Ceresit plaster

The combination of cost, properties and purpose among the finishing materials stands out Ceresit - Henkel plaster. The product is sold in the form of a dry mix or finished paste. The dry mixture is packaged in bags of multilayer kraft paper weighing 20-25 kg, and the finished plaster mortar - in plastic buckets. Manufacturers operate in Eastern Europe and in Russia. Reasonable price and species diversity, ease of use, decorative properties made the product popular. Mixtures are bought for a modest home renovation with their own hands and for the decoration of large objects with massive attendance.

Ceresite - plaster for every taste: decorative, front, draft, finishing, restoration. Depending on the brand and component composition, the material is used to eliminate chips and cracks, smooth surfaces, and decorate. With the help of Ceresite, they perform thermal insulation of building facades. Application technology - manual or mechanized, layer thickness - from 2 to 30 mm.

The content of the article

Types and brands

Decorative plaster Ceresit is available in a wide range of types. The intended purpose of the brand determines the component composition and type of astringent ingredient. On sale there are:

- Acrylic mixture "Bark beetle". Plaster for facades and interior interiors of a dispersion structure with decorative inclusions (marble, granite or quartz chips, small fractions of natural stone, volcanic glass, grains of mica). Creates a raised surface or forms a smooth finish.

- Dry cement putty. Universal mixture for indoor and outdoor use. It is used in decorative design and leveling of surfaces, has a mineral base, and is characterized by active adhesion with different surfaces.

- Silicone putty. Designed for the treatment of wooden, cement and gypsum surfaces. Forms a vapor-permeable coating, protects the base from exposure to harmful microorganisms.

- Silicate paste. It is used for balconies, kitchens, household and bathrooms with high humidity, for decorative decoration of internal walls. Withstands temperature extremes and prolonged dampness.

The instructions on the package indicate for which work the Ceresit brand is intended, what are the norms for the consumption of the mixture, what layer the solution is applied to. Stamps are denoted by the Latin characters CT and numbers.

Properties of facade and decorative plasters

- ST35. Ceresit dry mix, mineral-based decorative plaster (fractions of 2.5 and 3.5 mm sizes) to create a bark beetle texture. The solution is applied in a thin layer, the mineral base is available in several color options. The coating properties are frost resistance, strength and impact resistance, vapor permeability. The composition is intended for application on brick, concrete and plastered surfaces, suitable for subsequent painting.

- ST 36. SeresitST 36 decorative plaster is used for the protective and decorative finish of facades and internal walls, is applied to brick, plaster, concrete surfaces. The material allows you to create original surface textures, used for facade thermal insulation. Suitable for surface painting with silicone, silicate and acrylic compounds.

- ST 72/73. Two types of Ceresit paste, facade plaster for thermal insulation with mineral wool and polystyrene plates, to create a pebble effect. The materials are resistant to biological corrosion, are characterized by vapor permeability, strength and durability.The grain size is 2.5 and 1.5 mm.

- ST 77. Mosaic plaster with stone multi-colored inclusions (fractions of 1.4-2 mm). Used for interiors and facades, applied to gypsum, cement, drywall, concrete and chipboard. Coating properties: durability, resistance to abrasion, exposure to the sun. Marble or quartz chips have a natural or artificial color cast. The polymer in the mixture is transparent.

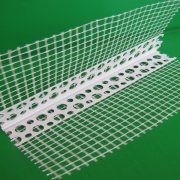

- ST 190. Glue mixture for fixing mineral wool insulation boards and forming a base layer. Facade plaster CeresitST 190 is suitable for winter and summer use (in different versions of the component composition), it is resistant to frost and damp. Reinforcing fibers are present in the composition, therefore, after hardening, the coating becomes strong and resistant to shocks, mechanical destruction. Properties: high adhesion, elasticity, vapor permeability. The material is environmentally friendly for people and the environment.

- ST 137. The facade plaster CeresitST 137 is intended for interior decoration inside and outside the building, has a pebble texture and is applied for further painting. Characteristics: impact resistance, frost resistance, vapor permeability, resistance to moisture and weathering, environmental safety.

- ST 174. Pebble plaster based on silicone for work with external and internal walls, with bases of concrete, gypsum and brick, for coating cement-sand surfaces. The component composition includes synthetic resin, mineral filler and modifying ingredients. Properties: increased elasticity, resistance to mold and sunlight. Silicate-silicone material is additionally used to eliminate defects on the wall.

- DekorPlus. A powdery substance for the preparation of mortar, intended for interior work and facade design. The coating is notable for its impact resistance and external aesthetics. The plaster of this brand helps to create attractive textures of “lamb”, “fur coat”, “bark beetle”, has insulating properties and is resistant to temperature extremes. After drying, DekorPlus is tinted with acrylic or silicate paint.

Application Tips

- Read the instructions, make a careful calculation of the costs of the material, purchase a mixture of one batch in the right amount. Try the application technology on an inconspicuous area of the rough wall, feel the solution, practice the application.

- Clean the working surface from the old finish, degrease and prime. On each wall, make a separate portion of the solution, if you are working not with a ready-made solution, but with a dry mixture. Related materials (adhesives, primers, putties, paints) choose from the Ceresit line.

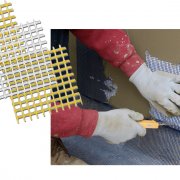

- Determine the thickness of the layer and proceed with the application of plaster. Make sure that the coating does not exceed the size of the impregnation fraction in thickness. Wait for partial drying (the solution does not stick to the instruments) and proceed to the formation of the texture. Make multidirectional movements with a grater of plastic and wood. Lightly click on the tool. The photos and videos in this article will demonstrate the technique of creating patterns.

Important!

When choosing facade plaster, consider the climate of the region of residence. If you are constantly raining, work with compounds based on acrylic or silicone. In hot climates, silicate and mineral plasters win: they are resistant to sunlight, retain color, do not fade.

In an area with an aggressive sun, do not use radically dark or bright shades of paint: this will lead to cracking of the dark coating and the dimming of the bright color. A universal option for the Russian region is elastic plasters. Pay attention to the base material: individual mixtures are designed for specific types of materials.For example, the composition of CT 24 is intended for integral coating of foam concrete and aerated concrete, and on lightweight concrete it is advisable only to fill in the recesses and chips.

The component composition of elastic grades contains antifungal drugs, so the mixture is suitable for all substrates (concrete, brick, wood). Such compositions have water-repellent properties and last 30 years.