Facing the house with expanded clay blocks

Expanded clay blocks used for individual construction, construction of houses and other buildings, they can be attributed to a series of new materials. They allow the construction of a house with their own hands in one summer season.

An example was the neighbors nearby, who, together with his wife, built a box of a house for the period May-September during off-hours and weekends. The motivation was rented housing, lack of money to buy an apartment and two children.

Photos and videos of a selection of finished buildings with a small plot of land will help you choose a house to your taste, now the dream of many citizens now.

The content of the article

What speaks in favor of expanded clay concrete

Building blocks obtained by vibropressing mixtures of cement, expanded clay gravel and water have several advantages:

- An ordinary block, smooth of expanded clay concrete SKTs-14R, measuring 390x188 / 196x140, has a weight of 10.9 kg, but in general the weight is determined by the parameters of the products and their purpose.

- Houses withstand a long operational period of 50 to 100 years with positive feedback if the processes are followed. Withstand 50 cycles of freezing and thawing.

- The thermal insulation characteristics of the material make it the preferred product in cold and hot climates.

- Ecological safety, availability, profitability.

- The foundations of multi-storey buildings experience less load when using expanded clay concrete blocks in construction.

- The flat surface and the optimal format of the blocks allows you to perform styling quickly, easily, save on solution.

- Houses from a facing expanded clay block are being built in a variety of architectural solutions. In block walls and partitions, you can make door and window openings without special equipment.

- The size and shape of expanded clay blocks are convenient for transportation by road, rail. Stacking is done in batches, on pallets, without any additional wooden devices. Unloading on a construction site, storing and storing them is also not a problem.

- It goes well with concrete, reinforced concrete, foam blocks and other materials.

- The use of blocks for building a house reduces heat loss in the building by 75%

Attention: The level of thermal protection and sound insulation of the porous expanded clay block is not lower than ordinary concrete.

- A set of positive properties and characteristics make this product universal. High construction speed is ensured, the amount of mortar is reduced, the speed of construction of buildings is reduced to 4-5 times, construction costs are reduced, because the cost of expanded clay blocks is lower than brick and at the same time, the reliability and quality of buildings are not lost.

- The disadvantages include unsightly appearance, some fragility, temperature changes have a negative effect on the surface of the product.

- The price of building a house from blocks is directly dependent on the cost of finishing facade materials. True, some contractors prefer to keep silent that after building a house from expanded clay concrete blocks, it must be faced and these works are not included in the estimated cost.

There is an alternative solution - expanded clay concrete blocks tiled.

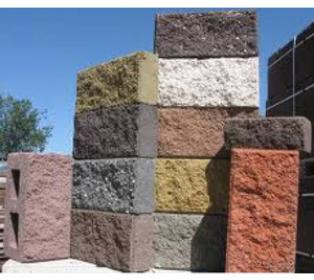

Decorative side of blocks

Expanded clay blocks with facing tilesthat reveal another decorative side of the product.

Conventionally, the blocks are divided and make up two large groups on this basis:

- Blocks are color. Surprising, but not for long.

- Clay, which serves as the basis for the production of expanded clay concrete blocks, cannot boast of a variety of colors. White clay, reddish-red, giving color to materials for construction.

- This does not bother when further plastering, or cladding with clapboard, decorative materials is supposed. Do you always need a cladding process?

- It can be assumed that construction is being carried out in a region with a warm, comfortable climate. Thick walls, and even more so, additional insulation in the form of plaster are not required, therefore, laying in one block will be sufficient.

- The problem of the exterior design of the building remains. The laying of facing expanded clay concrete blocks will be the first aid that comes to consumers.

- The block size can have parameters of 600x300x400 mm. What is this size talking about? In one block, a masonry of 37 pieces of ordinary brick fits.

- The construction of walls is carried out in blocks in one row. No need for external surface finish. The small thickness of the walls forms an additional useful area of the house.

- The load on the foundation is reduced by 3 times, due to the porous structure of the material.

Attention: The facing slab or decorative concrete does not stick and does not screw onto the surface of the block, but is one with it and has dark red, blue, yellow and other shades that look decent on their own without additional decorations.

- Blocks with a decorative coating are not only limited by a diverse color palette, but also have a unique texture.

- Lining the walls of expanded clay concrete blocks does not seem to carry unusual loads, structurally they do not differ from ordinary expanded clay, they can be empty or full-bodied. Only the front side distinguishes them from their relatives, it is she who addresses the audience and imitates a tree, natural stone, lining, texture plaster, that is, everything that industry produces today.

How to perform external cladding of a house from blocks

The appearance of buildings made of expanded clay concrete blocks wants to be the best. Expanded clay is not destroyed by moisture, and temperature changes cause damage to the walls.

What can be used for facing:

- Facing expanded clay blocks can be done with plaster, as the cheapest finish.

- With marble (seeFacing the facades with marble - what you need to consider).

- Siding.

- Natural stone.

- Brick lining is very popular.

- Paints for the facade and plaster give the surface of the house a certain appeal and texture.

- Plaster is able to protect expanded clay concrete from temperature changes.

- Ventilated facades are ideal for masking masonry imperfections. This facade allows moisture through the air gap between the wall and cladding, which prevents the destruction of the walls.

- The most economical process is siding, but here it must be said about the fragility of the panels and their susceptibility to destruction.

- Natural or decorative (artificial) stone, what to choose?

The choice of material is determined by its frost resistance. Decorative stone is much cheaper than natural and more economical with almost the same characteristics as natural stone, which gives a noble appearance to the house. - Thermal panels are perfect for strip foundations. When erecting the foundation, a distance of at least brick for the future facade cladding is provided.

The panels are heat-conducting, durable and belong to environmentally friendly material with a low cost. The instruction allows you to work with thermal panels even to "beginners" in the construction business.

Exterior decoration of expanded clay concrete blocks

Facing a house from expanded clay blocks is practically no different from finishing from other wall materials.

So:

- Plastering can be done with cement-sand and gypsum plaster.

- High adhesion of cement-sand mortar and wall material is ensured by almost the same composition of materials.

- The use of a plaster grid is optional, but it will not be superfluous. As a rule, a flat galvanized mesh with small cells is used.

- It is attached to the walls of expanded clay blocks with nylon dowels inserted into shallow holes at a distance of 200-300 mm from each other, into which the cuts themselves are screwed, fixing the plaster mesh.

- The gypsum mortar has a lower density, it is warmer and lighter, but before plastering the walls, it is better to treat it with a concrete contact, which increases the adhesion of the gypsum plaster to the expanded clay concrete wall.

- Facing a house with expanded clay block differs from ordinary wall materials in that they are thinner in size, but this does not reduce technical and other characteristics.

- There are other plaster components that are used without prior wall treatments. Mixture packaging contains such information.

Gypsum plaster reinforcement is made with a polymer stucco mesh, which is attached to the wall much easier and costs less. - Facing the walls with decorative stone, ceramic tiles does not require preparation of the base, and the tile can be glued to expanded clay concrete wall.

- The design of the lining, plastic panels, drywall requires attaching to the walls of the guide rails or steel profile.

Attention: It is not recommended to insulate the walls when finishing inside the building, you can use just “warm” plaster.

- Expanded clay facing half blocks do not differ from materials of usual sizes.

- They are used for fixed formwork, for internal partitions, for the construction of fundamental structures and wall structures, in private construction.

The advantages of new materials in their wide assortment, various shades and textures. All the nuances of beauty are inherent in the blocks themselves.

When laying them, it is enough to deploy them on the side that allows the inclusions of quartz to shine so that the hardness of granite, the texture of the cladding and plaster are visible.