How is a home imitation of timber made

Quite often, finishing a house under a beam is chosen by modern developers for their country houses. Upon closer examination and apparent simplicity, when used on exterior or interior decoration, it gives a decent result.

It is advisable that the work with material imitation of the timber, performed by experienced craftsmen, although you can do it yourself, experience is acquired and needs to be acquired.

The content of the article

Why imitation of timber

By and large, imitation of timber is a material that can be attributed to the type of lining, which differs from it in few indicators.

So:

- The lining is mounted vertically, the imitation of the beam is horizontal and the tongue-and-groove joints allow the structure to look as if it was built of whole beams according to the "old grandfather way", only of very high quality materials.

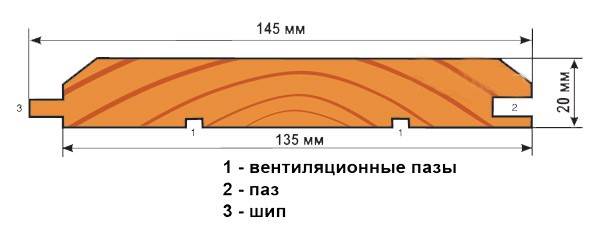

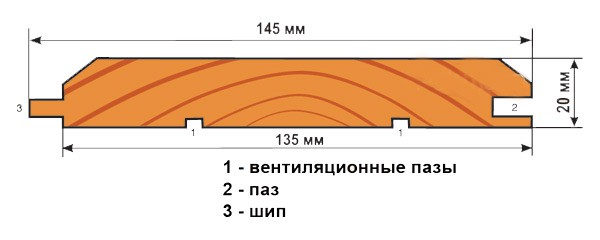

- The width of the imitation beam is not less than 110 mm, the thickness is 20 mm or more, otherwise the material loses the appearance of a real beam, and the length is of standard sizes - 3 m and 6 m.

- The working part of the imitation of the beam looks and repeats the natural beam only with rounded edges and a flat front surface.

- Home decoration imitation of timber refers to a fairly economical option.

- The “Finnish” style reminds and acquires the appearance of a house.

- A reliable solution, a strong and durable structure looks as if folded from the crowns of a solid bar.

- Strength and durability of the material laid down by the process. The boards are sawn on a sawmill, dried in special chambers, then refined, sanded on the front side and special channels are selected.

- The technology of finishing with imitation of the beam provides for the manufacture of products in two parts, in order to avoid stress in the wood, and to minimize deformation processes.

- The most popular are products from Siberian larch and pine.

- It is widely used in the decoration of wooden, stone, cinder block, foam block, aerated concrete houses, and if a board with a thickness of 30 mm is used, then this is ideal for sheathing a frame house. It remains only to treat the walls with an antiseptic, decorative impregnation and insulate the inside.

- High-quality wood, from which the imitation of timber is made, conveys its qualities for excellent sound insulation and environmental safety to the manufactured material.

- Imitation of a beam creates and maintains a natural microclimate in the room.

- A narrower board is used in interior decoration to visually increase the height of the ceilings, and a wide one is used for external work.

Note: To reduce the cost of home decoration will help drawn up an estimate, which provides for all circuit solutions and takes into account technological nuances.

General rules for finishing imitation timber

Two types of work indoors and outdoors on finishing a finished house, perform basic and secondary functions. Exterior finish under the beam is primarily used for protective functions and only then for decorative purposes.

Interior decoration performs tasks exactly the opposite. Instructions for the sequence of operations of sheathing imitation timber is quite accessible.

So:

- It is necessary to prepare the panels themselves, waterproofing, thermal insulation, bars for the installation of the crate, self-cuts, staples, kleimers, level, paintwork and antiseptic.

- About half a month before the house sheathing, an imitation of timber with a small margin is purchased.

- Storage should be organized under operating conditions, so that in two weeks the humidity of the panels is equal to the environment. This will avoid cracks, skew and other defects that occur after the adaptation period to the local microclimate.

- The walls of the house are cleaned of dirt, swept away from dust by watching videos and photos, there is a real opportunity to do these work yourself.

Imitation of a bar on external walls

So:

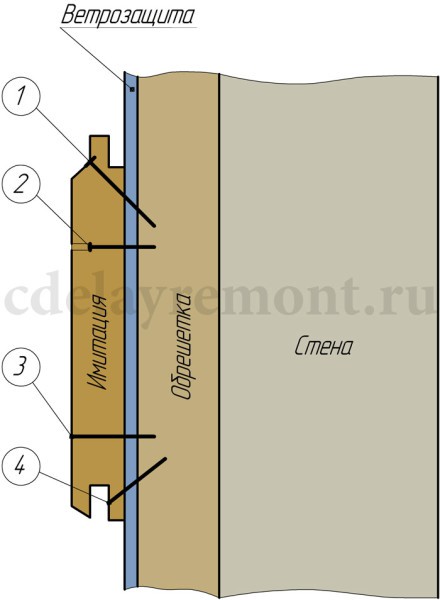

- A waterproofing layer is applied to the cleaned surface of the wall, covered with sheets of vapor-waterproofing with an overlap with an approach of 100-150 mm.

- At the top of the wall, the sheets are fastened with aluminum tape, joints and unwanted breaks are also glued.

- On the vapor barrier, the crate is mounted vertically, because the imitation of the beam of the finish will be fixed perpendicular to it, you need to make sure the wall is even.

- The bars for the crate previously treated with an antiseptic and a refractory coating should have a thickness equal to the thickness of the insulation. Everything is calculated in advance and the distance between the blocks is determined so as not to get a gap between the rail and the insulation was located tightly, the distance is made 10-20 mm less.

- The fastening of the bars is carried out with frame dowels on brick walls and by itself with cuts, nails on wooden walls.

- Insulation sheets are installed between the battens of the battens and fixed with special dowels for this operation. When weighting the weight of the plates with moisture, these fasteners will hold the sheets in a predetermined position and will not allow them to move and fall out.

- A wind-moisture protective film is placed on top of the finished structure to prevent the penetration of water and wind into the insulation layer.

- The film is overlapped and glued with double-sided tape, attached to the heater with brackets. Aluminum tape is used for gluing joints.

- On top, another layer of the battens of bars from 25 mm to 50 mm thick, pre-treated with the same compositions as the bars of the first battens, is installed. This allows ventilation of the outer skin from the inside, the fastening is carried out by itself with cuts to an almost finished design.

- Installation of imitation of the beam begins from above, although professionals recommend that the bottom of the wall begin installation and place the spikes up. The grooves will be protected from moisture and stagnation.

Attention: Regardless of the start of installation, whether top or bottom, a distance of 50 mm is left for ventilation of the structure.

- Between the boards it is necessary to provide a small gap of 1-3 mm to prevent distortion during seasonal changes in temperature and humidity.

- The first board is screwed itself by cuts to the additional crate, the next is inserted into the groove and hammered through the intermediate board.

- The imitation of the beam is fixed with finishing fasteners and here it is necessary to pay more attention to this seemingly simple operation. Nails allow the material to move slightly with changes in the environment, when the imitation of the beam can bend and “play”, and the cuts themselves cause cracking.

If sheathing with imitation of timber was carried out in violation of standards, then nails can provoke a divergence of seams, so think.

Imitation of a bar during internal work

Before proceeding to the interior decoration, it is necessary to lay the base of the ceiling, floor, walls of the water supply, sewage, heating, electricity and other cables for video surveillance, television, the Internet, that is, something modern man can do without.

If you do not do all these work in advance, you have to figure out how to place it; all this diversity is beautiful from above.Even laid in special cable channels or corrugated, flexible bases, such stickers on the surface of the finish look rude and can spoil the entire design.

So:

- Before use, the material is aged without packaging for 5-7 days in the room where work will be performed from it.

- Finishing is performed in a limited, enclosed space, which constantly has a desire to save. The preparation of the walls is done more carefully than outside.

- When installing the lathing, the protruding parts of the walls grind off at the points of fastening of the beams of the frame, the entire wall does not need to be worked through. The frame of the lathing itself is made of small-thickness whetstones located at a distance of 60-70 cm.

- The rest of the imitation of the beam, the interior finish remains unchanged.

- Inside the house are located not only straight planes, but also complex ones. Attic surfaces of attics, supporting columns, various niches (see How to finish a niche in the wall and in the partition), beams with their corners, transitions and additional difficulties in decoration.

There is a reason to find out what the price of the question is. If it is installed per square meter, then small and labor-intensive work will cost less. - The tree traditionally goes well with textiles, wallpaper, stone texture. However, many owners prefer finishing from one material, including the ceiling.

- The interior imitation of the beam for the ceiling should be thin.

- It is mounted on kleimers or self-tapping screws, since the load on these fasteners is quite high. Sheathing with imitation of a beam of a ceiling refers to a complex process with many nuances and questions.

How to carry out the installation correctly, in which direction the spike should look, where it is installed outdoors or indoors. - It is likely that you will have to cut the boards along.

- When you receive small cracks in the junction between the ceiling and the wall, it can easily be hidden behind the ceiling baseboard.

The use of imitation timber in the interior decoration may seem absurd. Why hide real logs under their artificial replacement?

Often such walls cannot be repaired or their restoration is much more expensive. Interior decoration This material meets all modern safety requirements.

You can always choose the most suitable option for individual specific tasks and goals of the selected object.