Facing panel with insulation - types and advantages

To increase the thermal insulation of the house and give it a solid look, you need to do a lot of work on the installation of insulation and decorative coating. However, material costs and labor costs can be significantly reduced using special materials - insulation panels with lining.

Their installation is faster and easier than a phased finish, and the effect is the same.

The content of the article

What are insulated facade panels

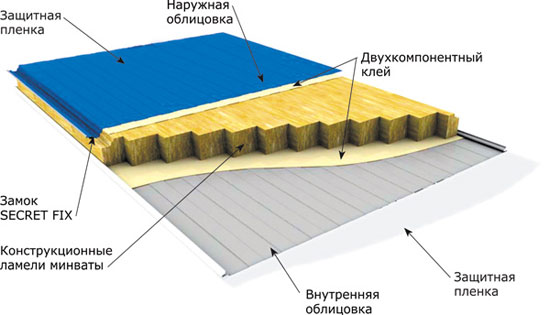

The principle of the structure of all such materials is the same - these are two-layer or three-layer panels, the basis of which is a heater (polystyrene, mineral wool, polystyrene foam, etc.), coated on the front with a decorative layer.

The most popular materials:

- Thermal panels with clinker tiles. They are different both in external design and in design.

The simplest are two-layer panels for cladding with insulation, in which glued on a polyurethane foam plate facing tiles. There are three-layer panels with a base layer of OSB, which gives them rigidity, as well as panels with metal embedded in them or molded plastic sleeves to facilitate installation.

- Expanded polystyrene panels with a decorative layer of stucco with colored marble chips. Their use allows you to create a seamless surface.

- Metal sandwich panels represent a "pie", the filling of which is a heater, closed on both sides with painted aluminum sheets or corrugated board with a protective film. Under the film, a pattern can be applied, creating an imitation of the popular facing materials - wood, stone, brickwork.

For reference. For thermal insulation and cladding, it is also possible to use SIP panels from oriented particle boards (OSB). But they require additional front trim.

Features of using insulated panels

The materials described are suitable not only for the decoration of newly constructed buildings, but also for the restoration of old and dilapidated buildings. For their installation, it is not necessary to strengthen or level the facade - just fix the crate on it.

And thanks to the light weight of the products and the thoughtful design, the cladding is easy to do with your own hands without the involvement of specialists and lifting equipment. But this is not their only advantage.

Advantages of Thermal Panels

Among the many advantages that thermal panels of any type have, the following should be highlighted:

- Reduced costs for winter heating and summer conditioning of insulated buildings up to 40%. A rather high price of the cladding pays off over several seasons, while the microclimate inside the house becomes much more comfortable.

- Light weight not only facilitates installation, but also allows you to transform the appearance of the building without creating a critical load on the foundation, which is very important for existing buildings.

Note. The weight of panels coated with clinker tiles or artificial stone depends on the thickness of the decorative layer. Before choosing the material for the restoration of the facade of an old building, you need to make sure that its foundation will withstand the load created by its weight.

- Regardless of the type of decorative coating, panels for insulation and cladding are highly resistant to external influences such as ultraviolet radiation, precipitation, temperature changes and its critical negative and positive values, chemical and mechanical damage.

- Durability, reliability, long service life without the need for repair.

- Incombustibility.

- Environmental safety of the materials used.

- Possibility of installation in any weather conditions.

Finally, for the consumer, a huge assortment of insulated panels is of great importance, the ability to choose a decor that matches the style of the house, choose the desired color and texture, “dress” the house in brick, stone, wood.

If you watch the video, you will see for yourself how simple this dressing is and how the appearance of the structure is radically transformed.

disadvantages

There are not many of them, but when choosing any material you need to know about the disadvantages that it has so that they do not become an unpleasant surprise during installation or operation.

We will not rank the disadvantages of the high cost of insulated panels. Firstly, the price range depending on their type is quite significant, and secondly, it is unlikely that you will be able to save by purchasing insulation and cladding separately and paying for the installation of each of them.

A significant disadvantage of two-layer panels can be considered their susceptibility to deformation during storage, which complicates the installation. Since both layers have different densities, structures, and reactions to changes in environmental parameters, the product can warp.

In this regard, three-layer facing panels with a heater it is more reliable, they are deprived of a similar drawback, but they also cost more.

Inexpensive panels imitating masonry, after installation, need to grout the joints with special compounds that protect the insulation from destruction. This is quite time-consuming and labor-intensive work, but it can be avoided if you buy cladding plates with seams already worn in the production.

Mounting Features

If the walls of the house are relatively even, the panels can be attached directly to them, leveling small irregularities with plywood or other materials lining during installation. Before its beginning, the most convex point is determined, and in accordance with it, lighthouses are attached to the wall using mounting foam.

This is quite dreary and long, it is easier to immediately install the leveling crate. In addition, it will allow you to create a ventilated space under the cladding, eliminating the accumulation of moisture in the insulation, and facilitate installation.

It differs slightly depending on the type and design features of the panels, but the general instruction is as follows:

- Around the entire perimeter of the building, a lower horizontal line is beaten, from which the lining will start from bottom to top;

- If installation begins above the base, then a base profile is mounted on it, which serves as a support for the panels and diverts rainfall flowing down the walls;

- A crate of dry, treated with antifungal impregnation of the bars is attached to the wall. The distance between them should correspond to the parameters of the panels;

Important! When mounting the frame, it is necessary to carefully monitor the level, ensuring that all the guides lie in the same vertical plane.

- Installation of panels is from bottom to top from the corner. If angular elements are available, they are attached first. If not, the ends of the panels are sawn for joining at an angle of 45 degrees;

- Fastening to a wooden crate is carried out by self-tapping screws, to a brick or concrete wall - dowel-nails. The length of the fastener should be 4-5 cm more than the thickness of the lining;

- Each subsequent after the first row is mounted so that the vertical seams are displaced. To do this, use additional or cut along the length of the panel. The front part of the panel is sawn by a grinder with a disk corresponding to the material, the insulation is easily cut with a knife;

- If grouting is necessary, this work is best done in dry weather at a positive air temperature.

Most panels have a hidden mount. If this is not the case, fixing holes are best done in the seams between the decor elements, and then masked with a suitable color composition recommended by the manufacturer.

Conclusion

Many developers and people who are puzzled by the external repair of the house, carefully choose cladding materials that meet their requirements for appearance and performance. In this regard, the insulated cladding panel is an excellent choice that allows you to “kill two birds with one stone”: to solve the problem of thermal insulation and transform the house beyond recognition in a matter of days.