Reinforcing walls with a grid: rules, features, cases from practice

Wall mesh reinforcement is almost always done. Indeed, the quality result will depend on the correct implementation of the technology of work.

It performs a purely practical action, strengthens the applied coating and there is nothing to replace it with. Today we will tell you what reinforced mesh for walls can be, what are its differences, and you will get acquainted with recommendations for its installation. Also in the video in this article you can watch and see in practice how and what is being done.

The content of the article

Cases in which walls should be reinforced

The mesh for wall reinforcement is sometimes not applied. But in most cases it should still be used.

These cases include:

Cracks on the outside wall | Thanks to mesh reinforcement, the volumes of large cracks are significantly reduced, and if they are not large, then they can be removed altogether. In addition, reinforcement is an excellent prevention for cracks when used in the construction process. |

Roughnesses on the wall | During the reduction of irregularities on the wall, you can encounter large differences, in order to mask them you need to impose a thick layer of plaster. Given that the plaster itself is quite heavy, there is a risk that such a layer may swell or crumble. |

Smooth wall plane | In such an optimistic version, reinforcement increases the density of the mortar to the wall. |

Reinforcing mesh for walls is available in several manufacturing options.

Each has its own parameters and let's immediately consider the range that retail chains offer us:

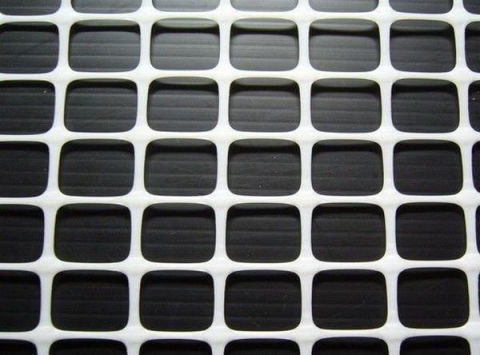

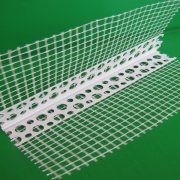

Masonry net | It contains plastic and polymeric substances, it has cameras 5x5 mm in size. Use it with brickwork. |

Universal building grid | In most cases, it is based on polyurethane. It can be of three types: small, with cameras 6x6 mm, medium - 13x15 and large - with size 22x35 each camera. The fine mesh is used in cases of reinforcing with both finishing and stucco mixtures, it has many applications, it can be used to perform plastering of any volume. Medium differs from small only in the size of the cameras. Large reinforcement is used when reinforcing large areas, premises for a warehouse and any large buildings. |

Armaflex propylene mesh | This reinforcement is based on polypropylene. It has reinforced nodes and 12x15 mm cameras. It is very durable and is applied to places where a high load falls. |

Propylene mesh 12x14 | The material of manufacture is polypropylene, cameras 12x14, or 22x35 mm. Very light and does not enter into chemical reactions. It is used both for plastering in the room itself, and outside. |

Reinforcing plurim | It differs from syntoflex solely by the parameters of the cameras, they are 5x6 mm. |

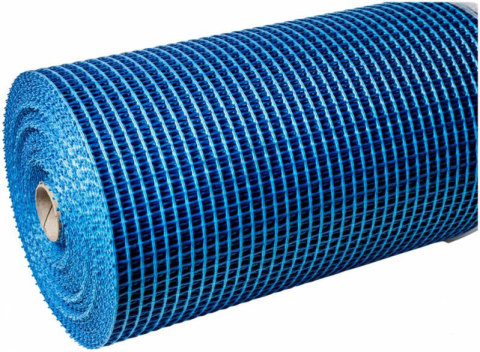

Fiberglass reinforced | It is created from fiberglass, which is processed in a special way (seeFiberglass plaster mesh - types and scope) The parameters of the cameras are 5x5 mm. It easily tolerates temperature changes and does not enter into chemical reactions, high strength, copes with maximum loads. It is used very often, since there are practically no restrictions on the use. |

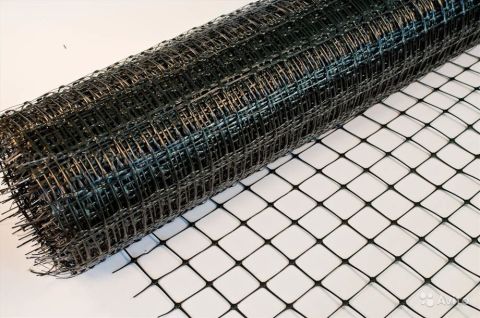

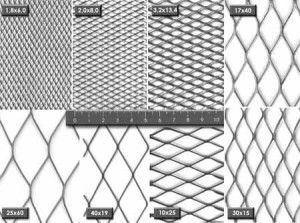

Steel mesh | Created from steel rods woven by knots, it has a large selection of chamber sizes (seePlaster grid steel - types and application). This reinforcement perfectly copes with the load, while it is used exclusively for reinforcement in the building itself, due to the fact that steel copes poorly with climate changes. |

Reinforcing galvanized fiberglass mesh | Such reinforcement consists of galvanized rods soldered by knots like steel, has a large selection of sizes, while it is more viable than steel and can be used not only indoors but also outside. |

Operation of reinforcement during plastering

Reinforced mesh for the wall can be installed in several ways. This is determined by the way in which the plaster layer itself is covered (by spray or coating). You can watch it in the video in this article and in the photo.

So:

- The bottom layer is reinforced by the means of the selected mesh, superimposing and slightly pressing it on the already laid plaster layer.

- The best way to apply the finish overburden is when the net is first attached to a dry bed thanks to special tools.

- If the amount of work is not very large, then directly the plaster layer can be used as a fastener. In these situations, it must be applied at certain points, solely to keep the reinforcement.

- At the end of this procedure, the plaster layer is distributed equally, at the place of work.

Recommendations for the selection of plaster reinforcement

The most important criterion for the selection of plaster reinforcement will always be the thickness of the mortar along the perimeter of the plane. Therefore, it is important to understand where the lowest point is.

This can be done using a special level. Having understood where this point needs to be estimated what will be the thickness of the solution layer.

Based on these measurements, you can choose the appropriate option:

- In a situation where the layer is not more than 20 mm and there are no rusts on the ceiling, it is possible to cover with a plaster layer in the absence of reinforcement. It should begin to actually set up the lighthouses.

- In a situation where rusts are found, or if it is planned to apply a plaster layer in the range of 20 to 30 mm, it is most reasonable to choose a fiberglass mesh, since the main purpose of this type of mesh is to save the surface from splits.

- If the thickness of the layer exceeds 30 mm, then it will be necessary to install a reinforcement of metal. Metal reinforcement was created to avoid peeling from the base under its own weight.

- In difficult cases, with differences in height of more than 50 mm, it is easiest to use other means, for example, consider the option of installing a suspended or suspended ceiling.

Using fiberglass for plaster

When purchasing this type of reinforcement, do not forget that the perimeter of the chambers cannot exceed 5x5 mm, and the density must be in the aisles of 110-160 g / m2. In addition, the composition of which the reinforcement is made is required to contain anti-alkaline elements.

Attention: When using this reinforcement, it must be borne in mind that the thickness of the plaster layer must be from 3 mm to 30 mm.

- Before starting work, it is important to divide the reinforcement into several tapes. Their parameters should be determined by the way that the reinforcement is planned to be located.

- In a situation where there are rusts, it is important that the grid is located as a whole canvas along the length of each seam.

- In the opposite situation, there is no strong difference in the way the grid is positioned; the most important thing is to ensure that the reinforcement covers the ceiling over the entire area

- To make the seam as tight as possible, it is better to cut the cut with a margin of 10-15 cm.

Fiberglass mounting method

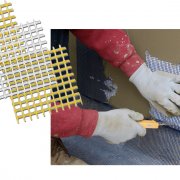

The mesh reinforcement of the walls is carried out by attaching the coating to the base plane (seeHow to fix a stucco mesh to a wall) First of all, the initial layer of plaster should be applied to the workspace. It is on this layer that the reinforcement itself is later laid and sunk.

After fixing the reinforcement in the solution layer, a second layer should be applied. It can be done both in one run and in two, taking a break for a while until the primary layer dries. From the above it is clear that the stelosette is always placed between two layers of plaster.

Workers at a construction site often use screws or staples to attach the glass mesh to the wall, and only then apply the plaster mortar directly to the mesh. This is often done in cases where it is necessary to apply a thin layer of the solution.

Due to this, it turns out that the grid is between two layers of plaster. But in cases of applying a layer with a thickness of more than 10 mm, the mesh will inevitably be pressed to the base, that is, it is not the mortar that is strengthened, but the wall or ceiling.

The most correct is the following procedure for applying fiberglass reinforcement:

- Determining the markings for lighthouses, you need to drill holes and hammer them with dowels.

- Leveling and leveling through screw caps across a series of beacons.

- Lay the initial layer of the mixture over the entire volume of the grid.

- Through the caps of the screws, the reinforcement should be laid on a new layer of plaster mixture. Next, on the nearest plaster layer, also lay a grid and so on around the perimeter. It is recommended to impose adjacent canvas blades overlapping them by at least 1 cm.

- After this procedure, plaster beacons are already installed and the process continues as usual.

Attention: Speaking about the fiberglass mesh for stucco solutions, it is important to mention that the layers should be applied as evenly as possible on the entire surface of the grid, the layer should be aligned in different directions, starting from the center.

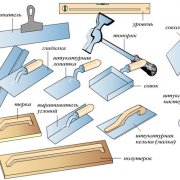

The edges of the canvas in the corners are best pressed with a rule or a wide spatula, while the second spatula is used to smooth the net from top to bottom across the wall.

Metal Reinforcement Guide

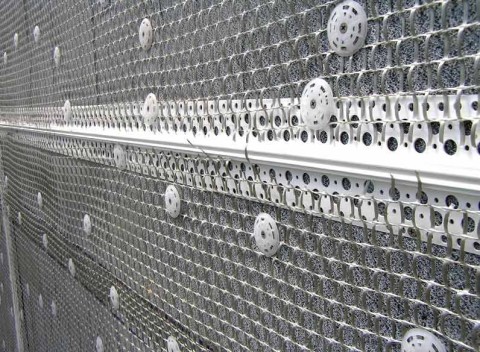

Metal reinforcement for plaster is used if necessary, coating a layer with a thickness of more than 30 mm. The most appropriate choice would be a galvanized metal mesh, with the dimensions of the chambers 10x10 or 12x12 mm, in some cases a grid of expanded metal is suitable, with dimensions of 10x25 mm each chamber.

The presented reinforcement for plaster stands out among others for its light weight, and with very thin layers it easily takes the desired shape of the surface, moreover, it is very easy to cut and it does not leave a print of corrosion.

Metal Mesh Overlay Method:

- Divide it into the canvas, dissecting with metal scissors. As mentioned earlier, if there are rustics on the ceiling, then the grid must be placed along the seams with whole canvases.

- Make places for fixing the dowel using a drill. The depth of the hole must be calculated so that it was approximately 2-3 mm larger than the dowel itself. The holes should be located at a distance of about 30 cm from each other.

- After this, we insert the dowel into the made passages, and then using the mounting tape and screws we fix the grid on the surface. The most important thing is to firmly fix the extreme points of the grid. The canvases that are nearby are best lapped, about 10 cm each. In the case of sagging mesh, it is desirable to drill more slots for fixing the mesh in these areas.

- Plaster beacons made of metal are required to be placed on a reinforced mesh.

- Since the thickness of the plaster layer will be more than 30 mm, it is necessary to impose it in two stages, waiting until the first layer dries.The initial layer of plaster is allowed to be thrown on a metal reinforcement with an ordinary trowel to press the mixture and it passed through the mesh, clinging to the surface. After this, apply the next layer, the main thing is to wait for the first layer to dry.

When a galvanized metal reinforcement of expanded metal type is used, the smallest thickness of the plaster layer is determined by the height of the reinforcement itself. Based on this, we can expect that the thickness of the grid from

Reinforcement with grids of monolithic walls and brick is not fundamentally different. Even the mounting system is one. The main thing is not to rush and make the correct coating tension. Its price is not large and you will not incur large costs. Moreover, you can do it yourself and ultimately get high-quality coverage. The instruction will help to do everything right.