How is puttying slopes

Putty of window slopes is quite a responsible job, because the slope is not covered and immediately visible. All flaws are striking. So everything will have to be done carefully.

Putty for slopes is in retail, you need to choose the right option and after that already do the work. Today we look at just that. In the video in this article, you can see the progress of the work and understand the details from the photo.

The content of the article

Work Execution Rules

Putty for slopes should be immediately identified. After all, the slope can be inside a heated room and can also be in an unheated room. So you need to immediately make a choice of the types. How to putty the slopes of window openings will depend on the location.

There are two options here:

| Putty for exterior decoration | It has a larger fraction, but tolerates low temperatures and high humidity. Cement is most often used as the main component. |

| Putty for interior decoration | This material has a small fraction and allows you to make the plane perfectly smooth. But for exterior decoration it is not worth using. Service life will be short. |

Attention: before buying, the instructions should be studied and immediately pay attention to the temperature conditions of use.

Tool

When carrying out any business, tools will be required, and in this case, plastering slopes will not be an exception. The tool kit directly depends on what materials you decide to use.

But in any case, you will need:

- Level;

- Pencil;

- Rule of aluminum;

- Roulette;

- Five centimeter spatula;

- Malka from metal or plywood;

- Master OK;

- The capacity in which the solution will be poured;

- You may also need a pickaxe hammer.

Too long a level does not fit. It simply can not fit between the windowsill, as well as the jumper. But working with a short one is hard. You need to choose a middle ground - more precisely, a level of about a meter.

- For auxiliary work, stock up with a knife and a gun with a sealant. It is possible that you will need a cylinder with mounting foam, which will blow out the gaps between the opening and the window frame.

- If you use a ready-mixed mortar for cement-based plaster, you will need a grater and a grater.

- If a Rotband is used in the work (see Rothband plaster - the best gypsum mixture for leveling walls and ceilings) - have a sponge grater by hand, a spatula of forty-five centimeters and a trowel.

- Shoes and overalls should not bother you and restrict movements. Be sure to wear a hat, this will protect you from falling solution on your head. Since the worker’s hands are in contact with the solution, you need to get nitrile tight gloves.

If you are serious and want to understand the intricacies of a process such as plastering slopes, lend or make a stucco goat of planks with your own hands. This is necessary for security, and the work will argue. A bad idea to do the work is on a stool or stepladder. In this case, you will have to spend many times more energy and time.

Sound insulation and insulation of slopes

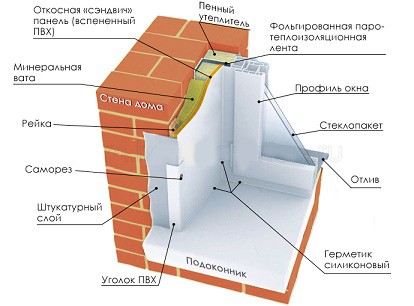

Depending on the quality and design of the installation of a door or a double-glazed window, there may be gaps of various sizes between the wall and the box.

Attention: If they are more than five centimeters, which can often be found in old buildings, then the slope plaster will include several stages - insulation and sound insulation.

So:

- The gaps between the wall and the box are filled with special heat-insulating material. Usually it is slightly moistened with a gypsum solution and rammed around the entire perimeter, leaving only a small gap for filling with the main solution.

- If, after the window is installed, sounds are clearly heard from the street, then the gaps are additionally filled with material that performs an insulating function.

- If the installation was done correctly, then there will be practically no holes between the walls and windows, but they are filled with mounting foam. Immediately from the moment of drying, you can proceed to the plastering of the slopes of the windows.

Preparation work

Before moving to the main work, you need to thoroughly prepare. From what quality was given to this stage, long-term finish and usability will depend.

So:

- It is best to install a window sill even before the start of plastering work. In the future, this will allow not to close the gaps between the side slopes and will increase the mounting strength. But in this case, it should be reliably protected from ingress of the solution and mechanical damage. To do this, sheets of drywall are covered with top, if any, in the house or with a dense layer of paper.

- If an old layer of plaster, stains or paint remains on the window openings, they must be removed. Plaster should be laid on a solid wall, and not on dust or dirt;

- Window blocks are also best covered with film. In a single production, you can take the film by attaching it to the window with ordinary masking tape. You also need to protect the handles, radiators and other accessories, wrapping everything with paper;

- After cleaning, the excess foam is cut with a knife;

- To improve the adhesion of the applied solution and base, the surface is coated with a deep penetration primer. Her choice will depend on the building materials (drywall, concrete, brick, and so on) of which the window opening itself is made. Consult with knowledgeable people or with the seller in a hardware store;

- After that we carry out vapor barrier. On the inside of the wall, the foam must either be sealed with a special film, or a silicone frost-resistant sealant should be applied to it.

- The sealant must be applied to a dried surface, otherwise it will not lie. Its excess is removed immediately. If it dries, it will be problematic to wash it.

Attention: If you do not perform vapor barrier of the foam seal inside, then over time the foam will begin to get wet from condensate and lose its protective properties, and in some cases even collapse. Then the slopes and windows will begin to sweat, and because of the frames it will begin to pull in a draft.

- After that, it was time to make the malki. Malka - a pattern by which plastering is carried out. If you look closely at the slopes, you will see that they are not just straight, but slightly expand inward, thereby forming the dawn of the window.

- Most often it is made from a plywood piece. This is narrow plywood, whose length is five to ten centimeters more than the slope, about fifteen wide. There is a cutout on one side. During operation, it is this part that will move along the slope, and the second - along the installed beacons.

Attention: Thanks to this device, after removing the applied solution, the slope is smooth. You will also need to make another cutout through which window hinges will go.

- The manufacture of malki must be approached especially carefully. Work surfaces must be perfectly even. It is advisable to slightly chamfer so that the plywood does not chip during operation. Professionals use aluminum metal fry, which are made to order.Of course, you can do without this device, but you can not guarantee that the slope angles in all places will be the same.

General recommendations

Puttying the slopes is done slowly and there are recommendations:

- To work with cement mortar, the temperature in the room should be about 5 degrees, for a rotband - ten. The stucco mixture must be prepared in accordance with the recommendations from the manufacturer. A solution whose shelf life has expired is better not to use.

Attention: do not cook large volumes immediately. This is especially true for plastering with a rotband, which requires a fairly quick technique.

- Before proceeding with the plastering of slopes, it is necessary to clearly calculate the required amount of solution. Its volume is calculated based on the area of the slopes, as well as the thickness of the plaster layer.

- Plastering slopes, basically, is carried out according to the same rules as finishing a simple wall, that's just the calculation of the windows is done by little.

This is done as follows:

- First you need to determine where the slope angle will be;

- We press the malku tightly against the sash of the window, and gradually smooth the solution until the smooth angle and surface are obtained;

- Carefully remove the rule by slightly shifting it along the corner.

Finishing - is carried out in the same way as for simply plastered walls. Before starting this work, it is better to install a perforated angle on the corners, so the edge will be protected from mechanical damage.

What to do if there are plastic windows

There are certain recommendations on how to plaster slopes in such a situation.

- After the slope is completed, but the solution is not completely dry, you need to use a spatula to cut a groove between the frame and the slope (its width will be three to five millimeters), and then fill with silicone sealant. The frozen mixture will act as a protective pad.

- The thing is that plastic products (especially PVC profiles, which are not of the highest quality) expand under the influence of ultraviolet rays. At the same time, they expand so much that cracks can appear together with the slope. Silicone is a plastic material that will not allow this.

- It is also necessary to pay attention to grouting the plane with a grater. You can scratch the plastic. Therefore, during grouting, it is worth putting a cardboard on the PVC plane. She will protect about damage.

Puttying the slopes with your own hands is not a difficult thing, but painstaking. The most important thing is to withstand the right angle. If you order masters, the price will be high, so doing the work yourself can reduce costs and do everything as efficiently as possible.