Looking to the future: a new building material - carbon concrete

Composite materials have not surprised either builders or customers for a long time. Everyone knows about their unique properties, their ability to withstand aggressive external factors is much better than traditional materials. However, life does not stand still, and every year new developments appear in this area.

One of them - coal-concrete - is worth telling in detail. About the idea of its creation, properties and prospects of implementation in construction.

The content of the article

Carbon fiber

Carbon fiber is a material that has long been known and in great demand in various fields of industrial production. But quite expensive.

The process of producing graphite filaments consists in multi-stage heating of polyacrylonitrile or viscose fibers in different media to the stage of carbonization. As a result, a material consisting of pure carbon appears.

Carbon fiber properties

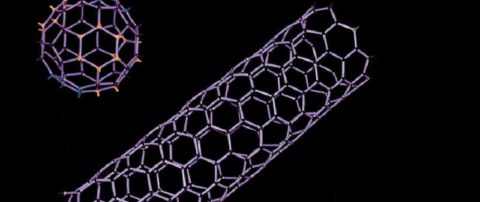

The thickness of the carbon fiber is only 5-10 microns, which is thinner than a human hair. It consists of chains of carbon atoms arranged in a crystal lattice.

- For the production of fibers, the threads are connected into bundles in which there can be up to 50,000.

- What properties of the material attracted attention and allowed to use it in the manufacture of structures operating in the most difficult operating conditions?

- First of all, it is a unique tensile strength. It is four times the same indicator for the best steel grades.

It is interesting. To break a 5 mm thick carbon fiber rod, a force of 2500 kg is required. Whereas the same cast iron rod will collapse at 150 kg.

The density of carbon fiber is four times lower than that of the same steel. Accordingly, the material weighs four times less.

Where is carbon fiber used?

Composite materials, in which carbon fiber is used as a reinforcing element, are used in machine and aircraft building, production of sports equipment, and construction.

We are interested in construction, therefore, let us dwell on this area of application:

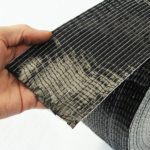

- Here, carbon fiber is the basis for reinforcing tapes, webs and even composite reinforcement for concrete structures.

- Ribbons and canvases made of graphite threads are a special weaving textile material impregnated with resins;

- Reinforcement is rods of carbon fibers impregnated with hardened polymer binder.

For reference. To ensure reliable adhesion to concrete, a sand coating is applied to the surface of the rods or protruding ribs are formed.

- Carbon fiber fittings

- Reinforcing frame made of composite rods

- Carbon fiber reinforcing mesh

- Grid reinforcement

Carbon fiber has a very high strength, so with its help reinforce new designs, or return lost characteristics to old ones.

All this has little to do with carbon concrete. But it was the special properties of carbon fiber that prompted German scientists to think of creating a new material.

What is coal concrete

So, scientists from the Dresden Institute for Monolithic Construction decided to replace the metal reinforcement in concrete with carbon fiber. Rather, the textile material obtained from it by weaving to obtain a special lattice structure.

As a result, they received material that literally in all respects surpasses all types of concrete known today. With much greater strength and lower specific gravity.

- Externally, the material differs little from traditional concrete

- Carbon concrete structure

- Carbon concrete building block

Despite the apparent simplicity of the invention, chemical scientists worked on it for several decades, ensuring that carbon fiber textiles reliably adhere to the concrete mixture. To do this, it is treated with a special coating, the composition of which is still kept secret by the manufacturer.

Technologies for the production of carbon concrete products

Currently, two methods for the production of carbon concrete products have been developed:

- A set of layers. The technology consists in layering textile fabric on concrete with subsequent pouring. That is, textiles are laid on the mixture layer, poured with a thin layer of concrete, and so on alternately until the required thickness is obtained.

- Pouring into the formwork. The traditional way is that in the formwork or form, carbon fiber reinforcement is first fixed, then the concrete mixture is poured.

Material benefits

When compared with reinforced concrete, carbon concrete gives the following advantages:

- It is much lighter, which facilitates and accelerates the construction;

- Coal concrete is several times stronger;

- It does not crack, and the reinforcement inside does not rust, while reinforced concrete begins to deteriorate over time precisely for this reason.

- As a result of the last two points, carbon concrete is much more durable and reliable than analogues with metal reinforcement.

The only minus of the material is its high cost. However, if we take into account that the structures made of it are extremely durable and do not require repair and reconstruction for many years, then this minus is compensated by the durability of operation.

Possible applications

To date, developers have already found application for this unique material. In particular, they used it to reconstruct old buildings of historical value in two German cities. Without their help, these buildings would have to be demolished.

In the future, it is planned to use carbon concrete in new construction. An experiment on the construction of a four-meter pavilion of complex elements with a thickness of 4 centimeters has already been conducted. It is impossible to build such a building from reinforced concrete, and it will not differ in the required strength.

Scientists even today receive requests from around the world, in which many reinforced concrete buildings need urgent reconstruction. They, in turn, hope that in ten years the ratio of carbon concrete and reinforced concrete used in construction will be 1: 4.