How is sanding walls after puttying

How to sand the walls after puttying? Without sanding the wall after applying putty on it, the finishing process is considered to be performed poorly. This work is necessary to give the surface a perfectly even coating, for further decorating it with other finishing materials.

The article suggests getting to know how and how to putty putty when repairing a house.

The content of the article

Features of surface grouting after puttying

Everyone who begins to make repairs in the room should understand that the painting of the surface of the walls (see How and what is the painting of walls) is carried out only after cleaning putty. This process is one of the main stages of decorating the premises - the embodiment of design ideas into reality will depend on its quality. But it’s quite difficult to determine what kind of skin is needed to grout putty so that after painting the surface is free from flaws.

Abrasive sanding putty should have the following features:

- Paper abrasive when leveling surfaces with puttying material is the main tool for the final cleaning of walls and ceilings before painting or gluing wallpapers. To perform such work, certain knowledge and skills are required.

The instruction for leveling the walls suggests carrying out the process in several stages:

- Applied to the surface starting putty, which eliminates large flaws in the plaster layer.

- After it dries, the finishing ball of the putty mixture is laid to get a perfectly flat plane.

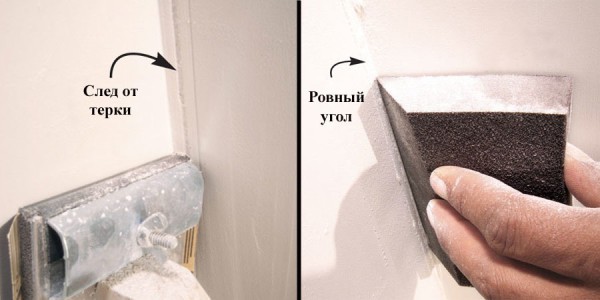

Tip: Even the best craftsmen will not be able to get a perfectly smooth surface after putty, without stains from a spatula. To remove these flaws, the last ball should be completely skinned until the plane becomes as even as possible.

Sanding is done with a special grout net or paper abrasive. This is done with your own hands or with the use of special electric grinders, which will be needed to decorate large areas, but at the end of the operation you can not do without working with a sandpaper manually.

The advantages of the machine method:

- speed of work;

- convenience.

But in the end, the machine can not achieve quality, as with the manual method.

Advantages of abrasive mesh:

- The presence of perforation on the surface. In this case, building dust passes freely through the holes, which allows the mesh to not clog, like emery.

- Easy to replace pieces of material as they wear.. The degree of wear is determined by such characteristics as:

- the mesh is torn;

- work efficiency decreases.

- The material is purchased in the right size., this eliminates additional product refinement. The main thing is to choose the right piece in size.

The disadvantage of abrasive mesh is the high price.

When using sandpaper:

- The disadvantage is the constant clogging of the material when polishing the surface with construction debris, which increases paper consumption compared to the grid.

- Advantages - a wide range of products. It can be purchased:

- in pieces;

- in rolls;

- small rollers.

Tip: When purchasing ready-made cut pieces, it should be borne in mind that the cost of sandpaper will be more.

What tool will be needed for grouting putty

Before sanding the putty, you need to purchase the necessary tools:

- Reliable stepladder.

- Carrying, to illuminate the surface.

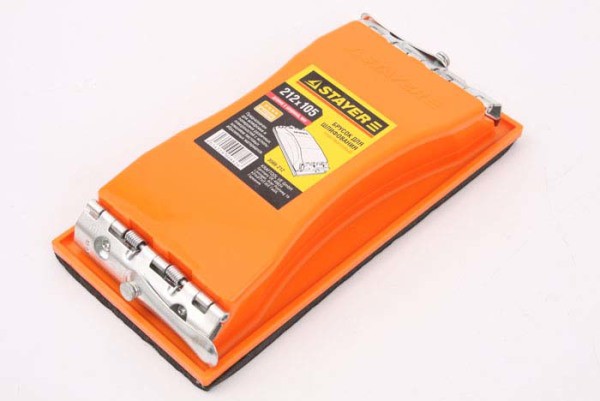

- Sandpaper or abrasive, which is installed on the skater.

- Hand-skinned skater.

- Sanding sponge with pre-cut corners.

- Small spatula.

- Items for the protection of the master when performing finishing work:

- gloves

- respirator;

- headdress.

When choosing an abrasive mesh or sandpaper, it is necessary to take into account some nuances:

- Starting grinding should always be done with coarse-grained skins.

- Fine grains are used for the finish.

Grain sandpaper is divided into several types that have a special number according to FERA standards:

- Macro sizes are assigned numbers from No. 20 to No. 240.

- Micro sizes correspond to numbers from 240 to 2500.

Wherein:

- For grouting the first layer, most often, a skin is used under the numbers from 120 to 180that depends on the condition of the surface being trimmed.

- When sanding the finishing putty, smaller sandpaper is usually used, with numbers from 240 to 280.

- The process of leveling walls for painting can be performed with materials and with higher grit.

Tip: Keep in mind that the higher the grit number, the more sandpaper the finer the grain.

Abrasive nets are also subdivided into numbered models.

For instance:

- Large irregularities can be eliminated by a format whose indicator is 60. It is used for sanding the walls after applying the first layer of putty.

- For finer processing of the wall, as under wallpaper, for grouting putty, such a skin is selected with a number from 100 to 120.

- For painting, the number of the skin can be taken from 120 to 150.

How to sand wall surfaces

The surface grinding process consists of several stages:

- The putty surface is inspected for voids.

- The presence of dry areas is determined.

- Before starting work, put on protective attributes.

- Walls or ceilings should be sufficiently lit: a portable lamp is connected and installed.

- With the help of a spatula, large mounds are removed.

- Primary grinding is carried out. The process begins from above, gradually the tool sinks to the bottom.

Tip: When fumigating, it is necessary to process areas of a small area, about 1-1.5 meters.

- Sanding should be carried out by two types of tool movement, while uniform rounded hand movements are performed as in the photo:

- "up down";

- "Left and right."

It is impossible to grind the same place for too long, this can cause irregularities on the surface. If a cavity forms on the wall, it can be skipped and putty in the future.

- After sanding the main area of the wall, attention is paid to corners and other hard-to-reach areas. For their processing, special skins are used that have beveled corners or bent sandpaper.

- All garbage is removed in the room, wet cleaning is done.

- The surface is checked for flaws, deep depressions, if necessary, are puttied.

- Finishing sanding the walls with finer abrasive grain. Hand movements are softer than before. At this stage, special attention should be paid to surface lighting, after finishing grinding, the quality of surface finish is determined.

- Garbage is removed.

- The walls are primed (see Primer walls and all for that matter).

- The final decorative coating is applied.

Puttying sanding is not too complicated and expensive. Using simple tools, you can perform all operations no worse than mechanical devices. And how to skim the finishing putty, how the process is performed correctly, the video in this article will tell.