Brick cladding - process technology

Among the many exterior decoration materials, brick, by its popularity, still occupies one of the leading places. It is preferred not only by conservatives faithful to traditions, but also by people who strive to make their home durable, reliable, solid and warm. A brick cladding of buildings is suitable for this as well as possible.

The content of the article

Production technology

If such an idea home decoration arises even at the stage of its design, architects immediately make all the necessary calculations, taking into account the load from the brick cladding on the foundation and other supporting structures, its thickness and masonry method.

If it is planned to brick the old house for its external renovation, insulation and protection from the effects of atmospheric phenomena, the building must be prepared for such a restoration. And the cladding process itself must be conducted differently than when decorating a new house during its construction.

Preparatory work

Brick is heavy material. Facing a one-story building with an area of about 100 m2 gives a load on the foundation equal to forty tons. It is clear that if the base is not designed for such an additional weight, it may not withstand.

In addition, the thickness of the walls with this finish increases by about 20 cm, which means that the width of the foundation and the removal of the eaves of the roof must correspond to the new parameters of the building. What if this is not so?

So:

- First of all, the bearing capacity of the existing foundation is calculated taking into account the depth of its foundation and the type of soil under it.

- If the facing of a residential building with a brick does not create a limit or exceeding the calculated load, it is necessary to measure the ledge of the foundation on which the brick will rest. The ledge of the cladding beyond its edge is allowed no more than 1/3 of its thickness.

Note! When determining the required width of the ledge of the foundation, it is necessary to take into account the unevenness of the walls and the need to leave a ventilation gap of 2-5 cm between them and the masonry. And if insulation is required, then the thickness of the heat-insulating material.

- If the width of the base is insufficient, it is increased with steel corners fixed with anchor bolts. Or close to the main, they arrange an additional strip foundation of concrete blocks or reinforced concrete.

- It is more difficult to extend the eaves overhang without reconstruction of the roof, but it is necessary to do this, otherwise the masonry that is constantly wetted by the rain and snow will quickly collapse.

Temporary and labor costs for preparatory work, as well as their price, can be very high. If you think that it is economically unprofitable for you, but do not want to give up your idea, you can go the other way.

Facing buildings under brick, clinker tiles or thermal panels are visually completely indistinguishable from real brickwork, but it does not require strengthening the foundation and slightly thickens the walls.

How to perform the facing

There are no fundamental differences in how brick cladding of monolithic buildings is made, wooden or frame. But some nuances and differences are still present. First of all, they relate to insulation of load-bearing walls and fastening of facing masonry to them.

But let's start with the general processes, namely the preparation of materials and tools:

- The amount of face brick required is calculated based on the area of the walls minus the openings, but 10-15% is added to it for battle, trimming and defective products.

- For the masonry mortar, cement, lime and sand in the proportions of 1: 1: 4, and also clean water, will be needed.

- You will also need fasteners for the installation of insulation and ligament lining with load-bearing walls.

- Necessary tools: trowel, building level, tape measure, fishing line, hammer, hammer drill.

For reference. The list of materials and tools may vary depending on the material of the walls.

Laying is carried out with an offset in half a brick. It is very important to lay out the first row evenly, the correctness of further masonry depends on this. To do this, first, angles are laid out on a dry one, a fishing line is stretched between them, and its position is checked by level.

But before starting the cladding, it is necessary to insulate the walls with your own hands. The choice of heat-insulating material and the method of its fastening depends on what the house is built of.

So:

- Wooden walls are first cleaned of rot and mold, impregnated with an antiseptic solution, and then a battens of battens are attached to them. Their thickness should be equal to the thickness of the insulation, and the distance between the rails - its width minus 1-2 cm.

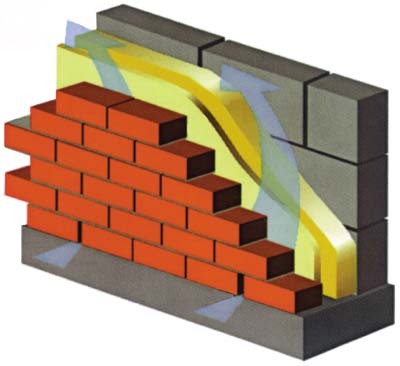

Insulation (mineral wool) is laid opposite between the battens of the crate, a vapor-permeable film is stretched over it, which is attached to the crate with brackets. Then the insulation and vapor barrier are additionally attached to the walls with dowels with a wide hat.

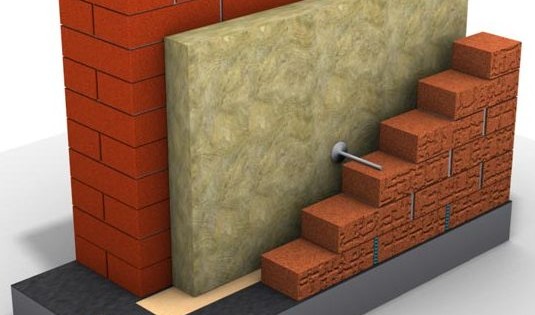

- Insulation is fixed to stone, brick or concrete walls with plate dowels with preliminary drilling of holes for them. Or, if the surface is flat, thermal insulation can be glued to the walls with a special adhesive solution. Before installing the insulation, all cracks and cracks should be repaired.

So that moisture does not accumulate on the insulation and the inner surface of the cladding, the instruction requires a ventilation gap between them a few centimeters wide. As well as the device of the so-called vents in the lower and upper (under-cornice) rows of masonry.

Products are made in vertical seams between bricks, without filling them with mortar. To do this, every 3-4 bricks, a wooden lath with a thickness of about 1 cm (joint thickness) is temporarily inserted into the gap between them.

Further brick cladding buildings are conducted as usual, but it must be fastened to the main wall. To do this, use stainless steel anchor bolts - for monolithic and brick walls, or long nails (pins) made of galvanized steel - for wooden walls.

Anchor bolts are installed in pre-drilled holes opposite the seam of the brickwork and partially driven in, so that about 8 cm of the bolt are fixed in the solution. The pins are simply hammered into the wooden walls.

To make the masonry beautiful, neat and reliable, observe the following rules:

- Before laying, briefly place bricks in water to wash dust off and soak in moisture. Dry stone draws moisture from the solution, which reduces the quality of adhesion.

- Do not work in the rain or at freezing temperatures.

- When preparing the solution, sift the sand to exclude the presence of large particles, plant debris and earth in it.

- Apply the solution evenly, observing the same thickness of the joints (1-1.2 cm) and controlling the level of each row.

- If the solution has got on the front side of the masonry, remove it immediately, not allowing it to harden.

Before you begin this work, we recommend that you also watch a video to better understand the technology of facing.

Brick imitation

Today, there are many finishing materials that imitate brickwork very realistically. With their help, you can give the house the desired look, spending on it much less time and money. What kind of materials are these?

So:

- Brick tile. It is made from the same raw materials as clinker brick, therefore it has all its properties and characteristics.

- Fake diamond. It is made from a mixture of cement with various fillers and dyes. In addition to bricks, it can imitate various breeds of natural stone.

- Thermal panels. These are panels made of foamed polyurethane, which in themselves are an excellent insulation. Their front part is decorated with stone chips or clinker tiles.

- Siding. Vinyl, metal or fiber cement - any of its types can imitate not only Deoevo, but also brickwork.

Conclusion

The desire to have not only a reliable and durable, but also a beautiful home is inherent in every person. And everyone chooses the type of exterior that matches his taste and wallet.

Brick cladding of reinforced concrete buildings or wooden structures is not the most budgetary option, but it clearly indicates the solidity and solidity of their owners, which is why it is very popular even despite the emergence of new technological materials.

Brick cladding, in addition to the decorative role, also plays a magnificent role of insulation. And very good. Yes, and deciding the design of the external brick cladding, you can play with color, the benefit of brick colors for cladding is now enough and it is not necessary to adjust to the standard color, but you can choose it taking into account the current or future roof, or using other criteria.