How do I do wall sheathing with plastic panels myself

How to sheathe plastic wall panels? If there are unevenness, potholes, or hard-to-remove mold areas on the walls that are difficult to remove from surfaces with plaster and putty, the most rational solution is to finish the walls yourself with plastic panels.

A properly installed wall frame allows you to make the coating perfectly even, get a solid plane, mask all defects. How to do this correctly will tell the article.

The content of the article

Features of wall cladding with plastic panels

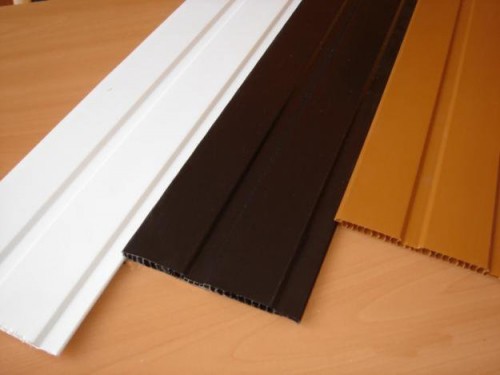

Wall plastic panels are products made from polyvinyl chloride (PVC) by extrusion.

In this process:

- The molten dense mass of the composition on special equipment is extruded through the diecorresponding in shape to the profile of the panels.

- Workpieces are cooled at a certain temperature.

- Cut to the required size.

- Standard panel thickness is:

- 5 millimeters;

- from 8 to 10 millimeters. Despite fluctuations in thickness, this is a single standard size; for it, components, such as moldings, are made the same.

- The width of the plastic sheets for wall decoration ranges from 20 to 37 centimeters - This is a fairly wide plastic panel for the walls.

- Standard element length:

- 2.6 meters;

- 2.7 meters;

- 3 meters.

The advantages of PVC panels are:

- Safety. Do not emit harmful elements when heated to a temperature (+ 80 ° C).

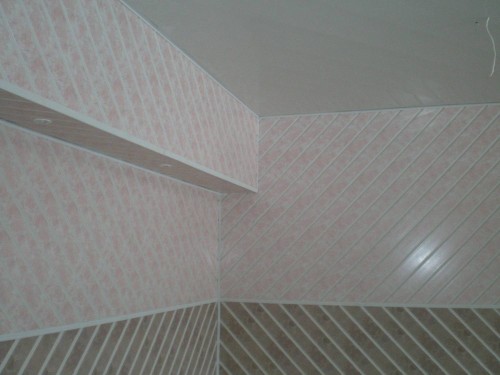

- Aesthetics. The lack of seams at the joints, a variety of colors and patterns. On the PVC panel, you can apply thermal images to photo images, paint them, decorate with a self-adhesive film. This allows you to use the material:

- in the bathroom (see Covering the bath with plastic panels: do it right);

- loggias (see Finishing the loggia with PVC panels: installation instructions);

- living room.

Separate panels are sheathed walls in the bedroom for adults.

- Durability, over 10 years, and high resistance, despite the dampness in the bathroom and temperature fluctuations on the balcony.

- Practicalityease of maintenance. It is sufficient to periodically remove dust.

Along with this, PVC paneling has a number of disadvantages, which are due to the chemical composition and properties of the material.

These include:

- Low hygiene. Plastic does not breathe, it does not let in steam, which requires restrictions on its use in the bedroom. The kitchen should be well ventilated and have a powerful hood in the room to remove fumes and soot. Glare from the glossy surface from sunlight and polarization adversely affects the psyche of the child.

Tip: You can’t decorate a children's bedroom with plastic glossy panels.

- Toxicity on burning. When ignited, PVC actively burns with the release of gases with very serious consequences. Because of this, the kitchen is not completely sheathed with plastic panels: in the risk zone is a section of the wall above the gas stove. Finishing should not have contacts with wiring, heating, lamp housings.

What elements are needed for mounting panels

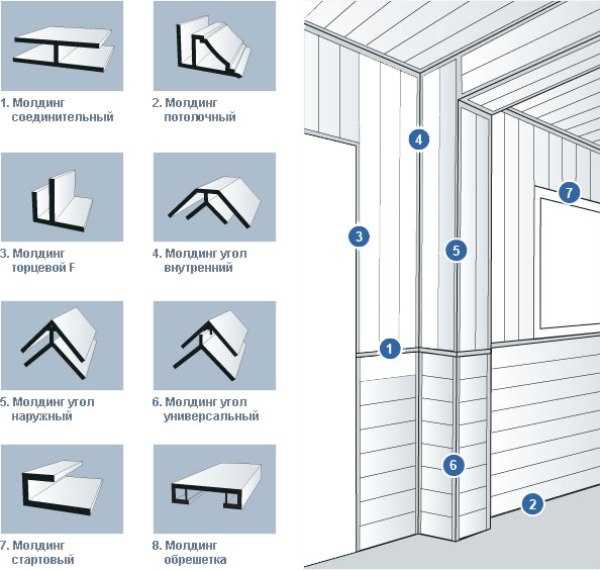

Before sheathing the walls with plastic panels, it is necessary to purchase additional moldings - fixing and at the same time decorative elements that give the lining the final look. Profiles are of several types, shown in the photo.

They may be:

- Starting.

- The finish.

- Guides: upper and lower. These are installation moldings that create a frame around the entire perimeter of the trimmed plane.

- Corner exterior. With its help, protruding corners of the room are formed.

- Corner internal, mounted along the internal corners.

- Connecting. Designed for the end connection of elements, with the combined decoration of panels of different colors.

- Skirting boards or fillets. Are fixed on glue.

- Simple corners. Used for finishing corners, glued to the skin.

The panels are attached to the wooden frame with brackets and a construction stapler, to the metal one - with self-tapping screws.

Tip: Polyvinyl chloride is characterized by a high coefficient of thermal expansion, it follows that during installation, fasteners must be made with a small gap for elastic deformation of the plastic panel. At the same time, the brackets make it possible to move the plastic, but the “flea” self-tapping screws do not. In this case, thermowells consisting of a sealing ring, a cover and a washer with a foot must be used with self-tapping screws. A gap of at least 1.5 millimeters should remain between the wall of the hole in the plastic and the leg of the washer.

Before lining the walls with plastic panels, the video-lesson will tell you the nuances of the work.

How to make a crate for panels

Plastic wall cladding begins with the manufacture of a frame for panels or wall battens. This will allow in the future to quickly replace, if necessary, plastic panels and securely fasten them.

For crates are used:

- Wood Bars.

- The metal profile is less common.

At the same time, small cells located behind the structure can be used for laying insulating materials. On the wall surface, the crate is fastened with clamps or self-tapping screws in the dowels.

Lathing fasteners are installed in increments of up to 0.5 meters. The distance between the bars is chosen so that the laying of the insulating material is as simple as possible.

How to install PVC panels

One of the main features of the material is ease of installation.

Wherein:

- Plastic panels for walls, their wide mounting shelves are fixed to the crate with brackets or self-tapping screws.

- On the other side of the part there is a small mounting shelf hanging over the crate.

Before sheathing the walls with plastic, the necessary tools are purchased:

- Jigsaw, to adjust the size of the mounted elements.

- Construction stapler for attaching plastic fragments to the wood crate.

- The miter box, for reliable fixing of the tool when cutting panels.

- Stucco spatula, to facilitate the bending of part of the finishing profile.

- Rubber mallet helps to easily pull the panel in place.

Installation instructions for plastic panels after the crate:

- Profiles are installed:

- guides;

- starting;

- finish.

- The first sheet of the panel is installed in the lower profile, the element is bent by an arc and installed in the upper profile.

- With a mallet, the sheet is pressed firmly against the start profile.

- Other plastic elements are fastened in the same order except the last.

Tip: When mounting the remaining element, you should be very careful.

- The last panel is trimmed from the side of the large shelf for fasteners. A small margin is being made for its expansion.

- The finish profile panel is unbent, the lower part of the last element is installed so that it fits tightly into the profile. For this:

- part of the finish element is allocated;

- the panel winds up to the upper corner;

- shelves of finishing and assembly profiles are unbent, and a plastic fragment is finally fixed.

- The panel and finish profile are attached to the crate with a construction stapler.

- Plinths are arranged.

How to glue PVC panels

In this way, smooth, dry surfaces can be finished.

Wherein:

- There should be no dust, dirt or grease stains on the surface.

- Special glue is used - “liquid nails”. Do not use glue containing cleaners or solvents.

- When covering the shower wall, a gap of up to three millimeters is left from below, to prevent a “rush” of material when the pan expands.

- The joints must be filled with silicone sealant.

How to care for panels

Plastic care is quite simple:

- Wash the panels with a soft cloth

- Use special detergents that do not contain solvents or abrasive particles. Most often, enough ordinary soapy water.

- At the end, the surface is washed with plain clean water.

How we sheathe the walls with plastic panels can be seen in the video in this article. Cladding walls with plastic panels is an excellent option, helping to save enough money and make the room comfortable. The price of PVC panels in the repair of rooms and wall decoration is very different, there is always the opportunity to choose the best option that satisfies the quality and cost.