Mortar for plaster: proportions when cooking

Plaster mortar is an indispensable material for repair, insulation, leveling and even decorative finishing of various surfaces inside and outside the building. But for each type of work a specific composition is used.

For example, lime is perfect for aligning internal walls. mortar for plaster (see how to make it correctly) - the proportions and proportions of all its components may be different. What do they depend on and how are they selected?

The content of the article

Types of plaster mortars

First, find out what components can be part of protective and leveling mixtures, and what they are. Mandatory ingredients are water and sand, which acts as a filler.

And the main properties depend on binders, which may be cement, gypsum, lime or clay. Their proportion for plaster relative to water and filler determines the quality of the mortar.

Component Specifications

To understand why one mortar is used for plastering the plinth, another for the facades, and the third for the internal walls, you need to know the properties of the materials of which it is made:

- Sand. It differs in the size of the fractions and the place of extraction. The best river sand is considered to be the best for plaster, but it is also sieved before use to remove foreign matter and large particles.

- Cement. After hardening, it acquires high strength, resistance to water and weathering, well resists serious mechanical loads.

For reference. Cement can be of different grades: 50, 100, 200, 300, 400, 500, 600, 800. These numbers indicate the resistance of the material to the compressive force, expressed in kg / cm2.

- Lime. It can be used, quick, white, gray, etc. Strong, slowly hardening material, showing good performance in dry rooms. But not waterproof, poorly resists weathering.

- Gypsum. Quick-hardening material with low strength and poor resistance to moisture - quickly absorbs it, losing its properties. May be added to lime to accelerate setting, but is incompatible with cement.

Types of Solutions

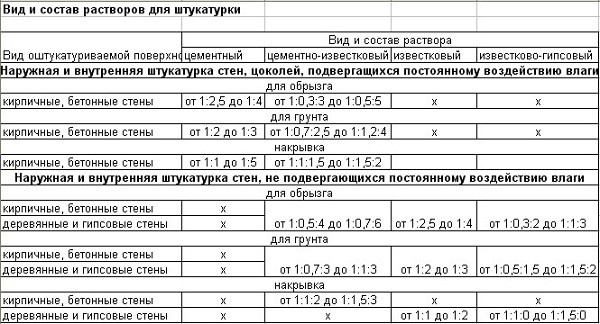

The composition of the plaster is selected depending on where and on which surfaces it will be applied.

This takes into account the above properties of the components:

- Lime (see We prepare ourselves a mortar for lime plaster). The proportions for the mortar of the plaster depend on the fat content of the lime test: two to five parts of sand are added to one part of it. First, these components are mixed in equal proportions, then water is added and mixed until lumps are eliminated, and then, if necessary, sand is added in portions to obtain a solution that resembles a viscous and thick dough in consistency.

- Lime and gypsum. In addition to sand and lime, gypsum is included in it, which accelerates the hardening of the solution and complicates the work with it, but the surface also acquires greater strength. Gypsum is usually taken one part to five parts lime.

Tip. If you are going to plaster with your own hands, remember that such a solution begins to harden in 5-6 minutes, therefore Cook it needs to be in small portions and quickly consumed.

- Lime-cement. Adding lime to a cement mortar increases its heat-saving properties. The ratio of cement-lime plaster may be different depending on its purpose. They are listed in the table below along with the proportions for other plasters. But you should know that lime absorbs moisture from the solution, therefore, to prevent its quick drying, the finished surface must be covered with a plastic film, otherwise cracks will appear on it.

Note. Lime significantly extends the setting time of the cement mortar, it can remain viable up to two days.

- Cement. This is the most commonly used plaster solution with a wide range of applications. They are decorated with facades and socles of buildings, walls in utility rooms, as well as in residential buildings, characterized by high or unstable air humidity (see. Let's consider how to plaster cement-sand mortar) It is worth telling about it in more detail.

What you need to know about cement plaster

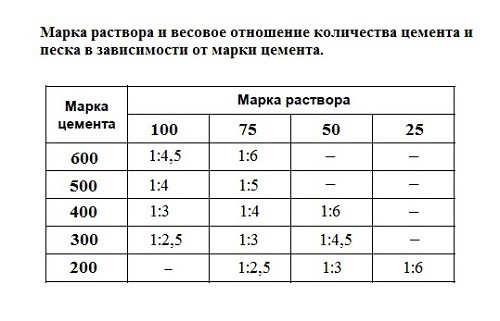

The main thing to remember: the proportions of water-cement-sand in the plaster depend primarily on the brand of cement. The higher it is, the less binder is required to prepare a solution of one brand.

As a rule, the instruction for the execution of a particular type of work contains information about what brand of plaster mortar is required in a particular case. The highest M100 is obtained by mixing one part of cement M400 and three parts of sand. The amount of sand decreases with increasing grade of cement and increases with its decrease.

Since the price of high-grade cement is higher than low, and sand is cheap or even mined independently on the banks of the rivers, to reduce costs while maintaining the required quality of plaster, it makes sense to buy a binder of the most popular grades M300 and M400, and not spend money on expensive material.

Failure to comply with the proportions leads to a change in the properties of the plaster:

- If there is too much cement in it (greasy solution), then when it dries, it will shrink strongly with the formation of cracks;

- If you shift the sand (lean solution), then the cracks, most likely, will not, but the coating will not have sufficient strength.

How to prepare a plaster mortar

Preparation of plaster - It’s also a difficult matter, it must be done according to the rules. If everything is clear with ready-made mixtures: they are simply poured with the right amount of water and mixed, then with self-production it is not so.

First you need to prepare the actual dry mixture, determining the proportions for the plastering of brick, concrete or other surfaces, taking into account their location (inside or outside, in a dry or wet room).

So:

- Dry components are poured into a mixing container. It can be a plastic, metal or wooden box with a smooth smooth bottom. And at first sand is poured, and on it in an even layer - binders.

- All ingredients are thoroughly mixed with a shovel or trowel, if the volume is small.

- Then the mixture is leveled and look at its color. It should be uniform, without streaks and stains of binder.

- If this is not the case, stirring is continued until a uniform color is obtained.

- Then the dry mixture is poured with water or milk of lime, allow it to soak and mix well. This can be done manually or using a construction mixer.

It is important that no lumps remain in the solution, and not mixed dry matter in the corners of the container. The viability of the solution depends on its composition.Cement-limestone “live” the longest, and you should try to use gypsum as soon as possible.

Conclusion

Not a single repair or construction is complete without building mixtures, and plaster is the most popular. If you know how to cook it correctly, then you will have no problems either with its application or with the quality of the finished surface. To get more useful information on this topic, we recommend watching the video in this article.