3D printing house building

In recent years, engineers in many countries - especially those where the population is growing too fast - have been working hard to create building printers that can be used to quickly and, most importantly, inexpensively build small houses. Why inexpensive? Yes, because the construction waste is used to create the mortar, which is crushed and mixed with cement. The cost of housing of 200 m2 is less than $ 5,000, and for the poor, this aspect is most important. We want to tell you a little about this technology.

The content of the article

The benefits of 3D construction

The creation of printing devices with which you can build cheap buildings, in parallel, engineers from different countries worked. But as always, the Chinese are ahead of the rest - their printer has the largest dimensions (32m * 11m * 7m). A year ago, on it, in just a day, 10 small houses (60 m2 each) were printed.

While no one lives in them, they are tested, observing how the structures will behave under the influence of the sun, wind and temperature changes. But the results have not yet disappointed anyone. In any case, it turned out that torrential rains and heat do not care for them. Therefore, countries with a warm climate were the first to build on this technology.

It is important

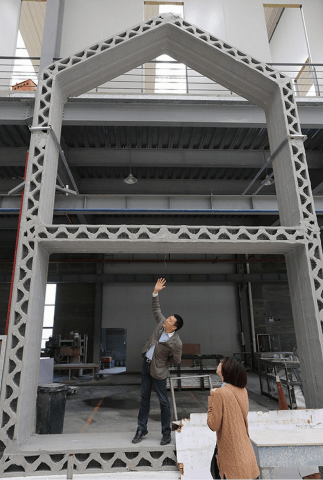

The creators of the largest printer, confirmed the quality of 3D construction on their own example. All the walls of the office of the company engaged in the development and promotion of this technology, located near Shanghai, are printed on a three-dimensional printer. The building has a total area of 10,000 m2, and its construction was completed in just 30 days.

- True, for this a conveyor of four cars was organized - but still, their performance is amazing. However, in Shanghai the subtropical climate, and the absolute winter minimum for it, is -9 degrees. Well, what will be the result of testing such structures in our frosts - this is another question.

- In any case, at such a pace and low prices, it is possible to solve housing problems not only in the poor provinces of China. What can I say - what is it worth to restore housing for people affected by all kinds of elements: fires, floods, hurricanes, earthquakes, from which no one is safe.

- For a person left without a roof over his head, even a plain home will seem like a paradise. There are enough people in need around the world, so many countries have shown interest in this technology: the United Arab Emirates, America, Italy, Holland, and, of course, Russia.

- Many of them developed printers of their own design, but by and large, they all function on the same principle. The creators of three-dimensional printing devices hope that as the technology improves, the price level of finished houses may drop even lower.

The main thing is that everyone saw and understood that it was good for people, and certainly not far off is the day when an even more powerful printer will be created that can increase the scale of the facility being built.

The essence of technology

As already mentioned, the capabilities of building printers are different. Some people can only print fragments of houses that are in a horizontal position. After gaining strength, the sections are lifted, mounted vertically, and connected together - which is what we see in the photo below.

But there is also an option that can print the house in a continuous way - that is, along the contour.In the future, this will enable construction companies with such equipment to travel with him to the address and build a house on the spot. We have no doubt that in the near future there will be combined machines that can do both.

- In addition, with the help of 3D printers, fiberglass reinforcement is also manufactured, which today is already in full use in low-rise construction. There is no doubt that the day is not far off when both options will work at the facility: one printer erects a concrete structure, and the second reinforces it.

- The essence of the technology is this: the configuration of a structure or building is set to the printer through a computer. A nozzle, from which a sufficiently thick and elastic solution leaves a continuous line, moves along a certain path - the contour of the future structure, increasing the height layer by layer.

- The walls are hollow, 30 cm thick. Their internal space is reinforced, filled with foam concrete - and it turns out not only a solid, but also a warm house.

In our country, they are working on this technology in Yaroslavl, where so far only small architectural forms are being printed at full speed: benches, arbors. However, they have already begun to build a residential building with a half-attic, an area of 80 m2. It does not promise to be as fast as the Chinese - after all, we do not have subtropics. Moreover, after all, the house needs not only to be built, but also to finish, connect communications. But by the summer of 2017, they plan to turn in the house, after which it will be possible to see photos of its facades and interiors. It remains a little, wait and see.

Business prospects

Performing a given program, a three-dimensional printer can work around the clock, and does not require any control and maintenance personnel. This fact will certainly be of interest to those who are looking for opportunities to create a new business. Despite the fact that the printer itself is not cheap, the growing popularity of houses built using 3D printing technology promises considerable benefits. Moreover, the lead time is incredibly compact.

For the printer to work, it is not necessary, like the Chinese, to use a composition based on cement and crushed building debris. It can be ordinary sand concrete based on Portland cement M500, or even adobe, which is used in the southern regions. For strength, the solution is reinforced with fiberglass, cellulose, or polymer fiber.

Note! Note that you can print on the printer walls, partitions, stairs, and even some elements of the foundation - but the roof will have to be done in traditional ways, because it is built not of concrete, but of wooden beams.

Taking into account the time required for laying communications and finishing work, a house of 200 squares can be rented out in a maximum of 6 months. However, it is difficult to indicate the exact cost of such a house. First of all, it will depend on the composition of the solution. It is not a fact that everyone will be able to process construction waste in such a way that they can be used as a filler. And then, the cost of roofing, decoration, windows, doors and communications, also varies.

Is it profitable?

Experts estimate that a house built using 3D printing technology, delivered on a turn-key basis, will cost about $ 20,000, which is half the size of a similar brick structure. Moreover, the quality of construction is much higher. This technology allows you to get the ideal geometry of the structure: the openings are even, there are no deviations either in the plane of the walls or in the corners. Accordingly, the surface does not need to be modified - and this is also a saving.

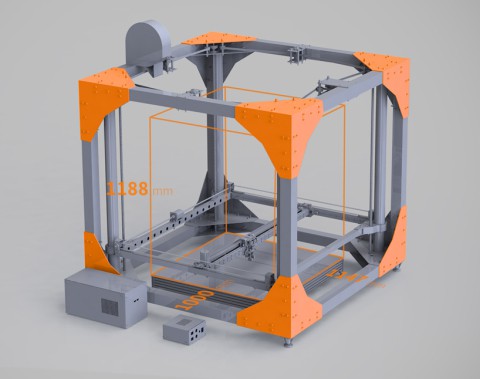

Today, three-dimensional construction printers are on sale.Small models for printing MAF and individual small-sized structures cost about $ 9,000. A device for large structures and monolithic buildings, already costs between $ 20,000 and $ 28,000. In fact, the cost of one house ready for use. But how much housing he can build! Given the cost of construction and the timing of their construction, the payback period of such a printer will be a maximum of 18 months.