Fiberglass for putty - purpose and installation rules

It is very disappointing when after a long and expensive repair is over, cracks suddenly appear on the ceiling or walls in those places where the joints between the sheets of drywall or other facing material pass. To prevent this from happening, experienced builders recommend not only confining themselves to a serpentine mesh for reinforcing seams, but to completely cover the surfaces with fiberglass with their own hands.

The content of the article

What is required for work

Gluing fiberglass is much simpler than wallpaper, it takes a little time, but you can have no doubt about the quality of decoration and that, due to shrinkage of the house or temperature changes, repairs will soon be needed again. Let's find out what kind of material it is, how it "works" and what it takes to assemble it.

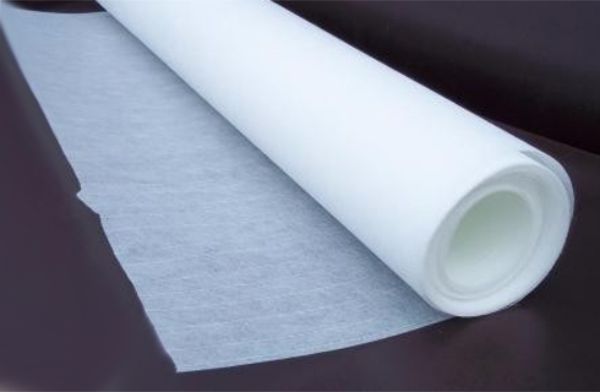

Fiberglass

Fiberglass is a non-woven fiberglass material that looks like a thin blotter. It is produced by pressing, rather than weaving the fibers. By itself, it does not have strength, it easily breaks, but after gluing to the surface, subject to strict adherence to the technology, it forms a reinforcing coating that is very resistant to deformation.

Fiberglass is sold in rolls of 45-50 meters with a width of 1 meter, and may vary in density. It has a front and back side, which must be taken into account during installation.

The price of the material is low, depending on the density of the roll can cost from 300 to 1000 rubles. This is not something to save on, as repeated repair as a result of cracking will be much more expensive.

Supporting materials and tools

Of course, the fiberglass itself will not stick to the wall, for this you need a special glue and a standard set of tools:

- Glue sometimes comes with fiberglass. If this is not the case, buy glue for glass wallpaper - no other, including PVA or a compound for heavy wallpaper, is suitable;

Note. When calculating the required amount of glue, multiply the consumption declared for cullet by 1.5-2, since fiberglass has high absorbency. In addition, the instruction requires that the adhesive be coated on top with already glued canvases.

- For applying glue, which has a rather thick consistency, it is best to use a wide brush-mowler on the surface;

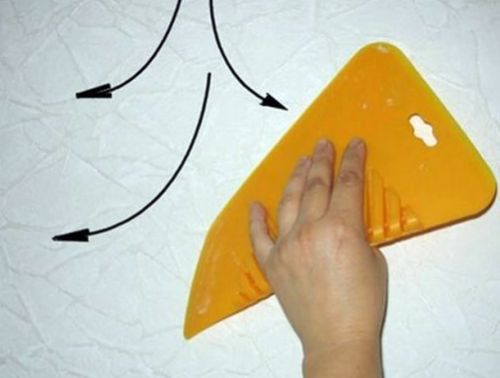

- It is convenient to smooth fiberglass with a special plastic wallpaper spatula, which experts call a “shark fin”;

- You will also need a sharp paint knife and a long ruler or a wide spatula for joining canvases and trimming overlaps.

Mounting technology

In the process of self-repair, many questions often arise.

In our case, the most important are the following:

- How to prepare a surface for fiberglass reinforcement;

- How to glue it correctly;

- Do I have to putty fiberglass before finish finish.

In this sequence we will answer.

Preparing walls for reinforcement

Before gluing fiberglass onto a wall or ceiling, the surface must be smoothed with putty (see Aligning the walls with putty in accordance with all the rules)This stage can be skipped only if it has already been puttied before, the coating is even and strong.

Small cracks with a thickness of not more than 1 mm are allowed.

- Large cracks on the plastered surface are embroidered and sealed in several steps with putty or a special composition for joints;

- Joints between sheets of drywall (see How to putty drywall joints according to technology) and other sheet cladding materials, as well as the places of their attachment to the frame, are also putty, and the seams are necessarily reinforced with a serpentine;

- After the patches have dried, the entire surface is smoothed with putty and polished until a flat surface is obtained;

Tip. Before applying a continuous layer of putty, mark on the drawing or specially made photographs where the seams go. When you start gluing fiberglass, they should not coincide with the lines of the joints of the paintings.

- Before gluing fiberglass, the walls are cleaned of dust with a vacuum cleaner and primed.

In short, all activities are similar to those held in preparation for wallpaper decoration. At this stage, it is very important to achieve almost perfect evenness of the walls so that the fiberglass lies on them without folds and tears.

Fiberglass sticking

First of all, measure the area of the pasted surfaces to determine the required amount of materials.

Tip. Keep in mind that fiberglass is lapped, so you need to add 5-10% to the data obtained.

You can buy ready-made glue, but it costs significantly more than dry mix. If you want to save, take the powder, but dilute it strictly according to the instructions from the manufacturer on the packaging.

Before grasping fiberglass, wear long-sleeved clothing with pants, a hat, and gloves. A respirator or gauze bandage will not interfere. The fact is that when working with this material, particles of fiberglass get into the air, which cause itching and sneezing.

Work execution order:

- Roll the roll and cut the sheets to the required length. In the case of pasting the walls, they will be equal to their height with a small overlap, and the ceiling is easier to finish with canvases one and a half to two meters long, especially if you work alone, without an assistant.

- Starting from the corner, brush a thick layer of glue on the wall with a strip a little more than a meter. You do not need to lubricate the entire surface immediately - the glue dries quickly.

- Glue the first sheet of fiberglass against the corner. First, gently press it with your hands, and then smooth along the entire length with a wallpaper spatula from the middle to the edges, as is usually done when gluing paper wallpaper.

- Excess canvas in the corner, on the floor or ceiling is trimmed with a paint knife in a ruler.

- Now, take the brush again and smear with glue the already pasted canvas on top, completely soaking it. Not smeared areas are easily calculated by color - they are lighter than the main surface.

- The second and subsequent paintings are glued in the same way, but with an overlap on the previous one. After leveling with a spatula and removing from the sheet of air and excess glue, a ruler is applied to the middle of the overlap and both canvases are cut with a knife on it. The trimmed strips of both sheets are removed, and the resulting joint is smeared with glue and pressed with a spatula in a longitudinal motion.

- When reaching the corner, measure the distance to it from the edge of the last glued strip and cut a piece of the appropriate width from the fiberglass, taking into account the overlap. The fact is that if the angle is not perfectly even, the material on it will still tear, so it is better to immediately make an even cut.

Thus, the whole area is glued. Do not forget to move the joints of the paintings relative to the joints between the sheets of drywall, otherwise a crack may appear at this point.

Before the walls completely dry, at least a day should pass, during which drafts should not be allowed in the room.

Finish finish

Finally, we will answer the last question: should fiberglass be puttied before painting, decorative plaster or wallpaper sticker.

It is necessary, at least for the following reasons:

- Wallpaper does not adhere well to such a surface, especially if it is heavy - vinyl or non-woven;

- The texture of fiberglass, not distinguished by decorativeness, will be visible under a layer of paint;

- The base reinforced with fiberglass is characterized by an increased ability to absorb moisture, which leads to a serious overspending of wallpaper glue or paint, which will have to be applied in several layers.

Therefore, it is advisable to putty the walls before the final stage of finishing with finely dispersed finishing compounds, having previously primed them. Since they were already aligned at the preparatory stage, it won’t take a lot of time and will not require a large consumption of materials: it is enough to apply 1-2 thin layers of finishing putty.

Conclusion

Gluing problematic surfaces with fiberglass several times reduces the likelihood of cracks on them, so its use is justified, and sometimes just necessary. How to do it right, you now know, but to consolidate the information we suggest you also watch the video in this article.