Interior decoration of the house from vulture panels and its features

The modern construction market offers many finishing materials that have occupied a worthy niche for the design of the premises. Decorating houses from vulture panels can currently be performed using any modern material.

The content of the article

- What are sip panels and their properties

- Construction Finish Options

- Decorative plaster in the decoration of the building from sip panels

- Surface preparation for applying decorative plaster

- The process of applying decorative plaster to the plastered surface

- Plastic lining in the decoration of houses from sip panels

- Ceramic tile for finishing sip panels

- Installation of ceramic tiles on the surface of the sip panels

What are sip panels and their properties

In order to disassemble what material will be made home decoration from sip, you must initially know what kind of material it is and what it consists of.

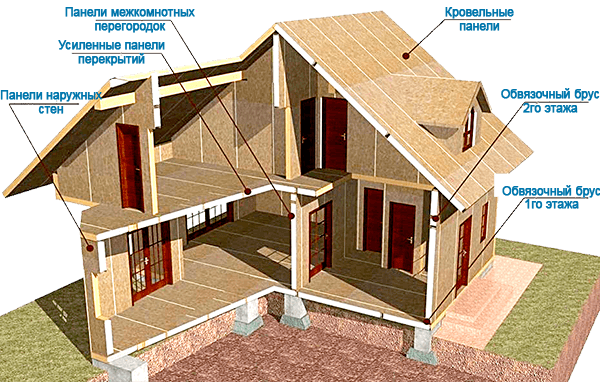

Sip panels are a fairly strong building material, which consists of three layers:

- The first is sheets of thick OSB.

- The second is foam or polyurethane foam.

- The third is a sheet of thick OSB.

Features and specifications:

- This material is considered environmentally friendly and is able to withstand a variety of loads. Not only one-story buildings, but also two-story buildings are erected from it.

- Because the polystyrene lining is a sheet of OSB, we can say: the surface of the material is flat and does not require additional alignment. Also, houses of this type are not insulated, since polystyrene is a dense insulation and insulator.

Tip. If it is planned to spend time in the house from sip panels in the cold season, then it is worth taking care of additional insulation, which is carried out outside with the help of similar material.

Construction Finish Options

These designs have virtually no restrictions on the choice of finishing material.

How is the interior decoration of houses made of sip panels, what material is suitable:

- Decorative plaster.

- Plastic clapboard.

- Ceramic tiles.

- Wooden clapboard.

- Block house.

- Decorative panels.

- Natural and artificial stone and much more.

Note. All materials are practical and durable and available for easy installation.

Decorative plaster in the decoration of the building from sip panels

Decorative plaster has been used for interior decoration for many years. Working with her is pretty simple.

Room decoration with its help can be limited only by the imagination of the designer. It has a large selection of colors and shades.

There are also interspersed threads, crumbs of natural stone, fabric tows and much more.

Plaster has:

- Moisture resistant.

- Vapor permeability.

- Practicality.

- Longevity.

- Exquisite appearance.

- Frost resistance.

- Wear resistance.

Note. It does not fade from the rays of the sun and does not deform from temperature extremes.

To date, there are various types of this material that are widely used in both external and internal works:

- Acrylic plaster (polymer) - has excellent properties and characteristics, has almost always a glossy surface.

- Mineral, which consists of sand and lime and does not cause any harm to human health, use it for internal work, as the surface is matte and quickly gets wet.

- Silicone plaster and silicate, which in their properties are quite similar and in most cases are used for outdoor work.

Finishing the vulture panels with decorative plaster should be carried out on the prepared surface.

Surface preparation for applying decorative plaster

Such a plaster can not be applied to a normal concrete or wooden surface, since over time it can simply move away from the surface and begin to deform. The preparatory work consists in plastering such a surface, if such actions have not yet been carried out on it.

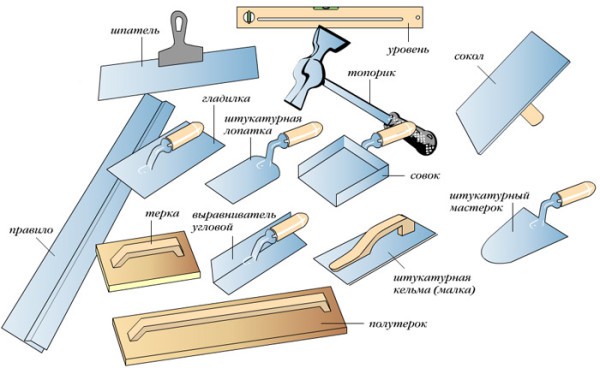

For this process you will need:

- Start and finish plasters.

- Capacity for mixing their solution.

- Construction mixer.

- Level.

- Special mesh for plaster.

- Conventional push pins or a construction stapler.

- Sandpaper.

Stages of work:

- The whole process is easy and do it yourself very quickly.

- Initially, a grid for plastering the surface is attached to the surface of OSB sheets around the entire perimeter of the room using a construction stapler or buttons.

- After this, the mortar of the starting plaster is mixed and applied to the surface in small layers. Before the next application, the previous one should dry.

Then the starting layer is treated with sandpaper. - Finishing is applied to the starting plaster. All actions are performed similarly. Using the building level, the application of plaster is checked during the work process.

Note. Only after completing all work using conventional plaster can you start using decorative.

The process of applying decorative plaster to the plastered surface

Decorative plaster is sold only in a dry, loose state, and in order to give it the desired consistency on the packaging there is a special instruction. Strictly water is poured over it into the container and powder is gradually poured into it, while stirring the composition.

Tip.

To speed up this process of preparing the mortar, you need to use a construction mixer, with which the mixture will be a homogeneous mass. Also, do not immediately knead a large amount of mortar, since the properties of the plaster will be lost over time.

Features of the application of the material:

- To apply decorative plaster, you will need two spatulas (1 - large, 2 - small), sandpaper (in extreme cases, if there are too visible defects on the surface after applying the product).

- The level in such works can not be used, since the tool is applied with thin, almost translucent layers. A large spatula of the solution is applied to the surface, and a small one is auxiliary and serves to remove excess solution from the large spatula.

Tip.

When choosing decorative plaster, it is worth clarifying what kind of shade it will have after drying. In some cases, its color may vary depending on the number of layers applied.

Plastic lining in the decoration of houses from sip panels

Plastic has been used in any finishing work for a long time and has gained its popularity due to its quality and properties.

Is he:

- Moisture-resistant and resistant to temperature extremes, which makes it possible to use it in rooms with high humidity.

- Practical and does not absorb any kind of pollution (its surface can be cleaned with a normal wet rag).

- Durable and reliable, as it does not deform under heavy loads;

- It does not fade in direct sunlight, which makes its appearance unchanged for a long time.

Material Features:

- Plastic lining is produced in stripes, which have special locks at their ends. With their help, and fastening all the elements of the decoration.

Plastic has a very low weight, and for its installation will not need to reinforce the surface. - It is worth considering that the price of such finishing material compared with others, it is very low, which makes it even more in demand.

- As a rule, plastic is mounted on a special crate. But in decorating houses from sip panels, such actions began to be carried out quite rarely.

They fix the material directly on the surface of the OSB sheets, which makes it possible to save space and time.

Tip. Such actions do not need to be done, since the OSB sheet is made of wood (breathable material) and it is capable of passing air. This is not the case with plastic lining.

If it adheres tightly to such a surface, then over time a variety of fungal diseases can begin to form on it.

It is for this reason that it is best to build a wooden crate on the surface for mounting small plastic panels.

You can freely attach material to it. The video shows the process of working with a plastic lining.

Tip. If the interior decoration of the sip house is carried out with a plastic lining, then for its greater strength it is worth using a construction stapler on the top and bottom of the material, the brackets of which will firmly fix the lining on the crate.

Ceramic tile for finishing sip panels

The interior decoration of sip houses can be done with ceramic tiles. In most cases, it is used as a floor covering, for the design of the kitchen and sanitary zones.

Tile:

- Practical.

- Moisture resistant.

- Frost resistant.

- Does not absorb dirt.

- Easy to install.

These are not all the advantages of such a finishing material:

- Ceramics are durable and reliable. It is capable of withstanding significant loads.

- Tiles can have a different design, size and surface (glossy or matte, convex or concave, porous or embossed). You need to work with it carefully, since the tile itself is considered a fragile material.

- Finishing sip panels with tiles will last a very long time, since the material does not fade in the sun and its average life is at least 20-30 years. It all depends on the quality of the ceramic tiles and on how much the house shrinks.

The last indicator is required to know only if the structure is made of brick or other stone. Sip-panel houses practically do not shrink.

Installation of ceramic tiles on the surface of the sip panels

The interior decoration of a sip house using ceramic tiles begins with preparatory work on the surface. Since the OSB sheets are even, it remains only to prime them and allow the product to absorb well.

For installation it is used:

- Special glue.

- Putty knife.

- Cruciform lighthouses.

- Level.

- Decorative putty.

Tip. In such works, it is not worth using cement mortar instead of special glue, since a strong bond with cement will not be provided on the surface of the OSB sheets.

Glue is applied on both surfaces:

- OSB sheet.

- The back side of the tile.

These actions are carried out using a spatula. An even distance is provided by cruciform beacons.

At the end of the work, the seams are processed with decorative putty of the desired shade.