Aerated Concrete Finishing: Material Overview

Wall decoration of gas silicate blocks can be external and internal. A variety of materials are used in the work, which may be similar in their technical properties and characteristics.

The content of the article

Exterior finish of gas blocks

Before deciding on finishing material, you need to get acquainted with the types that are most often used for exterior decoration.

Exterior finish of gas silicate blocks can be performed:

- Siding.

- Brick.

- Decorative panels made of metal.

- Stucco.

There are various photos using these materials in decorating. Combination is quite common.

For example, stucco with natural or decorative stone; brick siding with decorative panels and other interesting combinations.

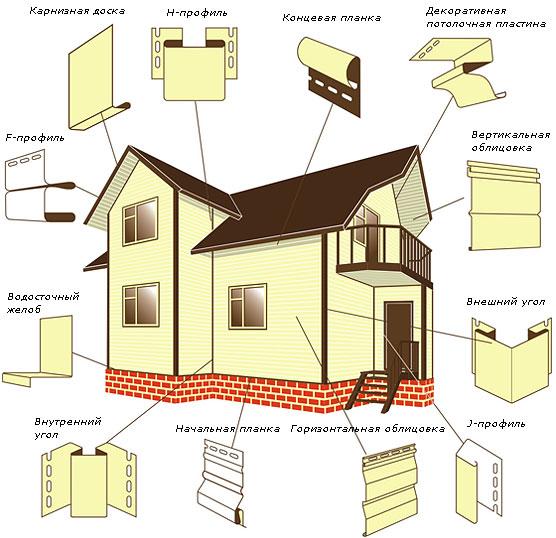

Siding decoration

This material has several manufacturing options.

He can be:

- Vinyl.

- Wooden.

- Metal (aluminum).

- Ceramic.

- Basement.

Material Features:

- Siding for exterior decoration works has high moisture resistance.

- It does not allow air and noise to pass through and thus serves as a sound and heat insulating material.

- Its surface imitates brickwork, natural stone, wooden beam, ceramic tile etc.

- According to its performance, it can be matte or glossy.

- Siding does not absorb all kinds of pollution. It is cleaned quite simply with a simple rag dipped in water.

- Frost-resistant, and does not deform from temperature extremes.

- The life of the material is about 15-20 years. But it all depends on its proper use.

- The material is quite light and the installation process can be done by yourself.

Note. The most practical and tested time is vinyl siding. Its price is much lower than for other types of the same material.

Surface mounted siding

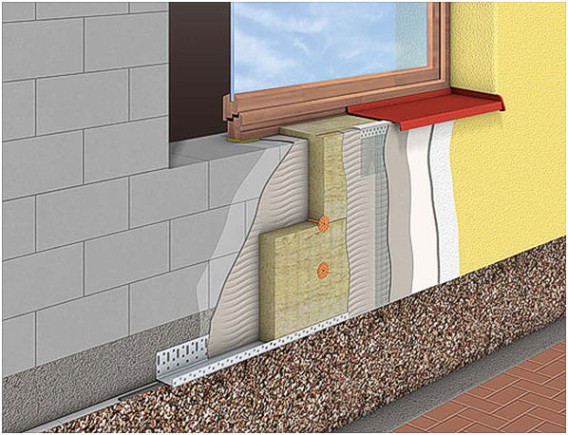

Initially, on the surface, a crate is made of wooden planks of the same thickness. In the process of such work, it is possible to simultaneously insulate the structure with the help of foam or polyurethane foam.

The layers of these materials should fit tightly into the cells of the crate.

On such a peculiar frame, strips or siding panels are mounted using:

- Building level.

- Self-tapping screws.

- Screwdriver.

- For cutting sizes, a grinder is used.

Tip. If the surface of gas-oil blocks is covered with OSB or plywood sheets, then you can mount the siding directly on them without additional manufacture of crates.

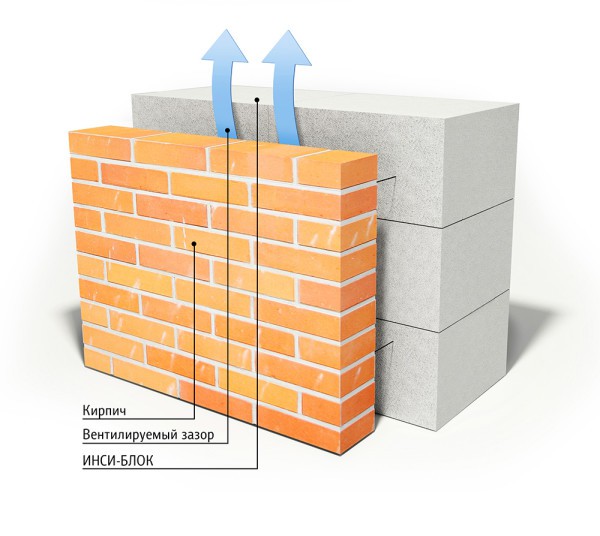

Brick in the decoration of gas silicate blocks

The methods for finishing aerated concrete outside the building are diverse, but brick is very popular (seeBrick home decoration: inside and out) It is an excellent material that is able to reliably protect the pores of gas silicate blocks from moisture.

Brick:

- Durable, and able to withstand various loads.

- It has a variety of manufacturing methods (simple brick or double).

- Does not absorb moisture and dirt.

- Not exposed to direct sunlight.

- Withstands various temperature differences.

- Frost resistant.

- Wear resistant.

- The life of this material is approximately 50 years, which makes the finish durable.

Note. Mounting a brick is not so simple. This requires some knowledge in this area.

Installation of bricks in the decoration of gas silicate blocks

Initially, brick laying is selected, which can be:

- In one brick.

- Half a brick.

- In two or one and a half bricks.

So:

- With its help, you can immediately perform insulation and insulation work.

- Quite often, mineral wool in mats is attached to the surface of gas silicate blocks using plastic frogs.

- Reinforcing pins are passed between the aerated concrete masonry, which will provide a lining of the lining with the wall.

Brick is laid using concrete mortar, which is prepared from:

- Water.

- Sand.

- Cement grade 400, which is particularly durable.

Tip. To make a decorative seam in the brickwork, add a special coloring pigment of the desired shade to the solution.

- To mix the mortar, it is better to use a concrete mixer, which will save time and effort.

To perform the bricklaying you will need:

- Building level.

- Master OK.

- Concrete mortar.

Spread immediately the trim around the perimeter is not worth it. Each row of bricks should be infused for a day.

This will give strength to the finish, the video shows an example of such work.

Decorative metal panels for exterior decoration of gas silicate blocks

Metal (aluminum) decorative panels for finishing gas silicate blocks are used most often.

They have excellent technical characteristics:

- They do not corrode like ordinary metal sheets.

- They are durable and reliable.

- Able to withstand a variety of loads.

- Light weight.

- Do not pass moisture.

- Easy to clean.

More details:

- Today there is a large assortment of such material, on the surface of which there is an imitation of masonry, wood (un-laminated or profiled timber), natural and decorative stone.

Note.

Aluminum panels are coated with a special polymer agent and their installation must be done very carefully so as not to damage the surface. For this, there are holes on the material for screwing in self-tapping screws.

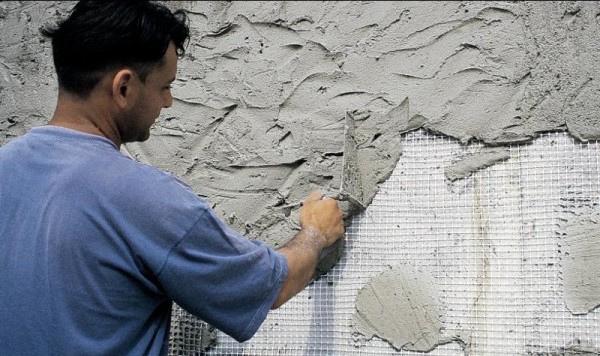

Plaster for external decoration of gas silicate blocks

Since gas silicate blocks have a porous structure, using plaster to finish them will be the best option. Its composition is able to penetrate holes of different sizes and at the same time completely fill them.

Characteristics:

- The properties of plaster have been known for a long time, along with the usual starting and finishing plaster, decorative, which has a large selection of shades and designs, is in great demand.

Note. If with the use of start and finish plaster most people do not have any difficulties, in order to apply decorative plaster it is necessary to prepare the surface.

Surface preparation for applying decorative plaster:

- It is superimposed on a flat surface, which is achieved by using conventional plaster or drywall.

Tip. It is undesirable to use drywall in external finishing work, since despite the moisture-resistant appearance, this material loses its properties and becomes susceptible to moisture.

To prepare a high-quality solution of decorative plaster, you will need an instruction according to which a specified amount of liquid is poured into a container of a certain volume.Decorative plaster, which is sold in bulk form, is added to it with a mortar and kneaded with a construction mixer, which will give the solution uniformity.

To apply the plaster you will need:

- Two spatulas: large and small.

- Building level.

- Sandpaper if necessary.

Tip. Apply decorative plaster to the surface in thin layers to ensure its uniform distribution on the surface and uniformity of shade.

Interior finishing work on the walls of gas silicate blocks

The interior decoration of the walls of gas silicate blocks can be made with different materials.

Namely:

- Drywall.

- Wooden clapboard.

- Decorative stone.

- Plastic.

- Natural agglomerate and so on.

In such works there are no restrictions on the use of one or another material.

Drywall in interior decorating

This material is considered universal. Without it, no repair work is currently underway.

It helps not only smooth the surface, but also prepare it for the use of other finishing materials.

There are several types of drywall:

- Arched, which is designed for making arches.

- Ceiling for ceilings and manufacture of multilevel structures on them.

- The wall with which the walls of the room are decorated.

All of these species can be moisture and fire resistant.

Stages:

- The interior decoration of walls from aerated concrete with drywall begins with the manufacture of a special profile metal frame on the surface.

- It is mounted on the surface with dowels.

- It turns out a kind of crate, both for the installation of plastic panels or siding.

For the installation of a metal frame and drywall sheets, it is required:

- Special profile.

- Dowels and metal screws.

- Rotary hammer and screwdriver.

- Building level.

- Hacksaw for metal or grinder.

- Pencil and ruler.

- Putty.

- Sandpaper.

Tip. All joints of sheets that are mounted on the frame are processed with putty and sandpaper.

Works:

- The interior decoration of aerated concrete walls using drywall ends with the decoration of its surface.

- Drywall can be plastered or wallpaper; to mount on its surface a decorative stone or ceramic tile.

Tip. To finish the plasterboard and auxiliary material for a long time, it is necessary to prime the surface with a special tool.

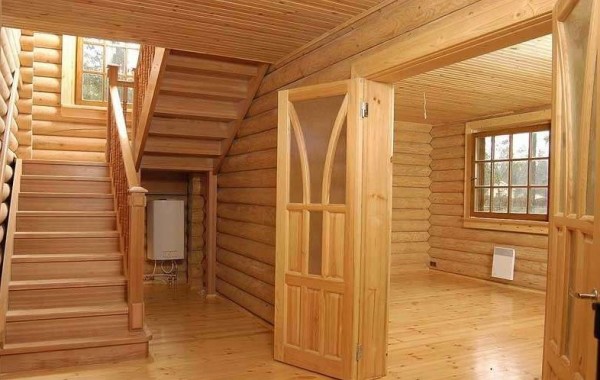

Wooden lining

Properties and advantages of wood have been known for a long time. It is an environmentally friendly material.

Quite often, the interior decoration of aerated concrete with the use of wooden lining is used.

Characteristics:

- This finishing material has the same properties as wood. It is mounted on a wooden crate.

Tip. If during the work it is necessary to carry out the insulation of the building, then this can be done using ready-made lattice cells into which foam or polyurethane foam is inserted.

It is worth considering that there will be a temperature difference outside and inside the room and for this reason, for the installation of a wooden lining over the first lathing with insulation material, the second is attached. It will create an air cushion and allow free circulation of air.