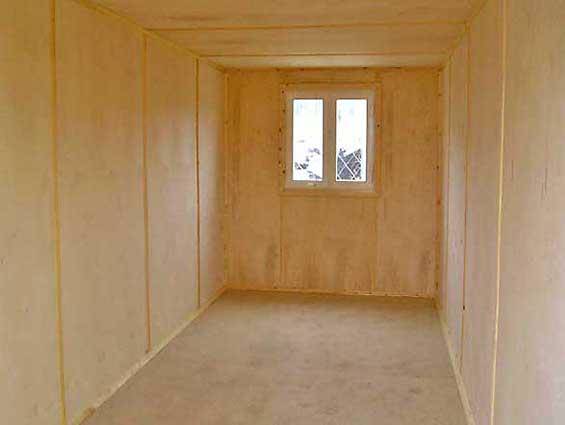

Lining the walls of fiberboard panels - how to do it

Even if the preparation of the walls for finishing is not entirely high-quality or you have no desire to do this, you can always find a way out. And one of them is the cladding of the walls with fiberboard panels.

They are laminated and do not require subsequent finishing, or without a decorative coating. In the latter case, the sheathed walls can be pasted with wallpaper.

The content of the article

What is this stuff

Each of us saw fiberboard (wood-fiber boards) at least as the back wall of cabinet furniture. In this design, the material has been known to everyone for a long time.

But laminated panels appeared relatively recently, and immediately attracted attention due to their cheapness and richness of decorative solutions.

Features

Fiberboard sheets, as their name implies, are made from wood fibers. They are moisturized, thoroughly mixed with resins that glue the fibers together, and are pressed at high temperatures.

Large-format plates coming out from under the press are cut to size and sent for lamination. It consists in applying to facing panels Fiberboard decorative resin or melamine film.

The film also adheres under the press, and it can be several layers. It gives the panels not only a spectacular appearance, but also protects the surface from damage and moisture.

Note. Depending on the quality of the coating, the material may be moisture resistant and non-moisture resistant. The first can be used even for facing the working area of the kitchen, the second - only in dry rooms.

Lamination allows you to give the panels any look - they can imitate tiles, bricks, marble, wood, metal, just plain or covered with ornaments, intricate patterns or thematic patterns.

In addition to the panels themselves, manufacturers produce appropriate accessories for them - patch strips, corners, moldings, platbands and other elements with which you can decorate joints with walls and ceilings, design niches and openings, mask the seams between adjacent panels.

Types of panels based on fiberboard

Wood-fiber boards without lamination are produced by large-sized boards and are practically not used for wall decoration in residential premises. They sometimes cover the floors and paint with enamel if budget repairs are required.

But cladding panels based on fiberboard with a decorative coating are of three types:

- Typesetting - long (from 2.5 to 6 meters) panels with a width of 15-30 cm of the type of lining and with the same mounting mechanism. On one long side they are equipped with a comb, on the other - with a groove corresponding to it.

Installation is carried out by inserting the crest of one panel into the groove of the other, they are fixed with special clamps and small self-tapping screws directly to the wall or to the wooden frame.

- Tiled - have the same type of fastening as type-setting. On sale you can find plates and tiles of various sizes - 15x60 cm, 30x30 cm, 30x60 cm, 49x98 cm, 98x98 cm.

Thanks to such proportions of the sides, they can be combined with each other, creating a kind of mosaic or ornament.

For reference. Detailed instructions for installing typesetting and tiled panels have been given more than once in other materials on the site, if necessary, you can easily find them in the article “Facing MDF with wall and ceiling panels”.

- Sheet - these are panels without lock joints, about the installation methods of which we will discuss below. They also have a variety of colors and textures, shapes and sizes - from small (49x130 cm) to impressive (260x490 cm) that can completely cover a rather large wall or ceiling in the whole room.

Methods of mounting sheet panels

One of the advantages of this material is the availability of do-it-yourself installation. Moreover, depending on the state and material of the walls, it can be performed in different ways.

Glue method

It is used in cases where the surface to be coated is perfectly smooth, durable and does not require level adjustment. If this is not so, then the walls are pre-leveled with plaster, and then treated with a deep penetration primer.

Fiberboard cladding panels are first cut to size. Then they are smeared with glue suitable for the given surface and glued to the wall along a vertical line marked in advance on it.

It is very important to set the level of the first sheet so that subsequent installation does not cause difficulties.

Wall mounting on nails or screws

Working with glue is very inconvenient and risky - over time, panels can move away from the base due to poor work quality or adhesive composition. Instead, you can use a mechanical fastener for self-tapping screws or nails with decorative hats, as they remain in sight and can ruin the impression.

- If the surface being trimmed is wooden or made of wood-like materials (chipboard, SIP panels), installation is carried out directly;

- If it is made of concrete or brick, you must first very accurately mark the walls in accordance with the dimensions of the panels and drill holes in it. Wooden corks or plastic dowels are inserted into them, into which fasteners are made.

The disadvantage of this method is that the attachment points are difficult to hide. But you can do this by closing the joints between the sheets with decorative overlays or by drowning the heads of the screws in the body of the panel and sealing them with tinted putty.

Tip. Panels with a pattern for tiles or masonry are best fastened “in the seams”, and monophonic - adhering to straight lines, so that all openings can later be easier to decorate.

Crate mounting

This is the most reliable and most correct installation method. You can familiarize yourself with it by watching the training video.

The crate or frame allows you to align the walls without the use of dirty plastering, it due to its thickness provides an air heat and sound insulation layer between the wall and the panels, allows you to secretly lay communications or fix the insulation under the lining.

It is mounted from wooden blocks or plastic profiles with a step of 30-40 cm. To it, panels cladding of fiberboard are fastened by the above methods - onto screws or nails. Additionally, you can use glue.

Installation ends with the installation of accessories - platbands, plinths, corners and other elements that decorate the joints and give the lining a finished look.

Conclusion

Let's not dissemble - fiberboard panels are not the most chic material for interior decoration, it is hardly capable of creating a sense of solidity, respectability in the room. But its price compensates for these shortcomings and allows you to fairly finish the cottage, summer country house, apartment for rent.