Panels for exterior decoration of the house: such a facade can be done with your own hands

Plastic panels made of polyvinyl chloride (PVC) are widely used for exterior decoration of houses.

This is a modern, high-quality and economical finishing material that will help to quickly and beautifully clad the facade of your home. And the abundance of colors will easily solve any design ideas.

The content of the article

Exterior home decoration with plastic panels

Plastic panels for the exterior cladding of a house must meet the following requirements:

- not be exposed to ultraviolet rays;

- have high frost resistance;

- must be fireproof;

- resist sharp temperature changes;

- 100% resistance to moisture;

- long service life (up to 20 years or more);

Do-it-yourself installation of PVC panels is not difficult.

To do this, you will need an assistant, a few days of free time, as well as the materials and tools listed below:

- electric drill;

- screwdriver;

- hacksaw for metal;

- level;

- hammer;

- roulette;

- screwdriver;

- dowel nails;

- self-tapping screws;

- kleimers;

- a sufficient number of plastic panels;

- accessories for finishing PVC panels;

- wooden beam (if you are going to insulate the outer walls with expanded polystyrene plates, then take bars 5 cm thick);

- if you plan to arrange a ventilated facade, then fix a beam 3 cm thick on the existing crate;

Tip: Before installing the crate, treat the bars with a solution from the fungus.

- The first beam must be fixed in the corner. All subsequent bars should be fixed every 0.5 m and the last beam should also be installed in the corner.

- In the intervals between the bars on the adhesive solution, lay the foam plates.

PVC panels must be mounted on the surface on which the accessories are already installed - these are window tides, corner risers, etc.

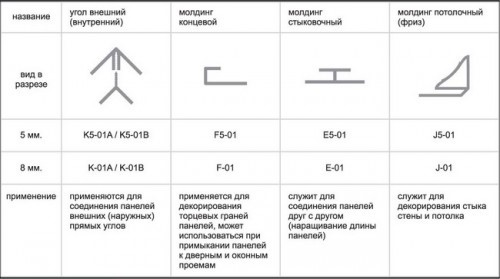

The figure shows the various elements, the so-called moldings, which will help you in the installation process of panels. The moldings help to hide the joints of the panels in the corners and in the joints of the panels along the length, as well as in places adjacent to the window and doorways.

So:

- We begin to install the panels from below by installing the initial bar.

- Having set the starting bar, we check its horizontalness by level.

- Each panel has upper and lower mounting shelves.

- We lower the lower shelf into the starting bar, and fasten the upper shelf to the crate with the help of kleimers or screws.

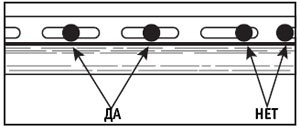

Fixing shelves on the panel have oblong holes for fastening. This shape of the holes helps the panel expand freely when the temperature changes.

Also, for free temperature displacement, it is not allowed to firmly fix the panel to the crate with self-tapping screws.

- We insert the mounting shelf of the next panel into the groove of the previous one, and fix the top to the crate.

In this way, all panels are mounted. For decorating joints in corners, when connecting panels, when adjoining panels to window and door openings, use appropriate moldings.

Characteristics of plastic panels

Plastic panels for exterior decoration of houses have many advantages, due to which they have been widely used:

- very simple installation, the ability to do the work yourself;

- hide all wall defects;

- the ability to close all communications suitable for the house (pipes, wires);

- plastic panels can imitate any natural finishing materials;

- an extensive color palette makes it possible to fulfill facade decoration for every taste;

- PVC panels will last for many years without losing their characteristics and colors;

- perfectly protect load-bearing walls from precipitation;

- not subject to corrosion;

- high frost resistance;

- fireproof;

- one of the most economical materials;

- environmentally friendly, harmless to health;

- very easy to maintain;

Facade decoration with Japanese panels

Today, the building materials market is filled with various types of panels for ventilated facades. But against this background, facade panels stand out panels for home decoration production of well-known Japanese companies such as Nichiha, Inax, Konoshima, Kmew.

Product characteristics of these companies differ from similar products of European or American companies in technical properties and other features:

- All facade elements of Japanese manufacturers have the same dimensions:

- length - 3030 mm

- width - 455 mm

- thickness - from 14 to 21 mm

- All Japanese-made panels have identical mounting methods. These maximally simplified fastening methods allow the use of products of different companies in the facade cladding.

- Given that the products of all companies are different in color and have a different surface texture, you can create unique, inimitable designer compositions.

Front Japanese panels have the following advantages:

- excellent soundproofing;

- high thermal insulation can significantly reduce heating costs;

- panels are produced as durable and lightweight as possible and do not increase the load on the foundation;

- high fire safety;

- harmful substances are not used in the manufacture of panels and therefore they are harmless to human health;

- the panel coating is resistant to ultraviolet rays of the sun and therefore does not fade;

- in the manufacture of panels toxic substances are not used, which means that they are harmless to health;

- Japanese panels have a self-cleaning coating, all dirt is easily washed off by rain or water from a hose;

- the only drawback of fiber cement panels is their relatively high price and the cost of the frame device;

Installation of Japanese panels

Japanese panels, or as they are also called fiber cement siding, are used for ventilated facades. Fiber cement facade panels are attached to a wooden crate or metal frame.

Wooden crate is recommended for frame-panel houses.

The metal system can be used for walls that are made of the following materials:

- brickwork;

- wooden beam;

- expanded clay concrete blocks;

- slag concrete blocks;

- foam concrete blocks;

- monolithic concrete;

To create a ventilated facade with your own hands, you will need such a tool:

- level;

- drill with punch function;

- concrete drill with a diameter of 10 mm;

- metal drill with a diameter of 4 mm;

- diamond saw with a diamond coating of the cutting edges of the working tool;

- screwdriver;

- angle grinder for cutting metal profiles;

- scissors for metal;

- roulette;

- square;

amount facade materials (number of panels, metal profile, brackets, fasteners, sealant, paint) should be indicated in the design for the ventilated facade.

Japanese facade decoration involves the following preparatory work:

- removal of old plaster;

- restore damaged brick or masonry;

- complete construction work;

- install windows and doors;

- blind area around the house;

- summarize and consolidate all communications;

- determine the mounting location of the air conditioner;

- mark the place of installation of decorative finishes;

- After completing the preparatory work, we proceed to install the brackets that are attached to the wall with anchors.A paronite gasket must be placed under the bracket;

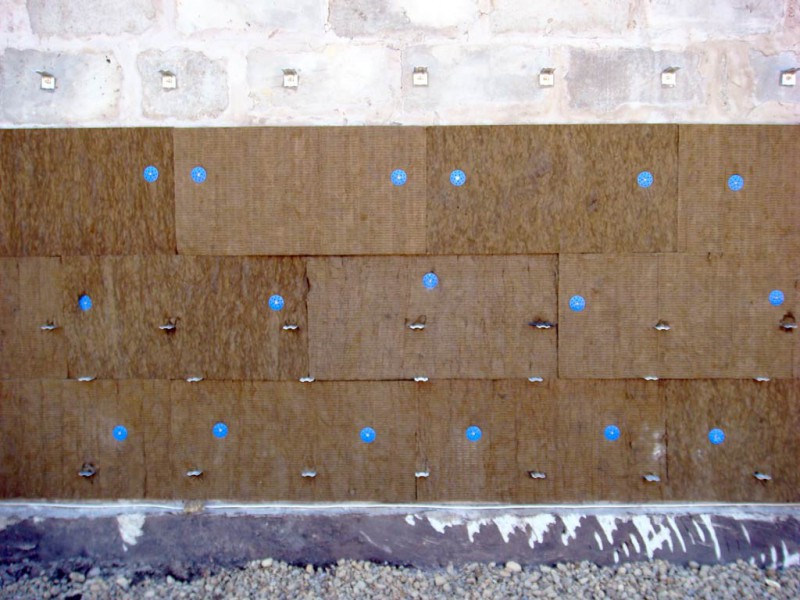

- The next stage is the installation of thermal insulation. Before installing the insulation, slots for brackets are made in it.

The insulation boards are fixed with dowels with a wide hat, which reliably presses the insulation against the wall. Each insulation plate is fixed with three dowels.

Places where the window frames adjoin the walls are insulated with mineral wool, cut into pieces of the required size. This is best done during the installation of window frames and ebbs.

- The next step is to install a vapor-permeable film. This film (membrane) has the ability to pass steam in only one direction.

If the film is not installed correctly, then all moisture will remain in the thermal insulation, and it will soon become worthless. Correct installation of the membrane is indicated on the packaging or on the film itself.

The vapor-permeable film is laid horizontally, starting from the bottom. The upper strip should go into the lower lap strip with an overlap of up to 20 cm.

The film is fastened through each insulation plate with two dowels:

- At this stage, we begin to mount the horizontal profile. It is attached to previously installed brackets with two self-tapping screws.

We connect horizontal profiles to each other so that the entire system is a single framework. - After horizontal profiles, we proceed to the installation of vertical ones. For this we use three types of vertical profile:

- Z-shaped;

- U-shaped 65 mm wide;

- U-shaped width of 80 mm;

If the panel joint is in the same plane, we use a U-shaped profile with a width of 80 mm, around the frame of windows and doors we use a U-shaped profile with a width of 65 mm, in other places we use a Z-profile.

- After you mounted the frame system, we begin to install decorative overlays on the outer corners. Corner pads must exactly match the front panels.

- Decorative corner pads are fastened with self-tapping screws. To do this, small holes are made in the attachment points through which self-tapping screws are wrapped.

Subsequently, the hats of the screws are putty and painted over to match the corner.

- The final stage is the installation of facade panels. Depending on the thickness of the panel, it can be mounted in two ways:

- open method - used for panels with a thickness of 14 mm. In this case, small holes are made in the panel where the fasteners are installed, through which the panel is fastened with screws, nails, or rivets.

Subsequently, the fastener hats are sealed with putty and painted with paint, which completely mimics the color and structure of the panel. - closed method - used for fastening panels with a thickness of 16 mm or more. In this case, the panels are fastened with kleimers.

The end surfaces of the panels have slots into which the kleimers are inserted, and the kleimers themselves are screwed to the frame with self-tapping screws.

- Before starting the installation of panels around the entire perimeter, we beat off a line strictly horizontally.

- On this line we set the starting bar.

- On this level, we begin the installation of the first row of panels.

- We fix the panels in the ways described above.

- After finishing the installation of the first row, we proceed to the installation of the second and so on to the entire height of the wall.

- At the final stage, grout the joints with putty and paint with special paint to match the panel.

The estimated cost of finishing the facade with Japanese panels of 1 m² will be - 948 p. (excluding the cost of materials). The estimated cost of facing 1 m² of facade with plastic panels is 700 p. (the price includes the cost of materials, delivery and installation of scaffolding, the installation of a ventilated facade).