Foam facade plaster

Styrofoam Plaster - This is the stage of construction work to protect the insulation from aggressive manifestations of the environment and mechanical damage. Since the material, as a rule, is used for insulation from the outside of the building, then for plastering, you should choose a composition for outdoor work.

The content of the article

Which plaster is suitable for polystyrene foam?

Facade plaster on foam, first of all, must have reliable adhesion, since the insulation has a smooth surface. The tool must also satisfy the following requirement:

- moisture resistance, since the composition is used for outdoor work;

- resistance to temperature changes;

- vapor permeability, so as not to restrict air circulation;

- elasticity, so that the composition does not crack after hardening;

- strength to protect foam from damage.

Types of plaster

Front plasters for polystyrene foam:

- Mineral resources. They are dry mixes that require preparation. Such plasters are made on the basis of minerals, lime and white cement. Funds reliably adhere to the foam, protect the insulation from moisture, ultraviolet radiation and temperature changes. Another advantage is the low price. Disadvantages - short service life and the possible occurrence of cracks after drying.

- Acrylic compounds. They are finished products that are based on acrylic resins with mineral and other additives. Such products have increased strength, moisture resistance and frost resistance. The plaster is easy to apply and does not crack after drying. In addition, the composition improves the sound and thermal insulation of the foam. The service life of the coating of acrylic composition is 15-25 years. Cons of plaster - high price and color change under the influence of sunlight.

As a facade plaster for polystyrene, a cement-sand composition is sometimes used. However, professionals do not recommend this tool for insulation. Such plaster shrinks and cracks will appear on the surface within a year, which will necessitate repeated repairs.

Materials and Tools

To plaster the foam with your own hands, you will need:

- fiberglass mesh with a density of 140-160 g / m2;

- plaster;

- a primer;

- priming roller or brush;

- a set of spatulas for applying plaster;

- building grater;

- a clean bucket for preparing the solution;

- container for dosing the primer;

- industrial mixer or drill with mixer nozzle;

- plastic corners;

- construction knife.

Building foundation preparation

Instructions for preparing the surface:

- Fill the gaps between the joints of the insulation with foam. When the composition hardens, trim the uneven edges.

- Joints of polystyrene plates clean with a construction grater.

- Inspect material for bumps. If large differences are found, clean the defects.

- Set the head of the screws on the same level with the base. If the screw does not screw in, replace it.

- Process the foam with a needle roller (as in the photo below). This will improve its adhesion to the plaster.

Stucco technique

Plastering the foam is carried out in several stages, each of which requires careful study.

Solution preparation

Facade stucco on foam needs to be prepared only if a dry mix is used for work.

Place the composition in a clean bucket and dilute with water, temperature 200 C, in the proportions that manufacturers indicate on the packaging. Then, with a drill with a mixer nozzle or industrial mixer, knead the product so that the density of the solution reaches the consistency of thick sour cream. Leave to infuse for 5 minutes.

If a finished product is used for work, then after opening the package, the composition is stirred and used as intended.

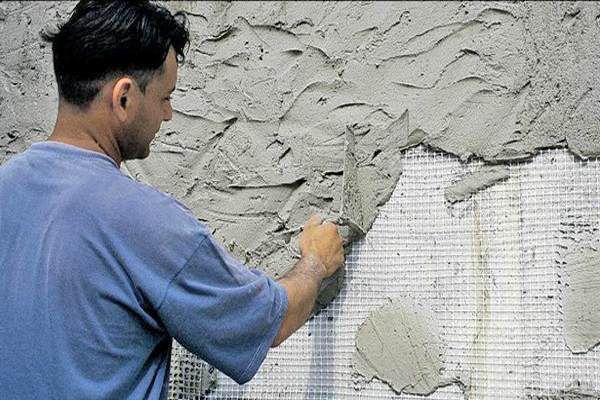

Styrofoam Reinforcement

Do not apply plaster without a fiberglass mesh, as the material will not hold onto the foam. Insulation reinforcement technique:

- cut the grid into pieces, 30 cm wide and fasten to plastic corners;

- apply the solution on both sides of the corners and slopes;

- attach a corner and press it and the grid into the plaster;

- swipe the grid with a spatula;

- apply another layer of solution;

- spread the composition on the surface;

- attach a mesh to the base and “drown” it in solution;

- swipe the surface with a spatula to level the grid and finally push it into the plaster;

- take a break in work for 24 hours to dry the solution;

- clean the surface with a construction grater;

- dust off the material;

- apply the primer in two layers with a break for drying.

Finishing plaster

Prepare a solution. The consistency of the composition should not be as thick as for reinforcement. Apply plaster to the surface. After a day, when the product hardens, treat the material with a construction grater. Sand the dust and apply the primer in two layers. After each treatment, take a break to dry the primer.

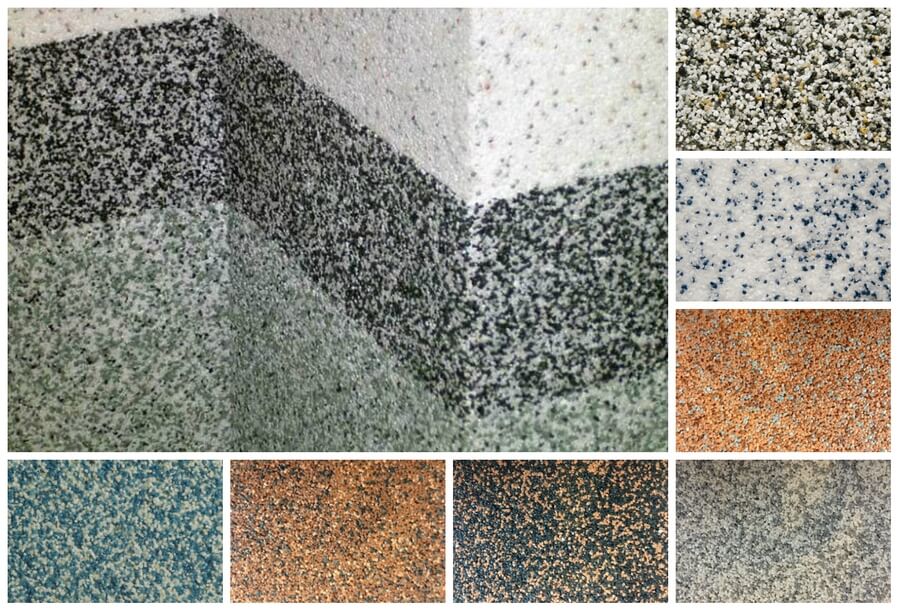

Decorative coating

Decorative facade plaster on the foam is applied immediately after the primer hardens. Use the finished composition immediately after opening the bucket, first prepare the dry mixture according to the instructions that are indicated on the package. Apply the solution on the walls with a spatula from the bottom up. Professionals recommend not having a break in work, otherwise there will be noticeable transitions on the surface or spots will appear. After applying the solution, form a relief. For this, masters are advised to use special rollers or graters. Spatulas or brushes with hard bristles are also used. After the formation of the relief, wait for the composition to dry and paint the facade. This will be the completion of the repair.

The video in this article demonstrates how to plaster foam.

If you know how to plaster a foam facade, you can do the work yourself and save on the payment of masters.