Artificial panels for cladding and their features

Artificial facing panel for finishing buildings has become indispensable in some finishes. They can be seen when decorating only a private house, but also a high-rise building.

Artificial facing panels are quite different in composition and method of attachment. Sometimes it can be difficult to choose the right model. Today we will deal with this issue.

You will familiarize yourself with their types and application features. Also, photos and videos on this topic will be presented to your attention and you can understand this issue in more detail and make your right choice.

The content of the article

Facade systems

Artificial panels for cladding consist of a variety of insulation materials, frame, as well as facade decorative material. When mounting the supporting frame, a ventilation gap is required between the wall and it.

This helps to create the effect of a heat shield that will retain heat in the room. There are a wide variety of types of facade panels.

They may differ in installation method, size or color. The price of this material is also quite different. But they are united by one thing, this is a do-it-yourself installation.

As a result of this, you can avoid unnecessary costs.

Among them, there are such types of panels as:

- Hinged vinyl panels.

- Panels made of metal with a polymer coating.

- Thermopanels (seeLining with thermal panels: a warm facade under a brick or stone).

- Glass panels.

- Panels that mimic stone or brick.

- Porcelain and stone panels.

- Facade fiber cement systems.

Consider them in more detail: disadvantages, advantages, as well as design.

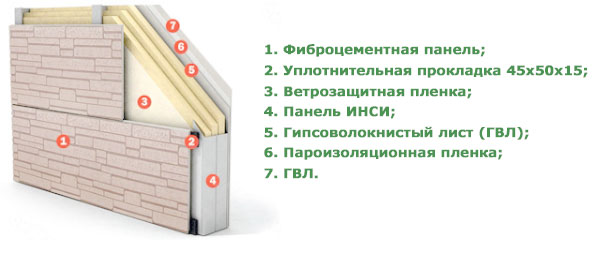

Fiber cement systems

The surface of such panels due to the inorganic film can be cleaned independently. Ninety percent of the material consists of mineral constituents and cement, while the rest is cellulose fibers. Fiber cement facades can imitate different materials.

(Thank you for the provided image repair-home.net site which also has interesting material on ventilated facades)

Among other things, the elements can be made with a coating of polyurethane, acrylic and stone dusting.

The advantages of such facade elements include:

- No corrosion and rot.

- Durability.

- High resistance to temperature fluctuations.

- High sound and heat insulation properties.

- Resistance to burnout.

The disadvantages, perhaps, include the fact that the panels must be painted after installation, they have low impact resistance and high water absorption.

Attention: Such panels can be placed on the facade of the building, but if subsequent cladding is done. Often, artificial stone cladding panels are used for this.

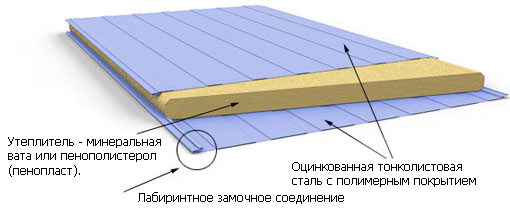

Polymer Coated Panels

The main material of such panels is galvanized steel or aluminum, which protects the polymer coating from above. The top layer can be perforated or smooth.

The thickness of such structures is about 0.56 millimeters, and the weight varies in the range of nine - ten kg / sq. M.

The following qualities can be attributed to their positive aspects:

- Moisture resistance.

- Frost resistance.

- Durability.

- Lightweight during installation.

- Incombustibility.

- No corrosion.

The panels withstand quite serious temperature changes, are resistant to shocks, and have a high noise absorption coefficient. The disadvantage of this metal is its low heat-insulating ability.

Panels repeating stone and brick

Artificial Panels facing stone usually used to decorate the entire facade or any specific parts, as well as for the basement of the building. In the manufacture of panels using resin, which has a polypropylene base.

After the mounted ventilated systems are installed, the building looks as if it is faced with stone blocks or bricks, the texture of these materials is so precisely repeated by these elements.

Their advantages include:

- Ease of installation.

- Immunity to temperature extremes and ultraviolet.

- Long service life.

Wood fiber panels

The basis of such panels are split wood fibers, which were glued under a press. The frame plays the role of a protective layer. Such boards are faced with polymeric material or veneer. The surface of such panels simulates a wood surface.

So:

- It is quite simple to saw, drill and process them.

- The main advantage of such panels is their environmental friendliness. In addition, they are distinguished by high density, ease of installation, good heat-insulating properties, good frost resistance.

- They serve about ten to fifteen years. Their disadvantage is swelling with prolonged exposure to moisture and combustibility.

- They are quite dense, so they do not crack or warp.

But they also have their drawbacks:

- First of all, it is an opportunity to nourish moisture.

- It is also a material of increased combustibility, so there may be problems with firefighters.

Attention: Recently, there are many panels of this design on the market that do not respond to moisture. Therefore, for exterior decoration, it is worth taking those that have a paraffin emulsion in their composition. Synthetic resins are also used as additives.

Hinged Vinyl Panels

Panels made on the basis of polymers are made with the addition of stabilizers, modifiers and dyes. They can have very different colors and textures (imitate the surface of a tree or be smooth). Vinyl panels typically last thirty years.

The advantages of such panels include:

- Resistance to large fluctuations in temperature.

- Do not rot, do not rust.

- They are easy enough to cut.

- In installation, repair are convenient and simple.

- Do not fade.

- Waterproof.

Strong winds can crack vinyl panels.

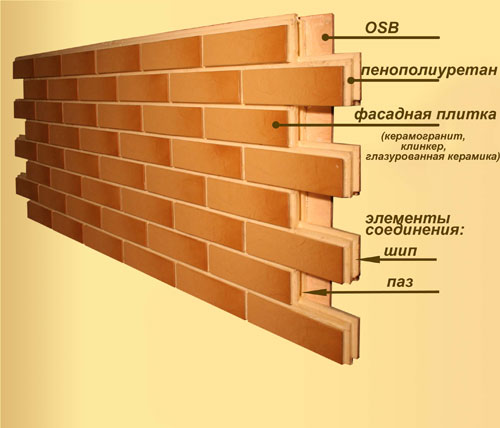

Thermopanels

These panels consist of rolled, foamed marble chips polyurethane, as well as a layer of clinker. There are a huge number of color variations. Such elements are hung vertically, while observing the crest-groove principle.

So:

- Panels for mounting on the frame have special holes.

- Thermal panels withstand many frost resistance cycles, are durable (about fifty years), are fireproof, have low thermal conductivity, do not absorb moisture, it’s easy to care for them.

- They can withstand temperature jumps ranging from -50 to +110 degrees.

- The only drawback is the toxicity of some components.

Sandwich panels mounted

The design of these panels has more than one layer. It consists of several layers of metal with insulation and vapor barrier with a thickness of about 0.051 mm. The outer layer is an alloy of magnesium, aluminum and manganese. The coating of the plates can be very different: imitate plaster, wood.

Advantages of sandwich panels:

- Good soundproofing.

- Environmental friendliness.

- Fireproof.

- Withstand severe temperature jumps.

- Low thermal conductivity.

- Do not rot.

The service life is more than thirty to thirty-five years. The disadvantages include the need for careful handling (scratches and bumps damage the panel), as well as freezing of joints at too low temperatures.

Facade porcelain tile

Such panels can be used in conditions of high shock loads and strong wind. Their fastening is carried out in different ways, but for the greatest reliability it is recommended to use a polyurethane two-component adhesive.

Ceramic and stone facade panels have a high service life (more than fifty years).

They differ:

- High impact resistance and frost resistance.

- Resistant to alkaline as well as acidic effects.

- Panels that are damaged are easy to replace.

Their disadvantages are low sound insulation and high thermal conductivity.

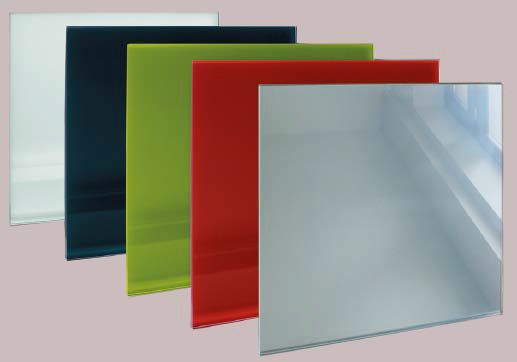

Panels made of glass

This finish is often used in office buildings and shopping centersbut do not exclude the use of glass panels in the design of houses that have an extraordinary architecture.

In such panels use different types of glasses:

- Bulletproof.

- Shockproof.

- With lamination and reinforcement.

- Hardened.

The main advantage is the ability to create an original facade, an unusual look. In addition, glass panels protect the building well from ultraviolet rays. Disadvantages - the difficulty of installation, as well as the high price.

Polyurethane foam panels

These facade panels deserve special attention. They are made of soft cellular plastic with the addition of marble chips, which are rolled into a polymer.

Such a facing material at ninety-seven percent consists of cavities that are filled with air:

- The service life of these panels is quite high, the manufacturer guarantees up to 50 years.

- Perfectly tolerating frosts, they can withstand up to 100 degrees below zero.

- Possess low heat loss means it will save heat.

- Resistant to rot and mold.

- They are not very heavy. Perfectly fasten with your own hands and this will not be difficult to do.

Attention: The disadvantages include that they do not burn but melt and at the same time emit quite toxic gas, which is harmful. And much.

Now you know what an artificial facing panel is for finishing. There is an instruction and you can start choosing, but you can do it already according to the data without any problems.