Heat-resistant paint for the furnace and its features

Thermal paint for stoves is used quite often. It does not lose color when heated and tolerates temperature extremes. This coating is also used for applying other heating devices.

Today we will understand this issue in detail and determine how much it will suit you and which one you need, because there are several types. In the video in this article, you can get additional information you need.

The content of the article

Heat resistant paints

They form a flexible and reliable shell on the surface to be painted and do not contribute to combustion.

Attention: Such paints are based on organosilicon, which includes coloring pigments, fillers and high molecular weight compounds, which contribute to a significant increase in thermal parameters.

The thermal stability is for the most part guaranteed by the coordinated connection between the base and fillers:

- The atoms of such different substances as oxygen, silicon and many organic radicals, when combined together at the base, give it excellent resistance to negative reactions from elevated temperatures;

- Organic resins favorably affect extensibility, quick drying and good adhesion to the surface;

- Aluminum ore added to the paint makes them much more heat-resistant; so much so that they can withstand temperature loads up to 600 ° C without problems.

The operation of exceptionally high-class heat-resistant materials is an integral part of fire-prevention measures.

Attention: But do not make mistakes by putting an equal sign between heat-resistant and refractory paints. “Heat-resistant” means “resistant to the stimulating effect of elevated temperatures”, and “fire-resistant” swells and forms foam when ignited.

It protects the surface and the entire structure and, in addition, produces gas that drowns the combustion process.

The main advantages of heat-resistant paints and enamels:

- They guarantee thorough and durable protection;

- Complement the elegant image;

- Wearproof and easily washed from pollution;

- They protect the area from rusting and other influences from a hostile environment;

- They have a good level of adhesion, so they avoid the appearance of cracks and do not crumble;

- Do not suffer from heat differences.

Application area

Heat-resistant paints help prevent decomposition of a large variety of materials. Among other things, they found application in the coloring of heating devices, which are available in almost every home, and in the industry.

Heat-resistant enamels and paints cover:

- Furnaces of all types and sizes (see Lining furnaces - the best solution for room design);

- Fireplaces from a wide variety of materials (see Decorative facing of fireplaces: materials and style directions);

- Heating batteries;

- Chimney flue;

- Sashes and doors at furnaces;

- Potbelly stoves and barbecues;

- Brake calipers;

- Electric motors;

- Pipelines for gas;

- Transformers

- Heating elements of production machines.

When selecting paint, pay particular attention to the following criteria:

- Upper temperature. Reference paint tolerates up to 450 ° C. Plan ahead that it is unlikely that you can manage to do just one paint for the furnace: for metal elements, it will be more accurate to choose enamels that normally respond to temperatures of 600 ° C and above.

- Anticorrosion properties. For successful painting of furnaces and boilers in bath houses and steam rooms, that is, in rooms with wet microclimate, anti-corrosion paints will be required to protect the surface from plaque. Paint with the same properties is used for street bourgeois and barbecue.

- Main substance. To avoid poisoning by emitted toxins, make your choice in favor of paints with a water base or at least based on non-toxic solvents. Refractory components will retain their laying properties even at very high temperatures.

- Fillers. If your heating element must withstand temperatures above 500 ° C, then the composition of the paint for it must necessarily be aluminum or zinc powder.

Attention: In specialized stores you can find universal thermal paint applicable to all types of surfaces. At the time of coating, it forms a thin shell through which air and moisture do not pass.

In order to avoid mistakes, the instructions should be carefully read before purchasing the paint, check the directional information with your needs, study the reviews of people who have already bought it, in addition, talk with the seller and specify which surfaces to use and under what thermal conditions it is recommended - this it can be steam, fire or dry flint, metal, ceramite or concrete. Do not miss the chance to look at the marking - it can answer many questions.

Type and labeling

Heat-resistant paints according to their boundaries of application can be divided into several classes:

- For everyday life - most often they are designed for operation at 80-100 ° C. Their basis is alkyd or acrylic. They form an integral shield enclosing the surface. Mostly they are used for painting oil and water heaters, heating radiators.

- For liquidus loading from 100 to 120 ° С epoxy based paints are made.

- Unary - for operating temperatures from 200 to 400 ° C. They differ in the presence of only one component and these are either ether-epoxy or ethyl silicate resins.

- For the temperature range 400—750˚C. For the most part, these paints are available in the form of sprays and aerosols (sometimes called smog), which are stored in spray cans.

- For industrial conditions where the heat rises above 700 ° Care based on typified silicone resin resins.

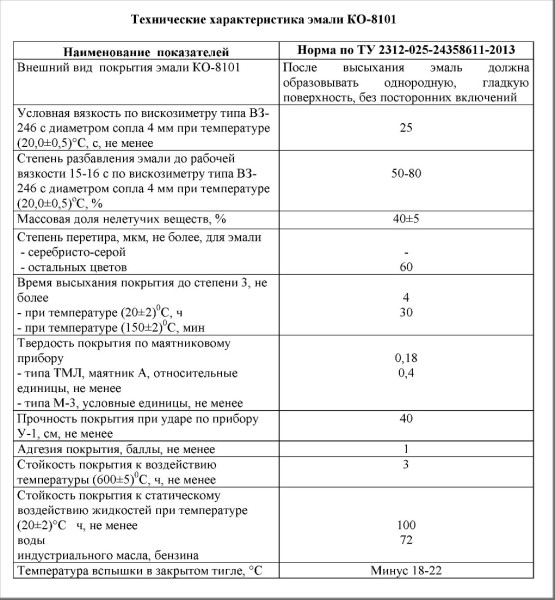

On packages with heat-resistant paints you can see the marking of letters and numbers. The abbreviation "KO" indicates that the paint is based on an organosilicon binder. If the numerical code of the product begins with 8, this indicates its thermal stability. The second figure and on to the brown production number.

Markings of heat-resistant enamels with explanations:

- KO-811 is an enamel that can be applied at low temperature. It is applied to drawing on steel, aluminum and also titanic surfaces. The resulting coating is very resistant to heat and moisture, tolerates sudden temperature changes from heat to cooling and vice versa. It is environmentally friendly, and at high temperatures it only increases the margin of safety.

- KO-813 - the range of use of this enamel is limited only to metal surfaces, but the temperature drops safe for it are slightly higher: from -60 ° C to + 500 ° C. It has a high level of corrosion resistance and is also not afraid of sudden temperature fluctuations.

- KO-814 - is absolutely calm in the range from -60 ° С to + 400 ° С. In addition, it has a distinguished hardening from salts, various petroleum products and mineral oils. Ideal if you need to paint the steam line.

- KO-8111 - is applied to metal structures whose temperatures reach + 600 ° С. Reliably protects against reactions to an aggressive environment.

How to choose between paint and enamel

Regardless of the type of paint to be used, the shielding properties are left to the discretion of the buyer. He will buy matte paint or glossy - only a matter of taste. Someone claims that the gloss looks more attractive, and someone prefers matte colors, because they add charm with rough surfaces and hide flaws from prying eyes.

Subsequently, staining with heat-resistant enamel on a pigmented surface forms a reliable impermeable shell, which serves as a protector against moisture, but can not be protected from flame.

The main differences between heat-resistant enamels and paints:

- More flexible;

- The “carapace” they create is more durable;

- They have great decorating abilities;

- Do not lose their properties even when applied in sub-zero temperatures.

Nevertheless, if there is a risk of fire and, first of all, it is necessary to prevent the spread of fire on the painted coating, it will be more correct to use heat-resistant paints.

Storage in jars or containers

Heat-resistant cans can be purchased in different formats:

- Aerosols (sprays) in spray cans of 400-500 ml (it is easy to spray);

- Liquid paint, packed in jars weighing 1 kg, in buckets of 20, 25 and 30 kg and in drums - from 40 kg.

Spray paint is sold in spray cans.

Positive aspects of spray paints:

- When applied, it is uniformly dispersed over the entire surface.

- Easy to apply even in hard to reach areas.

- It does not require dilution and therefore does not pollute the tools.

- To use the spray can not require special experience in painting work, they can be used by anyone.

- Such paints do not have a hardening process, so that the next application can be carried out in any free time.

The paint, which is stored in buckets and cans, after opening quickly hardens and is covered with a film, which is why its long storage is undesirable. However, this option is advantageous if a large area is to be painted.

What changes color

The most widespread are heat-resistant paints of silver and black tones, however, if desired, you can purchase paint of any color. Although it will come out somewhat more expensive.

Do not forget that a dark-colored oven will heat up faster than light, if that plays a role for you. A matte paint will help to better distribute heat throughout the room. But if it is important to have a radiant and bright fireplace - make a choice in favor of the red gloss - it will work perfectly!

Application Features

Heat-resistant paint does not have any specific needs for tools: its application is carried out by a conventional roller (see Paint rollers: consider in detail) or with a brush, spray gun, and everything is done with your own hands.

- If the paint is in the spray can, then in other guns there is no need at all.

Before applying the surface must be cleaned of old dirt, scale, degrease. - Before painting, the composition should be blotted out and wait a couple of minutes before air bubbles come out.

- It is recommended to apply in several passes, creating a layer on the layer, but only after the previous one has completely dried.

Heat-resistant paint for the furnace is known for good adhesion to the surface, so that when applied correctly, in accordance with all the rules, the service life should not be less than a dozen years.

Metal furnaces, steel and cast iron, have many positive qualities, but the decorative component can not be attributed to their strengths. Habitually, cast-iron stoves are painted black, and steel ones with silver. Such limited design options. significantly limit the possibilities of a homeowner who has decided to create an attractive interior. The appearance of silicon-organic paints with a wide range of colors is a real gift for those involved in the design of country houses. All the opportunities provided by new materials have not yet been revealed, but undoubtedly - the future lies with them!