Do-it-yourself door trim with MDF panels

The decoration of MDF doors with panels is gaining popularity and it is crowding out from the construction market the finishing materials recognized for years from leather and laminated particle boards. What does the abbreviation MDF and its full name mean?

Tracing paper from English - Medium Density Fiberboard translated as “wood microfiber” or Melko - Dispersion Fraction and an abbreviated form in Russian, meaning the name of the new material and panels to which these three letters are added so that they can not be confused with other products.

The content of the article

Door Finishing Procedure

The practicality of the appearance of the coating of the MDF panel and the beautiful appearance put them on a par with elite finishing materials.

So:

- The popular finish of MDF door panels harmoniously combines a presentable appearance, high resistance to mechanical damage and the absence of properties that interact with the environment.

- The best sound and heat insulation of a room is determined by the thickness of the facing panel, instructions can be obtained directly in the store, as well as the price of these materials.

- Any work can be done with your own hands and your own tools, but it is better to entrust something to specialists with the necessary equipment.

- Manufacturers have brought opportunities to have beautiful entrance doors without replacing them and provide consumers with a wide selection of products in the construction market.

- Installing MDF panels on doors with standard sizes does not take much time. When aboutmetal door trims The apartment often uses paint and wooden dies.

Now there is an opportunity to get hold of steel doors with MDF finish and even on both sides.

Installation is carried out in several stages:

- Pretreatment of metal surfaces with corrosion agents that protect the metal from moisture and condensate.

- Marking and drilling holes for the doorknob, lock and other hardware, if it is present on the doors.

Attention: It is recommended to replace old door locks with modern and more advanced ones.

- They are fastened with special screws, the length of which does not allow to damage the panel on the other hand.

- Fastened, installation of fittings and locks.

Ready-made standard steel doors with MDF panels have a basic size of 2050 x 860/960 mm. The efficiency of installing MDF panels on the door with an external steel sheet thickness of 2 mm is enhanced by the presence of two reliable locks and a cut-in eye with an almost circular view (120 ° viewing angle).

Of particular interest are products lined with plastic, which has high strength and is not scratched. Exterior finish by other manufacturers is carried out by lining panels with veneer of valuable species with a panel milled from solid wood and varnished.

Finishing work of openings and slopes

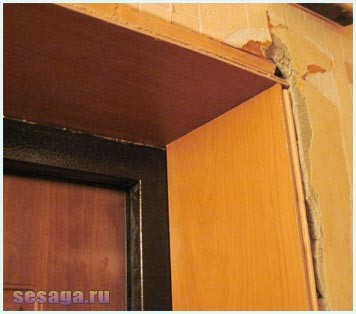

After completing installation work and installing doors, disposing of old slopes, a not-so-attractive picture opens up to the eye, which needs to be fixed. Door Slope Finish It is a laborious, albeit necessary process.

A guarantee of a beautiful view is a quality finish.

Firms that install doors usually fill the space between the installed door frame and the doorway with foam, and then do the finishing work for an additional fee, and you can do it yourself.

Tools

Plastering is a complex and lengthy process that requires certain skills. Finishing the doorways greatly simplifies the work and reduces the cost of time, effort and emotions.

Independent work implies the presence of the necessary tool, improvised things:

- MDF panels;

- Platband,

- Decorative elements - a rail and a folding corner of all in the amount of three pieces;

- Liquid nails, dowels, self-tapping screws and preparatory work. Close up cracks and holes, level the surface surrounding the opening, level with wood blocks those places where there is no possibility of quick leveling with a solution.

Finish

After preparing the tool and material, you can begin to work:

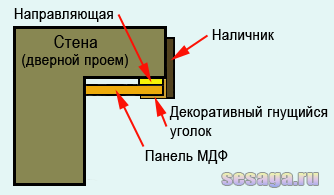

- On the prepared opening guide strips of wood are packed. The thickness of the strips (rails) is 10 mm and the width is not less than 30 mm, along the perimeter their length is at least 9 meters.

- Their fastening is made from top to bottom and is controlled by the level where the deviation is observed, a piece of wood is laid there or the plank is attracted to the wall. The upper trims are strictly fixed at the corners of the door frame.

Before installing the guide strip and fitting the MDF panel, it is necessary to take into account the thickness of the decorative corner so that the platband fits snugly against the wall.

- To obtain the desired result, it is necessary to lean against the casing and determine the gap, perhaps the thickness of the corner does not need to be taken into account in this particular case and it does not have to be cut and adjusted flush with the wall, but it will be enough to glue it.

- A decorative corner is necessary for fixing the outer and inner sides of the panels, and it is almost impossible to get the perfect cut at home.

- After fitting and installing the upper slope, it is necessary to attach it to the upper bar with small studs or short self-tapping screws, their heads will then have to be hidden

- When marking the guide rails for side slopes, this difference is taken into account and the thickness of the rails is adjusted.

- We measure the height and width of the future slope on the left side.

- In height, one measurement is made from the upper slope of the outer corner to the floor. The width measures the distance from the metal frame to the outer corners of the upper and lower parts of the doorway.

Finishing the slopes of the front door MDF panels approaches the crucial moment in order to correctly and immediately cut off the upper corner at the left side panel. A template is indispensable here. - It is preferable to prepare a template from a thick sheet of paper (cardboard), which slides along the guides up. A corner is marked and the excess is cut with a very sharp knife to get a straight line.

The operation can be repeated several times, until the template is fully and snug. - Finishing the door slopes of MDF video clearly demonstrates that all doors have a left shift relative to the doorway or to the right, no matter how they are aligned, and the opening angles therefore differ.

- The slope is fixed from the side of the frame with glue or small carnations, which can then be covered with a decorative strip, the outer side is fixed with screws.

To fit the panel snugly against the door frame, adjust the end angle between them.

- The final finishing of the slopes of the front door with MDF panels includes the filling of the gaps between the slopes with putty.

It remains to be creative in designing the outer part of the slopes:

- The foldable corners adhere and the protruding parts are carefully cut to create a straight line with the wall.

- Platbands are attached. It is recommended to start with the installation of the side and end with the top. Even a shift of 1 mm to the side or a mounting error in height leads to big problems with the upper platband.

Finishing the door slopes of MDF panels can be considered complete if it was possible to nullify the gaps, adjust all the corners and cut lines, and they processed turned out to be beautiful and even.