Wood ceiling decoration - wise decision

Interestingly, now there are such owners of houses, apartments who do their own whitewashing and overhaul twice a year? Ask why exactly twice?

Because they were preparing to celebrate the autumn holiday in November, and the big Easter holiday in the spring. Finishing ceilings with wood and other finishing materials appeared much later and freed a large part of the population from unnecessary waste of time, effort and nerves, when through "I do not want" I had to repair plastered ceilings.

Fight cracks, cut joints between slabs and repair them again and again, remove expanded plaster. Creepy memories.

The content of the article

Good old wood, good of choice

The tree never went out of fashion, it was simply transformed from simple lumber to complex products, which was facilitated by advanced construction technologies. The use in the construction of logs, glued beams made wooden houses newly popular and sought after.

So:

- Their big plus attractive external and internal appearance without additional finishes, although facing works give originality, originality, individuality to the interior.

- In wooden buildings, a natural and non-alternative choice is a harmonious and beautiful wood finish of ceilings and walls.

- A specially selected photo at the top shows that wood for ceilings can be used not only in wooden buildings, and the ceiling does not have a perfectly flat surface. It’s not even necessary to say that the surface was specially prepared for further finishing.

- The tree has excellent technical characteristics, creates comfortable conditions and cosiness in the house, promotes natural ventilation in the room.

- The uniqueness of physical and technical properties and characteristics, environmental safety, naturalness and attractiveness of textures, turn wooden products into irreplaceable elements of many construction projects.

- The most popular lumber can be attributed to a wooden lining, the price of which is available to a wide range of consumers, and the quality corresponds to solid wood. Lining has taken a leading position among finishing materials at summer residents.

- The key advantages of the lining include its excellent sound insulation, ease of installation and repair work, material flexibility during machining.

Attention: High moisture resistance provided this material with its segment of the construction market and has become an important direction for many manufacturers in the sale of lining for baths.

Preparing the lining for installation

The lining is not always in the necessary condition and has a presentation ready for immediate use:

- Often it requires cleaning from dust, chips, sawdust, dirt, special attention should be paid to the cleanliness of the grooves.

- Not idle curiosity raises the question of whether it is necessary to treat the lining with special antiseptic agents against insects and mold? If necessary, when, how many times and by what?

- Ideally, the instruction recommends the first impregnation before lining trim together with the crate to which it is mounted.

- Final processing is carried out after installation, this requirement is relevant for rooms with high humidity, that is, in baths, although experts advise to process wooden surfaces at least twice a year during active use of the room.

- It remains to choose what. Drying oil is used for external and internal wood treatments, but does not protect the material from the effects of steam.

- Acrylic varnish protects against ultraviolet radiation, allows you to maintain a natural color, but emits a strong odor at high temperature.

- Solvent varnish is a good antiseptic. Low cost, but not suitable for lining the sauna and bath, emits toxins and a pungent odor when heated.

- What is left? In the video, masters use specialized impregnation from a combination of elements with certain advantages. There is no smell, the product is resistant to high temperatures and high humidity, has no contraindications to application to the surface.

Attention: When using larch lining, it does not need to be additionally treated with an antiseptic, due to the sufficient amount of natural resin, which protects the wood from insects, mold and rot.

- After processing the crates and wooden lining with special compounds, they need to give time to dry.

- To comply with the painting technology requires a simple set of tools.

- Capacity for special composition or paint.

- Airbrush, paint roller, brushes.

- Protective clothing or clothing that you don’t mind stain and throw away later.

- Rubberized gloves, goggles, respirator for respiratory protection.

- Solvent. The choice of composition for processing depends on personal preferences and financial capabilities, but saving on your own health is simply inappropriate.

Easy installation conditions

Typical Options ceiling finishes a tree stands out among a variety of offers. It is necessary to determine the type of frame, although the installation processes, regardless of the type of material, are practically the same, preference is given to beams, rather than a metal profile.

The bars allow you to get an inexpensive, reliable design, without work on leveling the ceiling. A metal profile is more expensive, and work is more difficult to do.

So:

- Before proceeding with the installation of the frame on the ceiling, it is necessary to determine the direction of the lining. The longitudinal arrangement of the lining requires a frame device across the room and vice versa.

- Sometimes a combination of the directions of the slats is used, or the ceiling is divided into zones, then it is especially important to carefully approach the design of the crates.

- Before finishing, the location of joints and interface zones is determined in advance.

- The docking lines are ennobled or even masked in general by special joints or fillers, which are offered in stores.

- The frame begins with guides along the edges, a reminder of the need for preliminary marking will not be out of place.

- Holes with a diameter corresponding to the fasteners are drilled in the uneven bars. It is desirable to select the extreme guides with a cross section of 30x30 mm or 50x50 mm, and the distance between them remains equal to 35-50 cm.

- Actually clapboard ceiling decoration starts with mounting and attaching the rails to the frame one after another.

- Joints are maintained between the slats, edges are adjusted, and between the planks and the wall a gap of 1.5-2 cm is provided, the house will shrink for another 2-3 years.

Attention: Take your time to finish the interior of the newly built house. Experts advise to wait a year or a half for the structure to settle.

- The joints of the planks are closed by the strips, and the interface with the wall is hidden by skirting boards.

Mounting the lining to the ceiling

The option of finishing the ceiling with wood depends on the choice of fixing the lining to the ceiling.If the ceiling surface is flat and the room is dry, then the lining can be mounted directly to the base of the ceiling, this is the maximum ease of installation work.

So:

- In the spike of the bar, a hole is drilled under the screw, under the hat of the cut itself. After mounting the lining, the hole is closed with a dowel, it is cut and everything is ground.

- The stapler mount has its own characteristics so that the spike of the next plank can fully and effortlessly enter the groove, the stapler bracket must be recessed in the lining array. To do this, the brackets are driven at an angle directly into the groove.

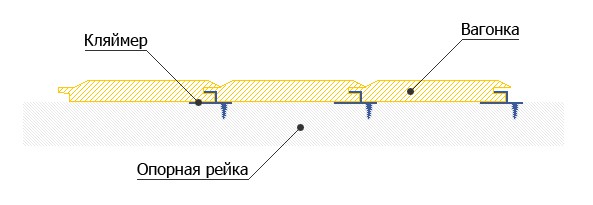

- Kleimers are the most practical way to fix the lining for today. On the back wall of the groove of the lining there is a kleimer attached to the surface with nails or cuts itself, thereby fixing the lining itself.

Next, the Kleimer is attached to the next board, a spike groove is joined and the Kleimer is again attached.

- The first board is fastened with cuts on the bottom side, screwed in, the other cut is installed in the spike in the upper part, the next panel is placed on the spike with a groove and fastened with the cut itself through the spike and the process continues.

- Finishing nails are used when lining follows one after another.

- Lining with nails is attached to the crate, for which fasteners are driven into the center of each plank.

- In this installation there are two poles - fast work is neutralized by an aesthetic type of structure.

The wood trim of the ceiling places some demands on the material.

Attention: Be sure to check the condition of the lining. It should not be wet, so that cracks and crevices do not appear when the house begins to heat up.

Lining is joined in two ways - in a checkerboard pattern or joint in joint. Sometimes when installing simple elements, which can include lining, it is necessary to make complex calculations related to the geometry of the roof, walls, with internal and external corners.

Imagine the gaps obtained during the design of corners with erroneous calculations that can negate the efforts of workers. If all the work is carried out in accordance with the technological map, then such a ceiling for a solid, solid house will be an ideal choice.

It impeccably approaches the patriarchal interior, is in tune with the walls, floor and other elements.