We discuss the prevention of the spread of fire in the room, as well as fireproof materials for the walls

Many have heard about computer concepts such as: Firewall and Firewall, and even know the purpose of these tools for any advanced PC user. But few people know that these terms are also found in construction.

Firewall - translated from German means “Wall of Fire”, but a more precise meaning is a fire wall. Recently, such designs have become very common in the construction of industrial premises, but many people who care about the safety and security of property have begun to apply these technologies at home.

In today's article, we will analyze the design of a fire wall, as well as modern materials created for these purposes.

The content of the article

Fire barriers

One of the measures to combat the spread of fire indoors is the organization of fire barriers. They are made in the form of fire walls, gaps, zones and ceilings of non-combustible materials.

Fire walls

Fireproof wall (partition) with a minimum limit of resistance to an open flame at 2 hours 30 min, is called - fire wall. It can be made in two versions: blind and with holes. If with the first option everything is clear without words, then the second implies the presence of openings with fireproof doors or gates.

- The fire wall passes through all the elements of the building, and its base rests on the foundation.

- In manufacturing enterprises, such structures are used to separate administrative, residential or warehouse buildings from manufacturing sectors.

- They are also used to divide large industrial and storage facilities into parts, and to reduce the fire gap between individual buildings.

Fire walls are divided into roof, exterior, interior and free standing:

- Internal walls divide the building into separate parts;

- External fire walls coincide with load-bearing walls, and prevent the spread of fire to adjacent structures and buildings;

- Both of these types of walls can be both longitudinal and transverse. The placement is calculated relative to the location of the longitudinal axis of the building.

- Fire wall between the compartments on the roof, fenders combustible structural elements.

- To protect against the radiant energy of two nearby buildings, use free-standing fire walls. Such structures are needed if the distance between adjacent buildings does not meet the requirements of fire breaks.

Firewall walls are constructed so that their plane cuts through coatings, ceilings, lighting, and any other protruding structures above the roof. Towering fire walls should be 60 cm above the roof of combustible materials, and 30 cm above the fire-resistant roof.

For gates, doors and other openings in firewall walls, there are also requirements. The minimum fire resistance of these elements is 1.5 hours.

The number of fire walls is determined at the stage of engineering calculations even before the construction of the building begins. It depends on the fire hazard of future production, the degree of fire resistance of the material used, the total area of the building, as well as its number of storeys.

Fire zones

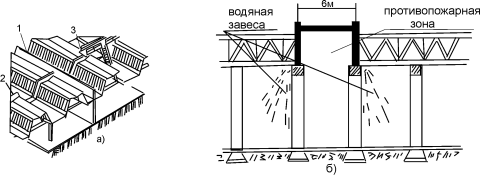

If during the construction of a one-story industrial building, due to the technological features of production, it is not possible to place firewall walls, then the construction of the building provides for the placement of fire zones.

- They are buffer strips made of a fireproof coating that rest on fireproof supports. Fire zones divide combustible coatings, walls and ceilings into compartments, the width of which should be at least 6 meters.

- Fire zones are divided into longitudinal and transverse. The sides of the buffer strips should be 70 cm above the combustible or fire-resistant roof (this value is minimal).

- In the diagram of the device of the fire zone, which is given above, you can see that on two sides, at the edges of the strip, special devices are installed - dealers. With their help, a water curtain is created that prevents the spread of fire.

The deluge system is equipped with automation that responds to threshold values of smoke, temperature and its dynamic changes, after which water with fire extinguishing additives is supplied to the sprayers.

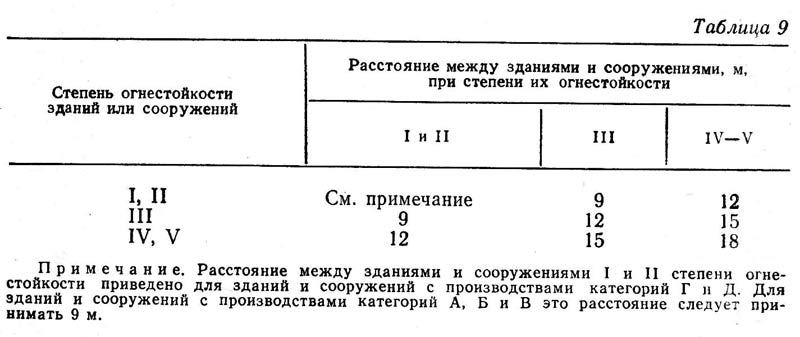

Fire breaks

The distance between two buildings, structures or warehouses in the production and residential areas is called a fire gap. It is determined based on the degree of fire resistance of the most fire hazardous facility, which is divided into categories. Data on the ratio of these values is presented in the picture below.

You can learn more about the fire hazard categories of buildings by studying the federal law of July 22, 2008 N 123-ФЗ (as amended on July 13, 2015) “Technical Regulations on Fire Safety Requirements”. Also, article 87 of this law contains information by which it is possible to determine the fire resistance limit of a fire wall.

Non-combustible materials for interior decoration

All data presented in the first part of the article can be attributed to purely informational. So to speak - for general development. This is because for most ordinary people, they are not applicable in practice, as they require professional skills and knowledge.

But what if the construction of the house is nearing its end, or even completed, but the firewall was not included in the structure? What can we build in our own house with our own hands to protect ourselves, loved ones and property from fire?

For these purposes, modern industry has launched the production of non-combustible finishing materials, which we will consider further.

Material classification

According to the combustibility class, all finishing materials are divided into three types:

- Incombustible - These are materials that do not support open flames. They cannot be ignited by fire, sparks, electric current, high temperature or chemical reactions. According to SNIP 21-01-97, they all belong to the category of NG, which is indicated by the corresponding marking in the name of the material.

- Materials not capable of self-combustionbut those who maintain an open flame are called fire-resistant.

- All other materials are combustible..

Whereas before, fire shields were mainly installed to fight the flame, modern materials have good aesthetic properties, which makes their use much wider and more popular.

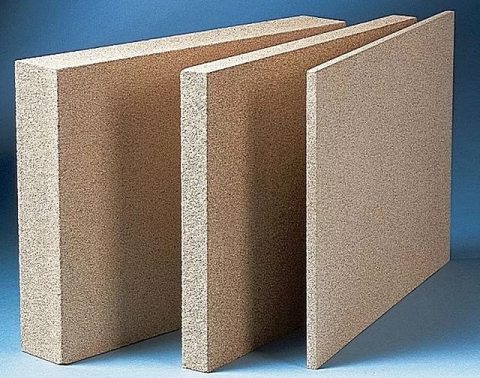

SCR panels

This material is a dense sheet with a size of 1200 * 2500 mm, including calcium silicate filler. This material, with its lightness, has decent strength. It is non-toxic, and suitable for use in living quarters.

Most SKL models already have a finished look on the front side, and need only the right installation, but there are also options that require further decoration. The installation instructions for these panels are no different from the installation of drywall, and you will need the same tools.

- SCR has a smooth surface, which is saturated with antiseptic and hydrophobic solutions, so that the panels are ready to sticker wallpapers, tiles and plasters without prior treatment.

- Silicate-calcium sheets have a huge scope. They are equally well suited for finishing walls, floors, ceilings, facades, as well as for the construction of formwork and the organization of protective screens on the roof.

- This material is indispensable for lining saunas, baths (see.DIY bath decoration: stages of finishing work), high-temperature premises in production, decoration of fireplaces and stoves.

- Additional advantages of SCR include high elasticity and sound insulation, due to which it is often used in the decoration of night clubs, bars and recording studios.

Advice! By installing such a panel on the wall, you additionally solve many problems: protect yourself from moisture, precipitation and temperature changes, improve heat and sound insulation.

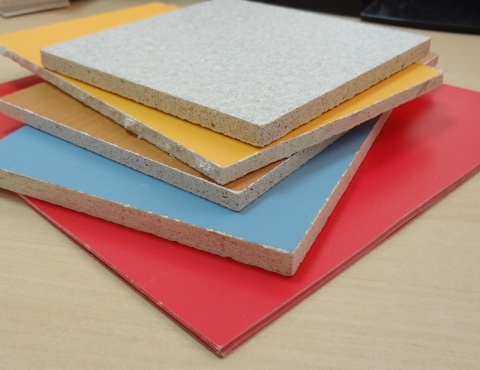

LSU panels

Glass-magnesite sheet is a material based on magnesium oxide and special additives reinforced with fiberglass on both sides.

Like the previous material, LSU can be used as a finish and rough finish for subsequent work. The photo shows panels with different colors and textured designs. The average price per square meter of this material is 300-400 rubles, for a sheet 12 mm thick.

The characteristics of this material are similar to calcium silicate sheets, but have higher strength and stiffness. They are mainly used in places with a high kinetic load (roofing, floors, etc.). Also, LSUs are excellent for finishing ventilated facades, sandwich panels and reinforcing foam concrete.

Refractory Drywall

If you are looking for a more affordable solution, then pay attention to drywall treated with flame retardants, which is labeled as GKLO or GKLVO. The surface of this material is painted pink, which helps to accurately find the desired sheet from the total mass.

Technical specifications for fire safety, this material is much lower than that of the above analogs (the refractory sheet of drywall is able to withstand the effects of an open flame for only 20 minutes), but the favorable price makes this material more attractive to most people who equip their homes.

Attention! Like other drywall models, GKLO needs subsequent finishing.

Wallpaper from refractory materials

Even among materials such as wallpaper, representatives wound up with excellent fire safety performance (seeFire wallpaper: technology and application).

Non-combustible wallpaper is made of fiberglass. They have a pronounced texture, and have a decorative pattern that gives them an aesthetic appearance. The surface of this material is excellent for painting, which allows you to create an original interior of the room, not limited to the colors presented by the manufacturer.

Fiberglass Wallpaper in fact, they are a full-fledged refractory coating capable of preventing the ignition of bearing elements.The thing is that for their production, quartz sand is used as the main material, from which the fibrous structure is isolated. This mineral is famous for its strength and resistance to high temperatures.

This wallpaper is immune to mechanical damage and deformation, and due to its low absorption capacity, they easily tolerate moisture, and are even suitable for regular washing with soap and water.

Non-combustible fabric

Today, as in antiquity, many designers prefer to decorate the walls with fabric, creating unique combinations of textures and materials. This fact could not go unnoticed by the ubiquitous "industrialists-capitalists." As a result, the light saw a new material that is not inferior in beauty to classical fabrics, but at the same time is made in such a way that it easily resists fire and high temperatures.

The basis of such a fabric is made up of polyester substances, due to which the structure and density of the fabric does not change during the operation of the product. In the production process, a fabric base is formed from them, which is then impregnated with flame retardants (substances that give refractory properties). Similar technologies are used in the manufacture of clothing for firefighters.

These fabrics are used not only for interior decoration of premises, but are also widely used in the automotive industry, in the decoration of automobile interiors.

Mineral insulation

Mineral wool is a non-combustible material, but, unfortunately, it does not provide any protection for the exterior decoration of the room. However, the use of this material for fire fighting purposes is justified. With it, it is possible to protect the floors and supporting structures of the building, thereby preventing premature destruction of the structure during a fire.

Also, do not forget that mineral wool is an excellent heat and sound insulator. The market has many of its modifications made from various raw materials. To understand the full variety of these materials, you can study the relevant articles on our website. We also recommend that you pay attention to the video in this article.

Addition

Of course, to completely protect your home from fire, it is not enough to use only wall decoration. In rooms where the likelihood of fire is especially high, it is necessary to make high fire safety requirements for floor coverings. Of course, it is not always possible to create an attractive appearance of the room from the same materials, but if you faced the task of constructing such a room, then some things should be done, in the name of security.

In some rooms it is recommended to install automatic fire extinguishing systems, or fire detectors. Such alarms will allow you to detect a sharp increase in temperature or a high concentration of smoke in time. There are models that can detect the occurrence of an open flame, such devices are called flame detectors. They scan the allocated space in the ultraviolet, or infrared range (depending on the model of the sensor).

Remember that the material used determines the property of a fire wall, such as fire resistance. Therefore, if you still decide to equip your house with non-combustible materials in order to protect yourself from accidental fires, then take some time to study these characteristics. It will come in handy even if you hire trained workers to carry out these tasks. You can avoid cheating on the part of the contractor, and not acquire completely unnecessary material.

If we talk about non-combustible materials for walls, then a heater from such a material should be vapor insulated. If the insulation is made of combustible material, then the voids between the insulation sheets must be filled with slow-burning materials.