Plaster plaster Knauf

Knauf - A German company that produces building materials. One of the company's most sought after products is gypsum plaster. The range includes several finishes. Each material has a specific composition, characteristics and density. All this is recommended to consider when choosing a product.

The content of the article

Types of material by application method

Stucco plaster Knauf differs in the method of application. Allocate compositions for manual and machine use.

Composition for manual application

It is a dense mixture. The material is intended for applying a layer of up to 50 mm. This tool eliminates large differences, making the surface smooth, which improves the quality of the finish. The mixture cannot be used for machine application, as the product clogs the channels of the apparatus, which causes breakage. For this reason, the material is used manually.

Application Agent

In the company's lineup there is a special tool Knauf MP 75 gypsum plaster machine application. The material has moisture resistance, so it is used for finishing facades of structures, bathrooms, pools and other rooms with high humidity. Layer thickness - up to 20 mm. The material does not crack after solidification and does not deform during drying. Knauf MP 75 gypsum-based gypsum plaster evens the surface and makes the building base smooth, so the use of putty is not required for finishing. The material is intended for application on any surface. The tool will hold tight even on the old plaster. This guarantees a long operational period of decoration. The product is applied to the surface using a machine, can be used manually, but only by professionals.

Types of material

There are several types of Knauf gypsum plaster. Each of them has its own characteristics.

Rotband

Knauf Rotband - gypsum plaster, is in high demand among finishers. This is a universal product that is intended for surfaces of all kinds, including for heaters, for example, polystyrene foam. The material is used to align the walls and ceiling. The product has moisture resistance, therefore it is suitable for use in rooms with high humidity - kitchens, bathrooms. The product is intended only for interior decoration, so the material is not suitable for the facade. The price of plaster is 350 rubles per bag, weighing 30 kg.

The main element of the composition is gypsum stone. For elasticity and ductility, the product is complemented with other components.

Knauf gypsum plaster Rotband has the following advantages:

- cracks do not occur on the surface after solidification of the material even with a thick coating layer;

- vapor permeability, so the air circulates freely, which prevents the occurrence of mold and fungus;

- environmental friendliness - the material is safe for human health, and when it comes into contact with the skin does not cause irritation, because the composition does not contain harmful chemical compounds;

- fire resistance;

- the possibility of using for any type of construction base;

- surface leveling.

Material Specifications:

- shade - gray, white or pink;

- layer thickness - 5-30 mm;

- time of final solidification - 1 week;

- product consumption - 8.5 kg per 1 m2;

- bag packing - 5, 10, 30 kg.

Goldband

Gypsum plaster Knauf Goldband is intended for application on a solid surface - concrete, brick and other similar substrates. The tool is used only for leveling the walls, since there are no adhesive elements in the composition. If you use the material for the ceiling, this will lead to peeling and collapse of the finish.

The product evens out walls even with significant differences up to 50 mm. If the difference between the irregularities is greater, it is recommended to cut off such defects with a grinder, since a thickening of the plaster layer will lead to peeling of the material.

Goldband plaster resembles Rothband, but with more modest characteristics and reasonable cost. Price - 270 rubles per 30 kg.

Specifications:

- shade - gray, white or pink;

- layer thickness - 10-50 mm;

- time of final solidification - 1 week;

- product consumption - 8.5 kg per 1 m2;

- bag packing - 5, 10, 30 kg.

HP Start

Knauf gypsum plaster HP Start - a material for starting surface finishing. The tool eliminates differences in the construction base up to 15 mm. The product is used to align walls and ceilings. The composition is used for manual and machine application. For the latter option, the brand of funds MP 75 is used.

Specifications:

- layer thickness - 10-30 mm;

- time of final solidification - 1 week;

- product consumption - 10 kg per 1 m2;

- bag packing - 5, 10, 30 kg.

Rules for applying material

Knauf gypsum plaster is applied according to the rules, which are recommended to be carefully examined by lovers who finish their own hands.

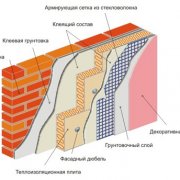

Surface preparation

The old finish is removed from the building base (as in the photo below). Further, oil stains, dust and other contaminants are removed from the surface. The main condition for the finish is a dry and clean base. Then the surface is primed. Knauf products are also recommended for this purpose.

Concrete contact is a primer that is used to prepare a solid base for plastering. The product can not be used for porous surfaces that absorb liquid. The product is applied to walls and ceilings, which are made of concrete or brick.

Grundirmittel is a primer that is used to treat porous surfaces - polystyrene foam, polystyrene and others.

The primer is applied to the construction base in two layers. After each treatment, a break is taken to dry the material.

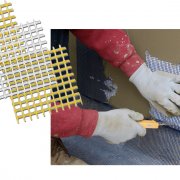

Beacon Installation

In order to level the surface qualitatively, it is recommended to install beacons in advance. First, profiles are fastened on the sides of the building base. Then the beacons are fixed over the entire surface area. The distance between the guides should be 20 cm less than the length of the rule.

Solution preparation

To prepare the solution, the dry mixture is diluted with water. Proportions indicate packaging. Then the composition is kneaded with a construction mixer until the consistency of thick sour cream. If it is not possible to achieve the material of the desired consistency, additional water or a dry mixture is added to the solution. When the product is ready, the product is left for 5 minutes. Then the solution is stirred and applied.

Material application

Instructions for applying the material:

- the solution is poured onto the surface with a trowel;

- the agent is distributed according to the rule;

- take a break to dry the composition;

- primed surface for better adhesion;

- work is suspended to dry the product;

- apply a second layer of plaster with a spatula and after drying the material proceed to the next stage of finishing.

How to align?

After the material has set with the surface, but until completely solidified, the surface is leveled. To do this, use a spatula or rule.The excess is removed, and the voids are filled with a solution. The irregularities that have formed in the corners and on the slopes are cut using a planer.

Smoothing and grouting

To remove stains from the spatula, the surface is cleaned with a felt grater. Before grouting, it is recommended to moisten the base with cold water. Grouting is carried out immediately after solidification of the material. Then the surface is primed and decoration is performed.

In the video in this article, the masters show how to properly use Knauf gypsum plaster.

The German company Knauf produces some of the best building materials. The quality of the products justifies the high cost of the products.