Soundproofing materials for walls and ceilings: types, features, application

In our high-tech time, the noise made by people, machinery, equipment, is a constant companion of life. He accompanies us at home, on the street, in the workplace, in public places. Unnoticed by a person, noise can lead to nervous breakdowns, stress, irritability, and sleep problems.

It is especially important to minimize its effect on the human body in apartments and private houses, where everyone should feel relaxed and comfortable - especially after a busy day. To create comfortable living conditions, soundproofing materials for walls and ceilings are used.

The content of the article

Noise, its types, regulatory indicators

Design, construction, operation of buildings is regulated by SP 51.13330.2011 “Protection against noise”. However, often, especially in old houses, the level of sound insulation leaves much to be desired.

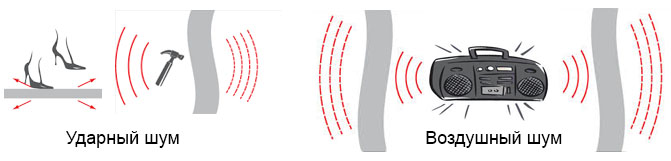

Depending on the nature, noise is divided into two types:

- Air. It spreads through the air. This may be the noise from passing vehicles, working engineering systems, people talking, loud music. To combat such noise, materials with an airborne sound insulation index Rw.

- Shock. Appears from direct effects on walls and floors - for example, with building tools, falling objects or heels. Insulation with index L can cope with such noise.nw.

Important! It is worth noting that the higher the Rw index, the better the noise insulation characteristics of the floor, however, the situation with the impact noise insulation index is exactly the opposite. The smaller it is, the better the soundproofing of the floor.

In order to understand what sounds of various origins are, we give a few examples.

| View | DB level |

| Rustle of leaves, whisper | 15-20 |

| One meter conversation | 40-45 |

| Typewriter | 50 |

| Screams, laughter | 75-80 |

| Motorcycle sound | 85 |

| Thunder, chainsaw | 100 |

According to SanPiN 2.1.2.2645-10, the maximum noise levels in residential premises: from 23-00 to 7-00 - 45 dB, from 7-00 to 23-00 - 55 dB.

After you have managed to determine what you need to protect your peace from, you need to understand how and how sound insulation of the walls and ceiling in the apartment will be carried out.

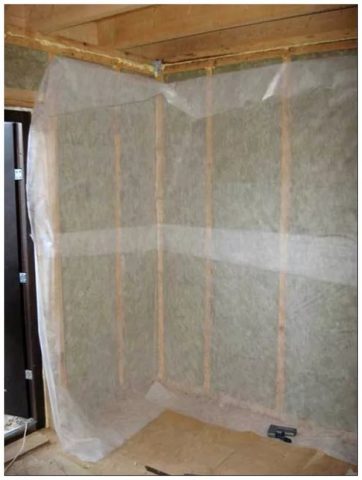

The ideal option is to soundproof all surfaces in the room (as seen in the photo).

Some required indices of airborne sound insulation, and given levels of impact noise in sound transmission, from top to bottom.

| Design name | RwdB | LnwdB |

| Overlapping between the rooms of apartments | 52 | 60 |

| Overlapping between rooms in the apartment on two levels | 45 | 63 |

| Walls and partitions between apartments | 52 | – |

| Partitions without doors between rooms, between the kitchen and the room in the apartment | 43 | – |

| Partitions between the bathroom and the room | 47 | – |

| Entrance doors of apartments | 32 | – |

Indices of airborne sound insulation of individual materials.

| Material | Thickness mm | Insulation Index, RwdB |

| “ZIPS” | 40 | 10 |

| “ZIPS” | 130 | 20 |

| “Isotex” | 12 | 23 |

| “Tecsaund” | 3,7 | 25 |

| “Isoplaat” | 10 | 23 |

| “Isoplaat” | 25 | 26 |

| “EcoZvukoIzol” | 13 | 38 |

| “Tihof” | 12 | 10 |

| “Acoustic Butts” | 50 | 9 |

Impact noise reduction indices for some materials.

| Material | Thickness mm | Impact Noise Reduction Index, dB |

| “IPOCORK“ | 2 | 18 |

| Fiberboard | 5,5 | 18 |

| Foamed polyethylene foam (density 30-40 kg / m3) | 5-10 | 18-22 |

| Eps | 20 | 21 |

| “Tekhnoelast ACOUSTIC” | 2,5-4,8 | 23-27 |

| Super Power | 6 | 27 |

| Glass wool (density 60-80 kg / m3) | 20-50 | 36-37 |

| Stone wool (density 100-125 kg / m3) | 25-50 | 36-39 |

The required reduction in the level of impact noise is determined on the basis of the given indicator of floor slabs and the required index for sanitary standards.

Soundproofing Materials

Consider the materials and structures used to isolate rooms from exposure to sound waves.

- Foam rubber

- Bung

- Quartz sand multilayer corrugated board

- Stone wool

- Glass wool

- Foamed polyethylene

Types of insulation

There are many brands of soundproofing materials on the market. Their task is to provide sound absorption or sound insulation. The purpose of soundproofing materials is to prevent the penetration of shock and air sound waves. Sound-absorbing structures are used to absorb and disperse waves.

To evaluate this ability of the material, a sound absorption coefficient αw is used. This coefficient is in the range from 0 to 1. The closer it is to unity, the better the sound absorption of the material. Fibrous, porous materials do a good job of this.

The most effective sound insulation of walls and ceiling in an apartment, combining both directions.

When choosing a material and design, several points should be taken into account:

- Dimensions of the room where the insulation will be installed.

- Type of room. Factors such as humidity, temperature fluctuations should be considered.

- Overlap material. Since multilayer insulating structures have considerable weight, the surface on which they will be mounted must withstand such a load.

Sound insulation materials can be divided into types:

- Tough. For such insulators, the sound absorption coefficient is not higher than 0.5. This type includes materials based on granulated mineral wool, vermiculite, pumice, foamed perlite.

- Semi-rigid. They have a noise absorption coefficient of up to 0.75. This type includes compressed mineral wool, polyurethane foam, polystyrene.

- Soft. They have the highest sound absorption coefficient (up to 0.95). These include glass wool, stone wool, foam rubber.

Materials for isolating the room from sound, description, their advantages and disadvantages

There is a huge selection of soundproofing materials on the market.

Consider in detail the most popular:

- ZIPS panels.

ZIPS-panel is a sandwich of mineral wool or fiberglass and gypsum fiber sheet.

Important! For the device of sound insulation inside the premises, it is better not to purchase ZIPS with fiberglass, since these fibers are dangerous to human health.

For attachment to the surface, special units are provided. The panels are interconnected using a tongue-and-groove connection. From above the system is sheathed with drywall. Such a system can also be used in cases where sound insulation of only a ceiling without walls is required.

Advantages of ZIPS panels:

- Sound insulation of walls and ceilings with the help of such panels is done quickly and easily with their own hands.

- High rates of isolation from air and impact noise (additional noise isolation from 10 dB)

- Lack of frame.

Cons of using ZIPS:

- The thickness of the system can reach up to 13 cm.

- High price.

- “Texound”.

This material, which has recently appeared on the market, is a thin membrane made from aragonite.

Material advantages:

- Flexible, easy to install.

- It protects against airborne noise (up to 30 dB).

- Durable

- Moisture resistant.

- Not subject to decay.

- Thin material, suitable for all surfaces. This material is a solution to the problem of small rooms where a bulky system will essentially “eat up” an already scarce area.

By cons include a fairly high price.

It is most effective to use this material in combination with mineral wool soundproofing, which provide sound absorption.It can also be mounted for its thermal insulation from walls and ceilings.

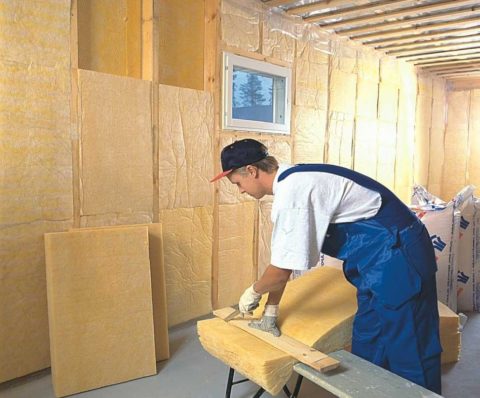

- Mineral (basalt wool).

This material perfectly reduces impact noise, durable, frost-resistant, fireproof, environmentally friendly. However, it absorbs water, so protection against moisture must be provided when using it.

- Cork coating.

- This material is of two types - roll and plate.

- The thickness of the plates can reach up to 3 cm.

- Installation of the coating takes place directly on the wall with glue, coating not only the surface of the soundproofing, but also the joints.

- Since multilayer improves insulating ability, it is better to stick several thin layers of coating than one thick one.

- Cork has a good decorative appearance, is environmentally friendly, it does not attract dust. However, it mainly plays the role of isolating impact noise.

To enhance performance, cork should be combined with good sound-absorbing materials such as mineral wool.

- “Shumanet BM”.

This insulation is made of stone wool with a layer of fiberglass lamination on one side. With a plate thickness of 50 mm, it has excellent sound absorption (up to 0.95). This material is good soundproofing on the walls and ceiling.

- “Isoplaat”.

These coniferous wood boards are available in thicknesses of 10–25 mm. Good absorb noise coming from outside. Their isolation index is 23-26 dB.

Sound insulation installation

As an example, a step-by-step instruction for installing the material “Shumanet BM” on the walls is proposed.

| 1. Clean and primed wall. | |

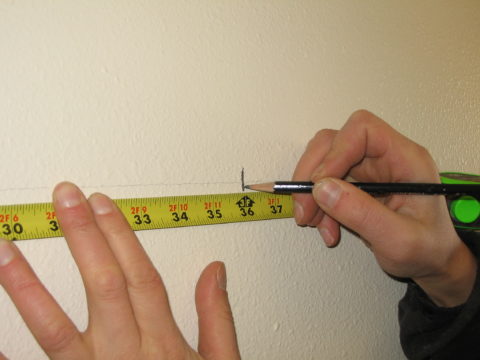

| 2. Mark for fixing the crate. The pitch of the frame is determined by the dimensions of the plates (500 mm) and should be 450-480 mm. | |

| 3. Fasten the details of the lathing (experts advise using a wooden frame). Between the wall and the frame elements, a soundproof layer of thin material should be made. | |

| 5. Install sound insulation. | |

| 6. Apply a breathable membrane to the sound insulation. | |

| 7. Mount plasterboard cladding. |

In order to better familiarize yourself with the nuances of installing sound insulation, we suggest watching the video in this article:

In conclusion, I want to note that the key to comfort in a house is to a large extent a correctly installed soundproofing of the wall and ceiling, which is performed using correctly selected materials.