Paneling of buildings - types of materials and technology

Upgrading the appearance of the building, while solving the problems of its sound and heat insulation, until recently, was not easy. But the development of ventilated hinged facade systems made it possible to solve this problem quickly and simply, and the panels used in them for cladding the building diversified our houses, made them beautiful, different from each other.

The content of the article

Facade ventilation technology

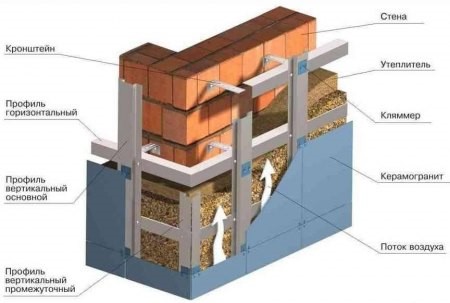

Device principle ventilated facades lies in the fact that the cladding panels of buildings are not attached directly to the outer walls, but to the frame mounted on them. Due to this, a ventilation gap is formed between the wall and the lining, in which air circulates, which eliminates the accumulation of moisture on the walls.

For reference. As you know, wet surfaces not only deteriorate faster and become a favorable environment for the growth of mold and fungus, but also significantly lose their heat-insulating properties. In the system of ventilated facades this problem is excluded.

The picture above gives a complete picture of the design of such systems, the heat-insulating materials mounted under the cladding often become an additional element. In this case, an air gap is left between it and the insulation.

There are different ways to frame and fasten the cladding to it. But, as a rule, installation is straightforward and can be done with your own hands.

For reference. Many manufacturers of building cladding panels also manufacture wall mounted systems for their products. And some types of facade panels can be mounted on a regular wooden or metal frame made of galvanized profiles.

It is the simplicity and reliability of installation, the possibility of simultaneous insulation and ennoblement of buildings, coupled with a wide selection of decorative coatings, and have become decisive factors in increasing demand and interest in such systems.

Types of facade panels

Among the materials used today for outdoor decoration, there are both familiar, traditional, and modern, made with the latest technology. And their price is sometimes much more affordable than the cost of high-quality wooden lining or other cladding options that were used before.

Most Popular Materials

We list the most popular finishing materials that appeared on the modern construction market:

- Fiber cement panels. The basis of the material is a mixture of cement with mineral components and cellulose fibers. After installation, the surface is painted with facade paint.

The minimum amount of organic matter in the material makes these cladding panels for buildings resistant to rot, mold and corrosion, durable, non-combustible. Their advantages can also include frost resistance, resistance to temperature extremes and sunlight, good sound and heat insulation properties.

And the disadvantages are insufficient impact resistance and high water absorption.

Note. Panels with a polyurethane or acrylic coating are practically devoid of the last drawback and do not need decorative painting.

- Metal panels. They are made of sheet aluminum or galvanized steel with a thickness of 0.5-0.6 mm.

Products on top are covered with a decorative protective polymer film of various colors, and on the reverse side - with a primer that protects the metal from corrosion. Resistance to moisture, frost, aggressive environments, impact resistance and incombustibility are the main advantages of this material.

But it does not have heat-insulating properties, therefore it is installed mainly after insulation of the facades. - Composite aluminum panels. Sandwich panels are also produced from aluminum, in which mineral insulation is located between the outer and inner layers of the metal.

Facing buildings Composite panels in some cases make it possible to do without additional insulation, since they themselves are distinguished by sufficiently high heat-insulating and sound-insulating properties. Having the same advantages as conventional metal panels, composite panels are less resistant to mechanical damage - bumps and scratches, since the outer layer of metal is very thin and is only 0.3-0.4 mm.

- Wooden panels. They differ from traditional lining in that they are made not of solid wood, but of split into fibers and pressed wood, coated with veneer or colored polymer film.

Being an environmentally friendly material, such panels have all the positive and negative properties of natural wood. They are an excellent heat insulator, resistant to low temperatures, durable, easy to process, but swell from moisture and do not withstand fire. - Composite wood-polymer panels. Available in the form of boards (siding) from a composite material obtained by mixing crushed wood with polymer binders - polypropylene, polyvinyl chloride, polyethylene.

Exterior building cladding composite panels It doesn’t differ from a wooden covering, but at the same time it is not subject to decay and spread of mold, insects do not start in it. But most importantly - it does not require care and annual staining or impregnation.

- Vinyl panels. They are made of PVC with the addition of modifiers, stabilizers and dyes. They can have different sizes, shapes, textures and colors, most often imitate wood, stone or brickwork.

The only drawback of such panels is the lack of strength at low temperatures, under the influence of which they become brittle and are afraid of shock. Other characteristics are excellent: it is waterproof, and fireproof, and resistant to fading and corrosion, and ease of installation.

- Porcelain tile. This is one of the most expensive materials, in terms of its characteristics practically no different from natural stone.

These include high strength, frost resistance, low water absorption, resistance to aggressive environments, excellent appearance. But, like stone, porcelain stoneware easily conducts heat and does not have good soundproofing properties.

Note. The instruction permits the installation of ceramic granite panels in a "wet" way - on adhesives directly to the brick or concrete wall of the building. But you need to keep in mind that if the installation is poorly done, heavy plates can come off the surface and fall.

- Thermal panels are also a composite material, the basis of which is foamed polyurethane, and a clinker tile with extremely low water absorption serves as a decorative coating. Thanks to this coating, the cladding has high frost resistance, withstanding sharp and frequent changes in temperature.

It does not rot, does not burn, does not require special care, but due to the toxicity of some components it cannot be considered environmentally friendly material.

For reference. Since the decorative panels themselves are also a heater, they can be mounted directly to the walls if they are fairly even. With large deviations from the level, a crate device is required.

Summary table

When choosing the type of facade finish, you need to be sure that the walls and foundation of the building will support its weight. Otherwise, they will have to be strengthened or choose a lighter material.

In the table below you will find the approximate weight of all the materials described in terms of square meter, as well as the manufacturers guaranteed their service life.

| Type of panels | Service life (years) | Thickness (mm) | Weight (kg / m2) |

| Fiber cement | Up to 50 | 812 | 10-1523-25 |

| Metal | Up to 30 | 0,56 | 9-10 |

| Composite aluminum | 30-50 | 4-6 | 7-8 |

| Wood-polymer | Up to 50 | 12 | 10 |

| Vinyl | Up to 30 | 1-1.2 (wall) 2.5-3 (basement) | 23-5 |

| Porcelain | More than 50 | 8-14 | 20-36 |

| Thermopanels | Up to 50 | 40-80 | 20 |

It is also necessary to take into account the weight of the subsystem (frame) and the thermal insulation materials used.

Conclusion

Facing the facade of the building with panels allows you to forget about the need for repair for a long time, and sometimes forever. Maintenance of such facades is also minimal - most coatings have the ability to self-clean, and in case of severe pollution, dust is washed off with water from a garden hose.

You will learn about the features and rules for installing panels by watching the video in this article and studying other site materials devoted to specific types of cladding.