How to spread putty: instruction

How to putty the walls and ceiling, to choose the right material and its quantity, to prepare the mixture, to apply and grout, is of interest to many beginners in the construction business. The article suggests that you get acquainted with some of the stages of the work yourself, will tell you how to properly perform the initial stages of operations.

The content of the article

Features and types of putty

Putties are finely dispersed building compounds that have a different consistency that affects the area of its use.

According to the degree of readiness, the material happens:

- Ready to use. It is implemented in a special container.

Advantages of the composition:

- no time limit for use;

- no cooking time is wasted;

- no additional tools needed.

- Drysold in bags or packages.

The advantages of the mixtures are:

- easy to make;

- you can cook any degree of viscosity;

- convenient to store and transport;

- not high cost;

- long storage period.

Disadvantages:

- additional time and tools are needed to prepare the solution;

- it is important to observe proportions and breeding technology;

- limited time use of the finished mixture.

How to calculate the amount of putty

Tip: Before calculating the putty, its consumption per square meter, you should determine the type of material used.

This takes into account:

- The highest consumption for wall decoration is starting putty, 30 kilograms of coating is spent on processing up to 20 square meters of surface. With a large curvature of the walls, the consumption of material can increase. The rate of putty consumption is determined by the amount of surface roughness to be processed.

- When decorating the walls with universal putty, a bag weighing 20 kilograms is enough for about 24 square meters of area. In this case, after such finishing it is possible not to use finishing putty, but the ideal surface will be obtained after the finishing mixture, the consumption of which is minimal and 20 kilograms of mortar can be enough for an area of up to 50 square meters, which is almost two times less than the previous types of material.

To calculate the putty consumption per square meter:

- The total surface area to be trimmed is calculated.

- Knowing the entire area and the approximate consumption of the material, its quantity is determined.

For example, the surface area is 100 square meters, for its decoration you will need:

- starting composition - 150 kilograms;

- universal - 100 kilograms;

- the finish line is 30 kilograms.

How to spread putty

For high-quality coating, first of all, it is necessary to clearly know how to dilute the putty, the proportions of the solution for surfaces of different materials. Each type of composition has its own dilution instructions posted on its packaging. However, all the nuances are not always disclosed in it, and besides, when repairing, the situations can be very different.

For instance:

- When applying a thicker layer of putty, it will be more convenient to use a thicker solution, which requires the use of a slightly less amount of water than indicated by the instruction.

- When coating drywall (see Drywall putty: practical tips and useful information), the leveling layer of putty is usually very thin. To do this, the solution is diluted with a liquid.

Tip: Before kneading putty, it should be remembered that a thicker composition hardens faster.

- It is better to dilute the mixture in small portions, which will prevent its hardening even in the tank, and it is impossible to use the reconstituted composition. The reasons for this are:

- the formation of small lumps, which will be impossible to get rid of;

- the solution will lose many of its qualities and after application the finish will last very briefly;

- the price of such repairs will cost much higher.

- During mixing, water is poured into the dry mixture, and not vice versa.

- To breed putty, it is best to use an electric drill with a whisk or a special construction mixer. The power of the tool should be at least 500 watts, for small batches and 1.5 kW when performing repairs constantly. The number of revolutions of the drill should be large.

- Mixing of the solution begins with small revolutions, the whisk gradually deepens and the mixing zone expands.

- After the consistency of the solution becomes uniform, the number of revolutions increases to maximum.

- The composition remains at rest for several minutes.

- Again, everything is mixed, which will increase the uniformity of the mixture.

To better get acquainted with the process of how to make putty yourself, you should first watch the video in this article.

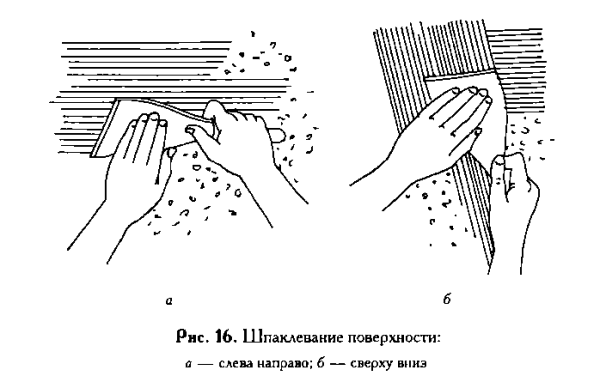

How to learn to putty walls

Learning to putty on your own is not too difficult. But in any case, training should be accompanied by practice. Before starting work, a small batch of the solution is bred, and the process for the first time will occur very slowly.

Then:

- For experiments, the most inconspicuous angle is chosen.

- Two spatulas are purchased:

- one solution is applied to the surface, its width is selected over 30 centimeters;

- the second putty is applied to the blade of the first, half the width of the main one.

- To warm up, you need to practice applying material from one tool to another. As soon as the solution does not fall to the ground, you can begin the main work.

Tip: When applying the solution to the wall, it is necessary to maintain a large angle of inclination between the spatula and the surface, which will reduce the thickness of the putty applied.

- At first it’s worth practicing by applying a thin layer - after that, the errors are easier to correct.

- After the solution has been developed, the working container and tools must be thoroughly washed to an ideal cleanliness, which will prevent hardened particles of material from entering the new composition and scratching the surface when the solution is applied to it.

How putty is rubbed

Grouting the walls after the putty is over is an important step in preparing the surface, which is especially important before painting it (see How to putty walls correctly for painting - a detailed description of the process) In this case, it is necessary to choose the right sandpaper to clean the putty.

You can not polish the walls under the wallpaper, with the exception of the glossy variety of material and silk-screen printing.

When leveling the walls:

- Plaster eliminates large level differences.

- The starting layer of putty makes a more thorough alignment.

- Top coat (seeFinishing putty: how to apply qualitatively) mortar performs the most delicate work and allows you to achieve absolutely smooth walls.

But on the surface there are not too noticeable level differences, small tubercles and depressions, scratches, traces of a spatula blade and other defects and flaws. To eliminate these shortcomings, it is necessary to perform the final processing of the finish layer - to grind it with abrasive material.

To do this, you can use various materials for grouting:

- Sandpaper and fabric.

- Diamond nets.

- Other abrasive materials.

You can do the work:

- Manually.

- Using machines.

Putty grouting options can be:

- Manual sandpaper. The cost of this method is the smallest, and the result can be obtained with the right approach, quite good. In this case, the paper is fixed on a special wooden base with a flat and smooth sole with clamps or fingers, which allows you to quickly, if necessary, replace the abrasive, and then the surface is ground in circular motions.

- Hand abrasive mesh. The difference between this method is the use of mesh as an abrasive, not sandpaper. Its advantages:

- not clogged with dust;

- longer service life.

The cost of the grid is higher, but this is offset by a decrease in material consumption and convenience, which makes the overall performance of the work higher.

- An electric grater where paper moves like a belt on shafts. Due to the large length of the emery strip, it wears out more slowly, and a mechanical drive increases the speed of work.

- An electric grater with a mesh installed in it. In this case, friction arises from vibration and displacement of the working surface of the tool from one side to the other relative to the handle.

- Electric grater. Friction occurs on a rotating plane coated with an abrasive, which can be a grid and paper.

In addition to paper and mesh found:

- Stones such as pumice.

- Diamond surfaces.

- Notched Coatings.

- Material with crushed stone.

Putty grouting instruction is as follows:

- If there are irregularities on the wall and a large number of defects, the largest brand is taken - P60 or 20-N.

- Sandpaper or mesh is clamped on a grater.

- When processing, it is impossible to put pressure on the tool too much.

- The grater moves in a circular motion throughout the plane, as in the photo.

- Work is carried out until the surface acquires uniformity, without visible flaws.

- The sandpaper brand changes to a smaller one and the wall is processed again.

- To obtain a smooth plane, which is necessary for painting, the smallest paper 10-H or P120 completes the process.

Tip: Use a respirator and safety glasses when working.

- Hard-to-reach places and corners are best handled without using a bar or grater. Special devices with sharp corners are used.

- With large volumes of finishing surfaces and short periods, it is advisable to use electric graters.

- At the end of all work, the walls are wiped with a rag or the dust is removed with a brush, or removed with a vacuum cleaner.

How to glue baguettes on putty

In addition to puttying the walls, this material can perform other operations. How to glue baguettes on putty?

The order of work is as follows:

- One baguette is taken and applied to the wall so that it can stick on all planes.

- Marks are made with a pencil on the top and bottom along its length.

- This is repeated on another wall.

Tip: With this method of mounting baguettes, the miter box is not necessary. You should start gluing the baguette from the corners, these are the most difficult sections that take more time.

- Two intersecting lines are obtained. A baguette is applied to them point-blank to the wall, and marks are made on the baguette at the intersection points.

- A line is drawn through them.

- With a sharp wallpaper knife, the baguette is cut along this line.

- Two corner cuts are obtained.

Tip: Baguettes are easily cut with a sharp knife, but care must be taken to prevent nicks. When cutting, a small nuance should be taken into account: when cutting the inner corner, the knife blade should be tilted to the baguette, and the outer one is tilted in the opposite direction.

- The joint is checked, while both baguettes are folded at an angle, without the use of glue or putty.

- The baguette is glued to the wall and ceiling.

- If an error is detected, the situation is corrected with the help of an emery cloth, which processes the sides of the baguette.

- Finishing putty is applied. For this:

- material is put on a spatula;

- distributed evenly on two sides of the ceiling plinth, the layer thickness of one centimeter.

- The baguette is put in place, pressed in such a way that there are no fingerprints.

- Excess putty is removed with a spatula and the baguette is washed off with a sponge that is moistened with water.

- If the walls are not even enough, it is not necessary to press or bend the baguette, it is better to fill these cracks with putty and immediately gently wash it with a sponge.

Correct dilution of putty, accurate application of it on the wall, will allow you to repair the premises quickly and efficiently.

If the starting putty, then it is more difficult to breed it in the sense that it should turn out ideal. That is, and not liquid, and not too solid. Less problems with finishing putty. I personally breed so that it is sufficiently liquid, then it is easily and simply put on the starting putty. But experts know that they are not advised to do so, because it is not professional. Well, I'm not a professional, the main thing for me is that the wall is flat. 🙂