Perforated plaster corner: how to use

The perforated galvanized plaster corner helps with the decoration of many parts of the room. Correspondence of these places to the designed design, the master finisher achieved thanks to experience and skill. After all, it is extremely important that the site is straight or oval, where necessary. Today, finishers come to the rescue to greatly simplify and speed up the work.

Today we will tell you where and how perforated plaster corner is used. Also in the video in this article you can find out additional information about the use of this material.

The content of the article

Where is the corner used

Finishing craftsmen try not to advertise that the beauty of flat walls is largely dependent on the edging.

This definition implies such areas of use of putties and stucco mixtures as:

- Connection of walls with floor and ceiling;

- Inside, outside corners;

- Arches, ducts, corners, channels and other similar structures

At its core, all accessories are perforated corners for plaster. There are only two main types of corners: arched and straight, which in turn are divided into different categories. The scope of their use is extremely wide, and covers almost all types of work related to plaster and putty.

Straight Perforated Corner

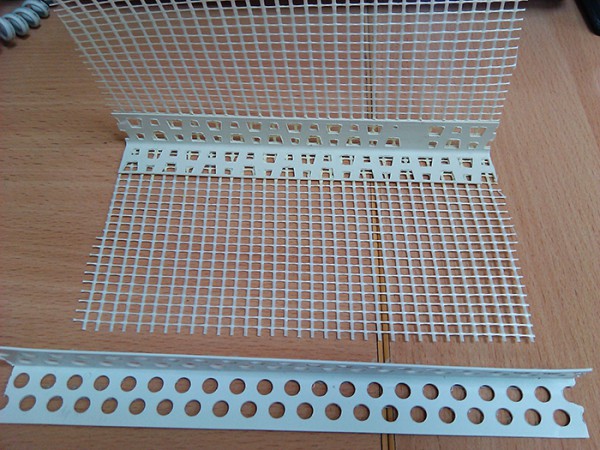

Perforated plaster corner is available in two versions, it is internal and external. The material for their manufacture is used different from plastic to galvanizing, and the width of the corner also varies.

Using this or that corner, it is worth starting from the task posed, because there is no global difference between them. Although the galvanized corner, in comparison with others, is more rigid. This property allows you to use it as plaster beaconespecially if it is wide enough.

Attention; To use the corner, it is necessary to choose scissors for metal of proper quality. Otherwise, poorly trimmed edges of the corners will interfere in the future.

So:

- If you use corners made of plastic, then you can even use a clerical knife to work with them. However, if there were no tools under your hands or there were no tools, the perforated corner can be broken with your hands. In this case, the edges will then have to be straightened with a hammer or pliers, or even manually.

- Straight perforated corner for plastering looks like the English letter "V". At the same time, its flat sides are perforated, and the top protrudes about a millimeter. It is characteristic that those corners where it is directed inward are called internal, and external, respectively, where the vertex looks outward. The top serves to guide the trowel, and perforation is necessary to secure the corner itself

Attention: You can cut a dozen corners of the required footage using a tape measure and a grinder. To do this, you need to fold the corners one to one, and then, after measuring the desired length, use the grinder. To work with a small number of products, you can use scissors, however, if there is a power tool not far, then it is better to use it.

Appointment of a corner and methods of its application

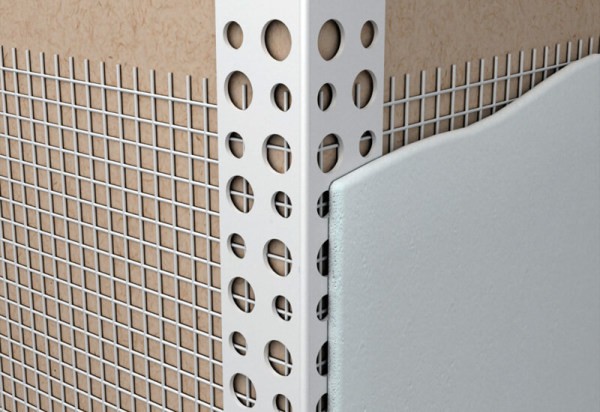

A perforated plaster corner is used to strengthen the angle and give the correct geometric shape.

There are two methods for installing this product:

- Crooked angle, in this case, if the radius is not large, you will need to make cuts along the stiffeners so that the corner takes the desired shape;

- Right angle, in this case, the corner is simply mounted on the plane in the form in which you purchased it.

Corner as a plaster beacon

In the first version, the corner will be used as a plaster beacon. To install it, the plaster lies on the main corner. It is worth noting that if you have sufficient finances, it is better to choose gypsum plaster, working with it is much more comfortable.

- Such a stucco mixture is applied not according to the edging, but with smears in the form of a cake. This is done to conveniently set the angle. A corner is set on the plane and level, using building tools, in particular the rules and levels.

Attention: If you mix gypsum plaster with cement or cement mixture, the lighthouse will rise within a few minutes, after which you can continue to work.

- In order to avoid overlapping of perpendicular planes, it is better to cut the working corners at 45 degrees. It is worth noting that it is undesirable to use an internal perforated corner as a stucco beacon. With its help, it is better to emphasize the straight lines of the edging.

- In places where the outer corner is subjected to frequent mechanical stress, it is worth using a corner that has a stucco mesh. Fiberglass plaster mesh in combination with a corner made of plastic or metal, reinforces the corner if necessary. Such categories of perforated corners are used as plaster beacons. Because, to hide the grid under the finishing putty, you will need to apply a layer of plaster thickness of at least 5 mm thick.

Attention: If you use a regular perforated corner as a reinforced one, you can stick a grid on its shelves - a sickle, capturing the wall. As such a mesh, materials such as interlining and fiberglass can be used. Putty can be used as an adhesive element.

Use of a corner as a protective pad

In the event that high-quality plaster has already been applied to the wall, the perforated corners for the plaster serve to protect the corner from gross mechanical damage and emphasizes its straight lines.

- Such a corner is installed like the first option. The difference is the use of a more liquid stucco mixture, and its layer should be as small as possible. For such tasks, as a rule, plaster corners made of plastic or aluminum are used.

- Moreover, for installation it is not necessary to use plaster mixes or putty. The corner is adjacent to the surface, covering it as the base is already flat. Installation of such a corner with a thin layer of plaster mixture as an adhesive element is used when working with products from gypsum plaster.

- It is important that these structures are properly assembled. For such work, a perforated corner is used, on whose shelves self-adhesive strips are applied, you can use such products by moistening them with water.

- In some cases, there is a need to connect the corners, in this case it is important that the connecting corners are made of the same material. This is due to the fact that different corners can have different sizes, which in the end result will adversely affect the finish.

Attention: If you often walk in the room, then it is better to use a galvanized perforated plaster corner. It is more rigid and better tolerates plastic loads.

Slope Finishing

The slopes on the windows and doors should be treated with special responsibility since during visual observation, they are involuntarily compared with door or window openings. In other words, the directness of the lines is evaluated.If you do everything yourself, then the attention should be on top.

- There should not be any minimal deviations from the door or window lines. You should also check the window openings for compliance with the level, they may fall over. Mostly with stucco slopes Wizards are guided by the level.

- Therefore, it is advised to use a perforated corner for this, which can also be used as a beacon. If during installation of slopes GVL or GKL were used, and at the same time the quality is poor, the corner will help to eliminate defects.

- It is also important that when working with a brick slope, sandwich products, installing gypsum board on a slope according to building standards and the rule, they must be plastered. The perforated corner in this case will contribute to the correct exposure of drywall.

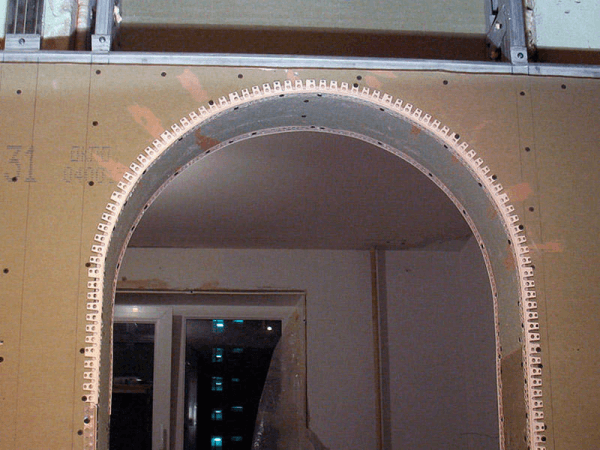

Perforated corner for arched openings

Working with right angles, in most cases there are no special problems. But how to bring to the best option arched, curly structures or ceilings in several levels?

After all, the usual construction tools pass here, a direct perforated corner will not help either. For these works, a special type of perforated corner is used, which is called “arched”.

- Such a corner is always made of plastic, and one of its shelves is cut into petals. This product design allows you to change configurations, for the most accurate match to surface bends.

Attention: When using an arched corner, be extremely careful, you will not be able to correct them. In this case, a corner is set exclusively visually.

- For this, the room should have good bright lighting and the help of a partner is desirable. Before installing the product, squeeze it, otherwise the petals will protrude from the plaster.

- An arched perforated corner can be either hard or soft, it depends on the manufacturer. A rigid corner is necessary when working with volumetric structures, where there are many smooth shapes and bends. Although, the price of it is usually higher.

- The bent arched corner tries to straighten, providing the necessary roundness of the lines and leveling the "angularity". When you try to use the corner on the small details of the design, where there are many cool transitions, it will break and it will be impossible to fix the job.

- For finishing steep transitions and arched openings (see How to finish an arch: forms of arches and types of decoration) with a small radius, it is worth using arched corners made of soft materials. The lack of rigidity in these products is fraught with the formation of hollows and tubercles in the future, which will ruin the smooth transitions. To avoid such difficulties, these arched corners are installed using plaster mixes. Moreover, this installation method allows you to correct visual defects during plastering.

- It is important that self-tapping screws and similar mounting elements will not spoil the processed lines. In order to make the corners look more attractive, it is worth installing them with a little effort, a stretch.

Angles in terms of economics

Perforated corners for plaster, and other similar products have a relatively low cost in the range of 40-50 rubles. This applies to corners made of plastic and aluminum.

The same galvanized product would cost a little more, about 60 rubles. A rigid arched or reinforced corner will cost much more, approximately 150 - 200 rubles.

- Naturally, when decorating an entire cottage or private house, the number of such corners will be in the tens. After all, docking does not always work, and many products can go into construction waste. In this case, the estimate will be impressive. However, the reliability of protected corners with these accessories also costs money.Do not forget about the speed of decoration using corners, and a positive visual effect.

Attention: Do not confuse the finishing corners with the plaster, they are completely different products that solve different problems. The finishing corner is used at the final stage of decoration. For its installation of a corner made of plastic, it is optimal to use liquid nails. Keep in mind that corners for decoration are also divided into types and subspecies.

- When making an estimate of home decoration or repair, it is definitely worth considering the costs of the corners. Otherwise, the effect of the finishing work will be incomplete. When choosing such products, it is worth relying on the opinion of the master, he will have to work with them.

- Also, with its use, there will be significant savings in time. Indeed, in this case, bringing the angle does not require much time.

Perforated perforated corner perforated will help you do the job quickly and efficiently. Therefore, you should not be afraid of the cost of its purchase, it will pay for itself and that’s for sure. And the instruction will help you make the right choice.