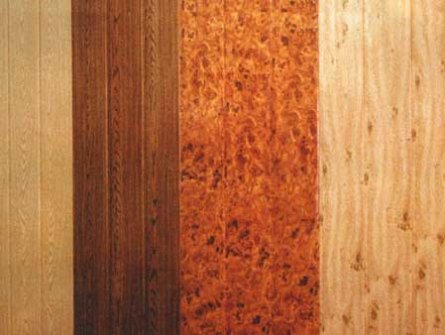

Facing MDF panels of walls and ceilings

If you are looking for an inexpensive, but highly decorative finishing material that is safe for indoor use, pay attention to MDF panels. They became very popular not only because of these characteristics - consumers appreciated the ease of installation of panels, which any person who knows how to hold a hammer and a jigsaw can handle on their own.

The content of the article

What are MDF panels

The Russian abbreviation MDF (fine fraction) is similar in sound to the English MDF (Medium Density Fibreboard). The German name for the material is HDM.

On sale, you may come across such panels with any of these designations, depending on the manufacturer. What is facing panels from MDF?

Description of the material and its characteristics

Unlike the long-known fiberboard (wood-fiber board) and particleboard (wood-particle board), this material does not contain synthetic binder resins that release harmful substances into the surrounding space. Therefore, it is absolutely safe for the health of people who are constantly in a room decorated with MDF.

It is produced by hot pressing of the smallest wood fibers, which are tightly glued to each other under the influence of high temperature and pressure. In this case, the binder becomes lignin, which is part of any wood.

The material obtained in this way has all the positive and negative properties of natural wood.

The first include:

- Ecological cleanliness;

- The ability to "breathe";

- Excellent heat and sound insulation characteristics, etc.

However, it burns no worse than a tree, and it is even more sensitive to moisture, quickly starting to deform, warp and mold.

Attention! Wall cladding with MDF panels is allowed only in indoor heated and dry rooms.

The positive features of the material include the ideal geometric shape, a large selection of front decor and ease of processing and installation, which is ensured by a special profile of the edges forming a tight castle connection.

The price deserves special mention - it is much lower than that of natural wood panels similar size and good quality. At the same time, paneling does not require additional processing after installation - coating with varnish or tinted impregnation. The material does not dry out and does not crack over time, bugs do not start in it.

Application area

MDF panels are a material exclusively for interior decoration of walls and ceilings. Although the laminated film covering it protects the panels well from moisture, not passing it to the base.

In addition to walling, the industry also produces special door panels that are even better protected from moisture and mechanical damage. They can be finished with PVC film, natural or artificial veneer, plastic.

The outer lining of the doors with MDF panels allows you to update the old wooden or decorate the metal entrance door, while increasing its heat and sound insulation properties.

Large thickness MDF boards are also used today for the manufacture of furniture, mainly for children and kitchen.

Panel Mounting

For the installation work, you will need the simplest tools: a plumb or level, a hammer, a screwdriver, an electric jigsaw, a construction corner and a pencil.

Wall Cladding Technology MDF panels consists in creating a leveling surface of the frame and its casing. Often when decorating ceilings and walls facing the street, frame cells are used to install heat-insulating materials in them - polystyrene foam, sheets of stone wool, etc.

This technique allows not only to reduce the intensity of the outflow of heat from the room in winter and its influx from the outside in the summer, but also protects the panels from condensation.

Tip. If insulation or soundproofing is not required, and the mounting surface is fairly flat, the instruction allows gluing MDF to it on any wood glue or “liquid nails” filled with fine wood sawdust. The color of the glue can be matched to the tone of the decorative coating, so that in case of accidental contact with the front surface it does not leave visible marks.

Frame device

The frame can be assembled from wooden bars with a cross section of about 20x50 mm or metal profiles.

Each option has its advantages and disadvantages:

- Technology paneling MDF on a wooden frame is simpler - they are simply nailed to the bars with small cloves. But the tree requires preliminary impregnation with special antiseptic additives, it must be dry so that the bars do not “lead” when dried.

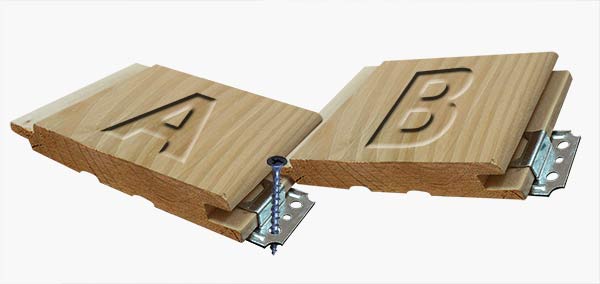

- The metal profiles are perfectly flat, which simplifies the installation of the frame in terms of level, and more durable. But for mounting panels on them, special klyimers and metal screws will be required, and this complicates the work and requires more time to complete it. But if necessary, it will be easier to dismantle the casing, and the panels will remain intact.

Decide for yourself what is more important for you - simplicity and speed or reliability and durability.

The frame should be a guide located in the same vertical plane. They are mounted parallel to each other with a step of 45-50 cm in the direction perpendicular to the location of the decorative panels.

As a rule, they are installed vertically, so the frame rails are horizontal.

How to mount a wireframe is a topic for another discussion, and it has already been touched on more than once in other materials on the site. We only recall that it is easiest to install it by level, using mounting brackets that are attached to the base with self-tapping screws or plastic dowels and screws, depending on the material of the walls or ceiling.

Attention! Regardless of the direction of installation of the frame, when facing the walls, one rail should be fixed along the floor line. It is needed for subsequent mounting of the skirting board.

Paneling the frame

After mounting the frame and checking the correctness of its level begins wall covering MDF panels - the installation technology is extremely simple and understandable, to cope with it is much easier than with the previous stage.

So:

- Measure the height of the room (with the vertical installation of the panels) and cut the MDF along the length using a building corner and a jigsaw;

- Install the first panel in the corner from which you begin the installation, the side on which the tongue is located;

- On the side of the tongue, stepping back from it a few millimeters, fasten it to the frame with cloves or small screws (if the frame is metal);

- From the side of the groove, the panel is nailed to the wooden crate with small cloves.If the frame is metal, then a kleimer is put on it, which is screwed to the profile with self-tapping screws.

This method can also be applied to a wooden frame if you want to facilitate dismantling in the future and maintain the integrity of the cladding;

- The next panel is pushed all the way into the groove already installed with a tongue and groove, and is fastened, as described above, only from the side of the groove;

- The last in the row corner panel, if necessary, must be reduced in width, inserted into the penultimate one and fasten the free edge with studs or self-tapping screws.

Thus, all walls are sheathed. For ease of installation of the latter in a series of panels, they can be made several millimeters narrower than necessary - the joints will be closed with a border.

You can fully explore this process on the video posted on this page.

Edging

To mask and decorate the internal and external corner joints, niches, openings, special trims and corners from the same material are used.

Corners can be bent in any direction, so there will be no problems with their installation. They are glued to the panels with transparent silicone sealant or “liquid nails”.

Conclusion

As you can see, MDF panels have a lot of advantages, one of which, undoubtedly, can be considered the ease of installation, which anyone can do with their own hands. They allow you to implement various design solutions with minimal cost of finance, time and labor.