Barite plaster: application technology

X-ray protective plaster is not often used. But there are areas where you simply cannot do without it. Today, barite X-ray protective plaster will be considered: application technology, flow rate and composition.

You will be able to get the necessary information that will help you deal with the consumption of plaster in more detail. I immediately want to say that its price is quite high and it is better not to do it yourself with your own hands. It is better to entrust it to specialists.

The content of the article

Where is barite plaster used?

Barite X-ray protective plaster is mainly used in medical institutions (tomographs, X-ray rooms). The composition of barite plaster includes barite concentrate, or we can also say that it contains barite sand.

Caution: This finish serves as an excellent protection for personnel, protecting them from harmful radiation.

So:

- As a rule, such plaster in the X-ray room is used constantly, it is just an additional protection for workers.

- Compared with lead plates, this material is cheaper, and therefore it is used much more often. Not so long ago, such plaster was used to decorate offices and residential premises, because it helps to lower the natural radioactive background. But for its use in rooms where people live, it should be protected from the effects of barite. Another layer of finishing material is applied to the plaster. The structure and its composition here allow it to be used quite effectively.

- Barite plaster can also be used in factories in which there is x-ray radiation, in laboratories where they are conducting research, and also as a protective layer in storages with radioisotope sources.

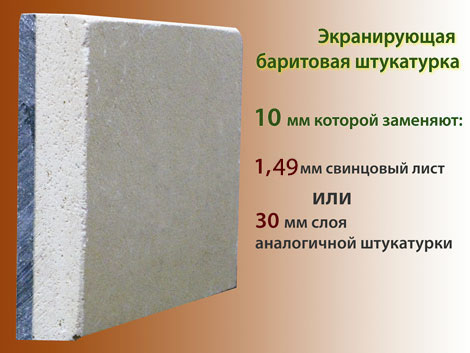

- The main advantage of this material is its protection and low price. That is why it can be easily taken for work instead of scarce and expensive sheets of lead, which have the same characteristics.

Attention: The disadvantages include the fact that for good protection the layer of plaster should be at least twenty - twenty-five millimeters, but lead plates in this situation can have a thickness of a millimeter.

How to choose

Of course, the method of preparing the finished solution by mixing the ingredients on the object itself does not allow for accurate dosage. In such a solution, it is almost impossible to monitor their quality and quantity. Therefore, for a mixture that is made in this way, no certificates are issued.

There is only an instruction on how to do it. Calculation of barite plaster is done by the application layer, but it should be at least 2.5 cm.

The main disadvantages of this option include:

- Finished material weighs too much;

- Barite plaster consumption is significantly greater than the cement composition;

- A lot of waste remains;

- The need to apply a large number of layers;

- Protective properties are not evenly distributed;

- The layers are difficult enough to care for, so there is always the likelihood of defects;

- The goal is achieved in a long time.

The list of pluses includes:

- The possibility of preparing a mixture of available materials, in addition to barite concentrate;

- Ready solution not too expensive, which hides the high price of work and shielding.

Caution: An alternative may be a solution that is made at the factory.In this case, you don’t have to worry about the quality of the mixture, the reliability and uniformity of shielding, which is confirmed by special documents. But it is worth noting that this solution also has its drawbacks.

Cooking Barite Plaster

The technology for applying barite plaster is quite simple. The instructions below.

To prepare the solution, barite sand and cement are used. As for the second component, Portland cement is usually taken, whose brand should not be lower than three hundred.

- The amount of cement required is calculated based on the parameters of a particular room, the level of radiation or radiation. It is from such data that the thickness of the layer that performs the protective functions will depend.

Attention: If according to calculations the layer should be more than five centimeters, then it is more advisable to take a barite plate.

- If we talk about sand, it represents a fine material, whose fractions have a size of 1.25 mm. Barite dust can also be taken to prepare the mixture. But in any case, it will be necessary to carefully monitor the content of the material in the finished solution, which should be approximately eighty-five percent. This amount of material is important, despite the size of the filler fractions.

- To barite plaster was a plastic field, you need to add PVA glue to the mixture. Glue, cement and sand are diluted with water to obtain the necessary consistency. But do not forget that the ratio of mixture to liquid should be more than one in four.

Features of working with plaster and how to apply it

If the room, which will be subjected to plastering, has the possibility of infection by radiation, then the mixture should be superimposed in layers. Each of them must be at least twelve millimeters.

Caution: Since the material is toxic and has high flowability, the thickness of the applied layer is limited. In the end, the protective layer may not be as strong as expected.

So:

- In the floors, the material is brought into the next room by 20 mm. If a reinforced concrete slab is used as a ceiling, then the plaster layer will be six and a half centimeters.

- Due to the high flowability of the material, it is necessary to reinforce the mesh during the work. In this case, you need a couple of grid layers with different cells.

- To do this, we fasten the grid to the wall with dowels (see How to fix a stucco mesh to a wall) and apply the finished mixture to it. The next coat can be applied only after the starter dries. So that as a result, the finish does not begin to crumble, you need to leave it for another three days and only then start grinding it.

- Barite plaster is applied by hand. For floors and walls, the minimum thickness should be about 3 cm, and a five-centimeter layer is applied to the ceiling. Do not forget that you need to process both sides of the wall. During construction work, the temperature should be fifteen degrees, and humidity - high.

- After all work is completed, such conditions will have to be kept in the building for about two weeks. In order for fire-resistant plaster to protect the walls of wood, the standard size of the layer should be increased by one centimeter. When calculating the required material, you need to take into account that up to twenty kilograms of solution will take per square meter.

How to calculate the amount and consumption of barite plaster

Calculation of barite plaster is done by the application layer. To correctly calculate the thickness, you need to follow some building rules that govern the application of such a composition. Since the main protection against radiation is a coating of lead, the recalculation of the volume and mass of the composition should be in lead equivalent.

- The problem with the calculation is that all manufacturers, despite the accepted standards, may have different amounts of barite filler in the composition.The maximum permissible minimum is considered to be 85% of the total composition. Some manufacturers will have it in this range, while others will have ten percent more.

- In this case, resort to the help of supporting documents, which display recalculations of the layer thickness, recorded in the technical documentation for the equipment itself. Firms can also add information on barite plaster consumption per m2 to these papers.

- In the initial design calculations, an amount of twenty kg of barite plaster with a consumption of 1 m2 of coating can be taken as an approximate norm. If the minimum bar at the layer is equal to eighteen millimeters, then this figure, accordingly, will have to be multiplied by a factor of 1.8.

- If, for example, the layer is more than ninety mm, then the norm should also be increased nine times. But getting the total area of the treated surface can be calculated without any problems. The value obtained is also multiplied by its value.

Attention: During dilution with water, do not forget about the proportions - per kilogram of the mixture in dry form accounts for a quarter of a liter of water. But such a formula cannot be called accurate for compliance, because the amount of fluid can vary. It all depends on various related circumstances, for example, absorbent features of cement or temperature conditions.

Plaster for X-ray rooms is quite a responsible matter and here you must have practice. It is better to take a high-quality and proven composition, for example fullmix barite plaster, which has proven itself on the positive side. After all, a person’s life can depend on this composition.