DIY siding decoration: how to do it right

Do-it-yourself siding decoration at home is quite common. But it is not uncommon when a person makes mistakes that lead to a deterioration in the protective properties of the structure.

There are several reasons for this. There should always be instructions at hand and the work should be done correctly and in compliance with the necessary technologies.

This article will also tell you how to do the job correctly. Never rush to purchase material, first study the features of the installation and the rules of work.

The content of the article

Siding installation

Home decoration do-it-yourself siding is carried out according to certain rules, the observance of which will be the key to the correct installation and you will not regret what you did.

The right tool

For proper and continuous work, you will need to prepare a tool.

Then it will already be possible to start work:

- You will need a saw with a small tooth and a grinder. These tools do trim the panels;

- Screwdriver and screwdriver;

- Hammer;

- The hydraulic level with which we are roulette and the construction level;

- we will make the correct mi-quality markup;

Also, for the conduct of work, the site should be properly prepared. It will not work to perform the quality of the facing simply from the stairs.

You can do of course and a stepladder, in which a good place to stay. Only it will still be if you make temporary forests, then everything can be completed without problems.

Surface preparation

Do it yourself siding It starts from this moment. The durability of the structure and the observance of the correct geometric shape of the finish largely depend on the correctness of this work.

So:

- To begin with, everything should be removed from the facade, it can be shutters or other attachments. Nothing should interfere with the performance of the work;

- Now remove the old coating. To do this, use a brush for metal;

- We look at the wall and reveal the gaps between the frames of windows and doors. If they are, this should be eliminated. We make a cement mortar and use a spatula to process all the cracks;

- After that, we need to apply a primer on the surface, which is available on the market.

We do this with a brush or spray gun. We do the processing two times;

Do-it-yourself wall decoration with siding should have the correct configuration and have an ideal geometric shape. To do this, we need to correctly determine the plane of attachment.

We are not particularly interested in the base plane, we will need it to determine the correct mount finishing material.

So:

- We take the fishing line and pull along the diagonals of the room. Determine the base deviation of the wall surface.

When working, you should use a level that can help make the lining perpendicular to the plane of the earth; - Now we need to determine the installation start level. The fact is that the basement is especially not worth orienting; here the level of the land will distort the size.

We just put a mark on the wall where the fastening will begin;

Attention: When choosing the fastener start point, the dew point should also be considered.

The line should overlap the level of the floor. Otherwise, condensation will form and everything will go wrong.

- After marking, this size must be transferred to other walls. This is done using a hydraulic level.

It is worth buying or making it yourself. With the help of this non-tricky tool, work is done most efficiently. We transfer the size; - Now we need to combine all the risks in one solid line. For this, it is worth using a kapron thread.

Just hit the size. Now we have a plane attachment line and you can get to work.

Installation of the crate

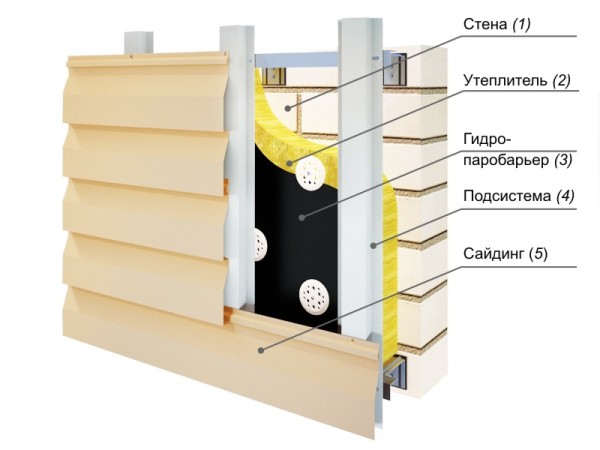

With your own hands, home decoration with siding is performed on the crate, which should be fastened with high quality and rigidly. The design has its own weight, which will be supported on it.

For its manufacture, a metal corner or wooden battens are used.

Immediately think about the insulation. The fact is that according to its thickness, the height of the frame should also be selected.

Mats should not be pressed against the lining, otherwise the structure of the material is violated and it loses its properties. Provide a gap between the panels and the insulation of at least one cm.

Attention: If you have chosen wooden slats, then you need to do their processing in advance and prepare everything. The material should be treated with antiseptics that are commercially available. And then let them dry completely. Apply a couple of times. This will significantly extend the life of all wood.

You can mount on any of the proposed materials. It all depends on your desire, but, of course, the metal corner will be much more reliable and will last much longer.

So:

- Now cut the material to the desired size and fasten it to the lower level of laying. This is done strictly along the drawn line.

For a wooden surface, a wood screw is perfect. If the plane is concrete or brick, then a perforator should be used.

First, a hole is made and after that we make a connection to the dowels.

Caution: Do not use the wall plugs from the kits. They will not give a reliable connection. Obtain separately plastic and self-tapping screws to it.

Only oh diameter should be foreseen a couple of mm more from the hole section. It is this connection that will ensure the reliability of fastening.

- Now we make the same binding of the room along the upper part. When attaching, the installation height must also be observed.

Adjustment is carried out with the help of gaskets, which should be installed under the profile or go wooden rail; - After installation, we mount the transverse rails. The siding should be fixed perpendicular to the battens.

We cut off the material and fasten, as described above. We apply gaskets and do height adjustment.

After installing the battens, you can conduct insulation of the room. Mats should be fastened tightly to each other, but not to bend and deform.

The connection is made using plastic fungi. Fastening one mat is done at least five points.

Siding installation

Home decoration siding do-it-yourself videos you can watch on our website.

This work is done as follows:

Caution: When installing siding, special attention should be paid to waterproofing. If this is not done, then there will be condensation.

It should be installed even if you do not use insulation.

- First of all, we do the installation of hydraulic oil. It must be fixed rigidly and strictly along the installation line;

- Now, after installing the battens, you should mount the waterproofing. First, we cut off the material and fix it.

Just do it tightly. Consider bending the material onto the rails and fasten with a stapler.

There is another way. This is the installation before fixing the battens.

Only there is its inconvenience. It’s a little difficult to mount on the wall, but here you choose the way.

Do as conveniently. We fasten waterproofing; - Now do the installation of the angular profile. It must be attached extremely rigidly and securely. He will hold the panels and guide them.

It has special holes for mounting. And therefore, the connection should be done strictly through them.

If you do not have enough length of the element, then the next one is cut to the desired size and the fastening is done with an overlap on the first. It is an overlap. This will prevent water from flowing; - Now do the fastening of the starting strip. It will determine the direction of installation of the elements.

We make its installation about 5 mm lower from the edge of the corner profile;

- Now do the trim around the windows and doors. This is done using special strips or using a J - profile.

The lower outer edge should be set a couple cm lower with respect to the inner. When performing angles, the profile should be cut at an angle of 45 degrees and make the correct angle when making the connection; - For metal construction, an H profile is used for vertical installation. When fastening, the construction level should be applied and the installation should be perpendicular to the ground.

It is also necessary to provide for a gap with respect to the base and the cornice of the order of one cm. This will prevent troubles when expanding the material; - Now, under the roof, we fasten the finish strip.

Cladding siding

This is a responsible question that completely determines the appearance. Therefore, the installation must be done according to certain rules that must be followed.

So:

- Panels cannot be fixed rigidly. A small clearance should be provided to prevent the effects of expansion.

With a change in temperature, fluctuations in the dimensions of the part fluctuate within 1%, it is for this reason that the mounting grooves have a gap within this error. The connection is made only in the middle of this hole.

You can’t just drive in nails, then the panel will only drive; - Also provide one cm clearance between the rails and the slats. If you are doing the installation in hot weather, then this size should be reduced.

When the temperature decreases, the panel will simply decrease, this should be considered.

Attention: Mounting is done in any weather.

It is only worth knowing that if the temperature is below -10, then the material begins to crack when cut. Therefore, this work should be done very carefully and it is advisable to use a grinder for this.

- We begin fastening the first panel, which is connected to the starting bar. Fixation is determined by clicking, this is a signal that the panel has become in place and it has been fixed in the groove.

Fastening is carried out in special holes every 40 cm. This is how fastening is done to the very top; - If you use metal scissors for cutting, then use only ¾ of the blade length for cutting. Only then will the cut line be smooth and of high quality and the material will not bite;

- When using a knife, do not try to make a complete cut, it is a laborious job. Just make an incision and after that just break the material.

The edge then simply needs to be processed with a sharp knife; - Fasteners should be used so that the penetration into the surface of the crate is not less than 35 mm. And you should never bend the mount.

This creates excessive stress in the panel and this can lead to deformation of the material; - Never drive or screw fasteners through vinyl. If there is a need to make the mount in the wrong place, then you should make the size of the hole with the tolerance that is provided for in the panel and only then make the mount;

- The panels are fastened only from the middle and towards the edges. And in no other way;

Attention: When fastening two panels horizontally, a gap should be provided, which should be equal to the width of the temperature gap and multiplied by two. There is a principle, two widths suggest two gaps.

- When joining the panels, overlap should also be provided, this is the standard value, which is 25 cm. This is done so that the snow does not clog and moisture does not penetrate during the rain.

Now you have instructions and recommendations for doing this work. It is worth looking at the photo and deciding on the design of the finish and you can begin to do the work.

The most important thing is not to rush. Make proper markings and monitor quality fastening.

All work can be done completely with your own hands and without resorting to outside help. The most important thing is to treat her correctly.