- First you need to measure which segment of the grid you want to fix. Typically, this will be the size from the floor to the ceiling. This size is transferred to the net, after which it is cut with metal scissors (if it is a thin net) or using a grinder, if it is a netting net, with a wire thickness of 2 mm or more.

Attention: If the grid is mounted on the wall, then the top edge is fixed first. To do this, you can drill a couple of holes, insert into them on the dowel and screw in the self-tapping screw. It is possible with a wide hat. After that, the cropped piece of mesh is simply worn on the screws and pressed with the same screws. After that, it can be thoroughly fixed without any problems.

- If the grid needs to be fixed on the ceiling, then everything is much more complicated and one person can not cope with it. Mounting can be done in the same way, but first four corners of the grid are fixed, after which it can be finally fixed without assistance. But if you take in general, then you can’t do without an assistant.

- The fixing frequency depends on the size of the cells and the thickness of the mesh material. In all places of fastening, the mesh can come into contact with the main surface, and in the intervals between fastenings it should move away from the surface, otherwise the reliability of the plaster layer will be reduced.

- Before reinforcing the mesh, all debris is removed from the surface and dust is swept away. Before applying the plaster layer, the base surface should be moistened for better adhesion.

- A properly fixed mesh should be stretched like a string and not vibrate in places where there are no fasteners, otherwise during operation, under the mesh, voids can form that will negatively affect the final result.

Fiberglass plastering

Now let's talk how to fix a plaster grid of plastic.

Such a mesh is recommended in such cases:

- If there is a need to strengthen the surface layer of plaster, regardless of the type of building.

- It is used for reinforcing waterproofing layers of roofs and floor slabs.

- It is necessary to enhance the mechanical strength of self-leveling self-leveling floors.

- It can be used to strengthen plaster mortars designed to prepare the surface for laying ceramic tiles.

- It will be needed to reinforce plaster surfaces applied to materials having different coefficients of thermal expansion.

- It is very important when applying a plaster layer to the lower base of the building.

The technology for laying the reinforcing mesh is very simple and anyone can do it:

- Plaster nets with a density of 145 g per square meter and mesh with a density of 165 g per square meter are very popular among builders. These nets are mainly used for reinforcing the plaster layers of the facades of various buildings.

- The consumption of the reinforcing mesh is 1.1 m per 1 square meter of area, with a mesh width of 1 meter. Fiberglass nets are used to strengthen plaster layers in places where completely different materials are used, for example, brick and wood. It allows you to carry out high-quality work in places where slight deformation changes are possible, in the presence of plastic corners, in places where the plaster layer adjoins the insulation materials of window and door openings.

- The technology of laying fiberglass mesh requires that it be recessed into a fresh layer of plaster to a depth of about 5 mm. In this case, it will be in the middle of the applied layer of plaster, which guarantees high strength and solidity of the plaster layer.

How to fix a fiberglass mesh

Fiberglass mesh is no less popular than metal. Even building insulation with polystyrene is not without the use of fiberglass mesh.

So:

- Such a grid is mounted after the fixing of the foam plates to the base surface is completed.

- A rough coat of plaster is applied to the surface of the foam. Work is carried out in small areas, as the mixture tends to solidify quickly.

- The mesh is trimmed according to size and applied to a surface that has not yet solidified. After that, a wide spatula is taken, and the mesh is leveled and as if pressed into the freshly applied putty or plaster.

- After this, time should be given to ensure that the surface with the mesh grasps well. Usually on the second day, work continues on this surface. First of all, you need to walk along the surface with a spatula and remove all burrs or mounds.

- When installing the grid, you need to ensure that each strip is on the previous strip with an overlap of 15-20 cm, otherwise cracks may appear during operation.

- After the excess debris from the surface is removed, you can begin to apply the finish layer.

- Here is a special case of the use of fiberglass plaster mesh, but its scope is much wider.

- When carrying out repairs in private homes that have a solid lifetime, there’s nothing to do without fiberglass mesh. This applies to both walls and ceilings.

- When carrying out repairs in multi-storey buildings, and especially during puttying work on the ceiling, where significant differences occur due to unevenly laid floor slabs, it is also recommended to use a fiberglass mesh. There are times when it does not help and you have to mount drywall.

- If the walls are gypsum-block and there is a need to cover them with a layer of putty, then the plaster grid will not be superfluous.

How to fasten a stucco grid to a wall you now know. The instruction will help you to select it competently and after that to securely fix it.