How to putty plasterboard walls correctly?

Plastering the walls of drywall - surface preparation before finishing. The application of this composition hides the irregularities of the seams and bonnet screws. Thanks to this, the surface will be flat, which will improve the appearance and facilitate the finish. The main thing is to choose a quality composition and know how to properly putty the walls of drywall.

The content of the article

Why apply putty on drywall?

The feasibility of puttying walls of drywall is not in doubt. This repair phase gives the following results:

- the composition protects the material from damage during the dismantling of the coating;

- the tool hides irregularities in the form of protruding hats from self-tapping screws and connecting seams;

- facilitates finishing.

How long does it take to work?

Puttying the walls with drywall with your own hands takes a maximum of two days, provided that the surface is uncomplicated relief. If the building base has niches, ledges, etc., then it will take more time to work. It will take three to four days. However, the duration of the putty on the walls depends on the drying rate of the materials used in the work. For example, if a primer is used that dries in 24 hours, the process will be delayed, since the composition is applied in several layers and the next step is not possible until the composition dries. Therefore, professionals are advised to choose quick-drying products.

Types of putty

Before you putty the walls of drywall, you should familiarize yourself with the types of composition.

The product is classified according to the sequence of application:

- Starting lineup. It contains fractions of large sizes, therefore it is used to eliminate surface defects. Recommended thickness is 5 mm.

- The finish tool. This is a fine-grained mixture. It is applied to the starting putty. Used to level the surface. Recommended thickness is 1 mm.

- Universal composition. It is used both as a starting and finishing means.

Putty is also divided by readiness for use:

- Ready mix. Available in sealed containers. The mixture is ready for use, therefore, does not need kneading. Advantages - easy to apply, disadvantages - high price.

- Dry mix. Sold in paper bags. The tool needs to be prepared. The composition is diluted with water and kneaded with a construction mixer. Advantages - affordable cost, disadvantages - without a special tool, the composition is difficult to prepare.

Plastering the walls of gypsum board is performed by cement, polymer or gypsum composition. Means are selected depending on the premises in which the work is carried out. In dry rooms, it is recommended to use a composition prepared on the basis of gypsum. In rooms with high humidity, putty is used with the content of polymers or cement.

Calculation of composition consumption

Putty consumption depends on the condition of the surface on which the composition is applied. The more damage on a building basis, the more money will be needed. The calculation of consumption also depends on the type of putty:

- 1.1 kg per 1 m2 - formula for cement compositions;

- 1 kg per 1 m2 - formula for gypsum products;

- 0.5 kg per 1 m2 - formula for adhesive.

Necessary tools and materials

To putty the walls of drywall, you will need materials and tools:

- capacity for the preparation of solutions;

- set of spatulas;

- construction mixer, if dry mix is used (a drill with a mixer nozzle can be used);

- grinding grater;

- reinforcing mesh;

- perforated corners;

- mounting knife;

- primer tool (brush, roller or spray);

- protective equipment (goggles and a respirator);

- primer;

- starting and finishing composition or universal tool.

Surface preparation

Filling the walls with drywall with your own hands begins with the preparation of the surface. All self-tapping heads should be 1 mm below the surface of the drywall. If inaccuracies are found, they are eliminated. The screws, whose hats rise above the base, are twisted, and the fasteners that are below the drywall are twisted. Next, the surface is checked for defects. On drywall - this is the departure of the sheets. If such a defect is found, the sheet is cut off and the surface is ground. If this is not done, then over time the putty will peel off along with the defect, which will necessitate updating the repair. Next is the priming of the walls.

For gypsum plasterboard surfaces, alkyd compounds cannot be used, since they destroy the material. It is recommended to use waterproof formulations of deep penetration. They are applied to the entire surface of the wall using a roller, as in the photo, as well as a brush or spray gun. The primer is applied in 2-3 layers. The drying time of the intermediate layers is 20 minutes. After the finish coat, work is suspended for the drying time indicated on the primer packaging.

Work algorithm

To understand how to putty drywall walls, you need to familiarize yourself with the algorithm of work.

Cooking composition

The finished product is used for its intended purpose immediately after opening the package. Cooking requires only a dry mixture. It is placed in a bucket and filled with water in the proportions indicated on the package. Next, the composition is mixed using a construction mixer.

Putty of tile joints

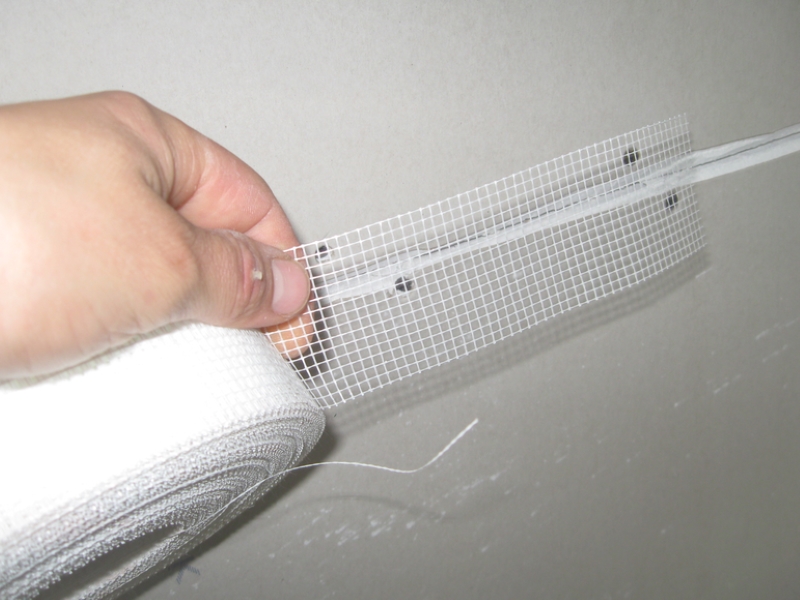

Putty joints begins with fixing serpyanka. It is recommended to use a self-adhesive reinforcing mesh. It is fixed on all drywall seams, as well as corners. Due to the fact that the adhesive is applied to the material, fixing to the wall will not cause problems. The mesh is glued so that the seam is exactly in the middle. If a non-adhesive serpyanka is used, then putty is first applied to the seam. After that, the serpentine is fixed on the composition and leveled with a spatula so that the mesh deepens into the composition. Then another layer of putty is applied on top of the mesh.

Corner processing

For corners it is recommended to use perforated corners. A layer of putty is applied to the surface. Immediately after this, a corner is fixed on it so that part of the composition seeps through the holes. The putty is evenly distributed with a spatula and another layer, 2 mm thick, is applied on top.

Putty of hats of self-tapping screws

The instruction for puttying the screws' heads is similar to the rules for applying the composition to the seams, but it has a difference. Fasteners are processed by the finishing composition with two strokes - along and across. After drying, the surface is polished.

Application of the composition to the main surfaces

When the putty is applied to all seams, corners and screws, you can proceed to the processing of the entire surface. For this, a finishing agent is used. This putty is distributed throughout the wall. Layer thickness - 1 mm.

Shutdown

The final stage of surface preparation before bleaching is the grinding of the building base. Before starting work put on protective equipment - glasses and a respirator.Next, the entire surface is treated with a grater. After that, a primer is applied to the walls and you can begin to finish.

The video in this article clearly demonstrates how to properly putty on drywall walls.

Plasterboard walls can be putty even by unprofessional craftsmen. To do this, you only need to carefully study the order of work.