Paint for a metal fence: which one to choose

A metal fence is always stylish, practical and durable. And in fact, what could happen to iron? After all, he is not afraid of any natural influences. This is not so, the metal is very afraid of water, and it must be carefully protected from it.

In this article we will talk about what a high-quality paint for a metal fence should be, so as not to update it every year.

The content of the article

Blacksmith paint

As the name implies, this paint was originally designed for metal, and today is one of the best materials for corrosion protection. Only powder polymer can compete in quality and durability with blacksmith paint, but in contrast to it, blacksmith enamel can be applied to the fence yourself, and you don’t need special equipment or any specific skills.

In order to immediately set the tone for the article, we will not describe the qualitative characteristics and praise some material. Just describe a few characteristic features that you need and it is important to know, choosing what to paint the metal fence.

And how to do this will tell the video in this article, which describes the entire process in detail. So, let's begin.

Features of blacksmith paint that you need to know about

So:

- After drying, on a painted surface, you can safely bang with a hammer or drive with sharp objects. There will not be the slightest trace.

- No environmental impacts, metal, even, can be under water, and that coating will last several years.

- The quality of the coating is guaranteed only when used together with the same grade of soil.. Of course, you can try experimenting, but if the coating peels off after a few years, it will no longer be the fault of the manufacturer.

- The cost of painting a metal fence with blacksmith paint can often exceed the cost of the fence itself. Price is the main and most significant drawback of this enamel. Although if you think about it, then a material with such characteristics, by definition, can not be cheap.

- The paint dries very quickly, each layer is not more than an hour, at room temperature, which can also be attributed to positive qualities.

Simply put, if you choose which paint is best to paint a metal fence, and plan to do it yourself, then you will not find better material, well, provided, of course, that you are ready to pay a decent amount for several cans of paint, soil and a special solvent.

Advice! The instruction on the can of blacksmith paint suggests that even the solvent should be of the same brand. From personal experience, we can say that this is not just an advertising move and a way to sell your products. Paint, of course, interacts with solvents of other brands, but you can forget about the characteristic gloss.

Powder polymer

From the very beginning, it should be noted that self-painting of a metal fence with powder polymer is simply impossible. Unless, of course, you have special equipment in your garage.

Yes, an ordinary brush or even an airbrush can not do here.To work with powder dyes, you need not only a special spray gun, but also a polymerization chamber (see Do-it-yourself powder paint oven), in which the metal is heated.

The principle of powder coating is to apply the paint by magnetic induction, that is, the spray gun has a positive electric charge, and the product itself is negative. As a result of the collision of charged particles, the molecules of the paint penetrate the very structure of the metal, as if becoming one with it.

After applying the paint, the product is placed in the polymerization chamber, and is heated to a temperature of 200 degrees. As a result, final sintering occurs, and the resulting coating is almost impossible to remove. In quality and durability, such a coating is ahead of blacksmith paint, both in quality and price.

Features

So:

- Extremely high resistance to all types of natural aggression. The paint is not afraid of either rain or snow, and even salt water is not able to harm the coating.

- The polymer does not fade under the influence of ultraviolet radiation and does not lose its qualities. The gloss of the coating will remain even after 10 years. And all that is needed is to wipe the product from adhering dust and dirt from time to time.

- A significant minus of the polymer coating is that if you are tired of the color and you decide to repaint your fence, it will be very, very difficult to do, and independently and without a special abrasive tool is completely impossible.

- Do not apply a layer of other paint over the polymer coating. They simply will not have adhesion, and it will immediately come off.

Surely many now have a question, how much does it cost to paint a metal fence with powder polymer. We will not be able to answer it, since it all depends on the complexity of the product and the prices of the masters, but remember that such a coating simply can not be cheap.

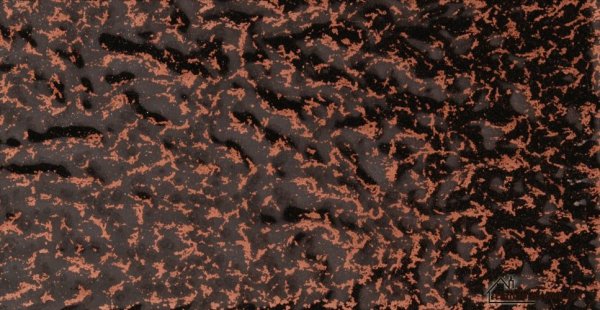

Important! Externally, the powder coating is very similar to hammer enamel, which will be discussed below, and which is significantly inferior to the polymer in quality. Some unscrupulous painters give out enamel for a polymer coating, and you will feel the difference only after a few years, when the grief of specialists has already cleared up. Therefore, if you are offered a polymer coating at an amazingly low price, this is an occasion to think.

Hammer enamel

As we already said, outwardly hammer paint is very similar to polymer, but naturally, inferior to it in quality. Although, if we were rating paints for metalBased on their qualitative characteristics, hammer enamel would certainly have received the third place.

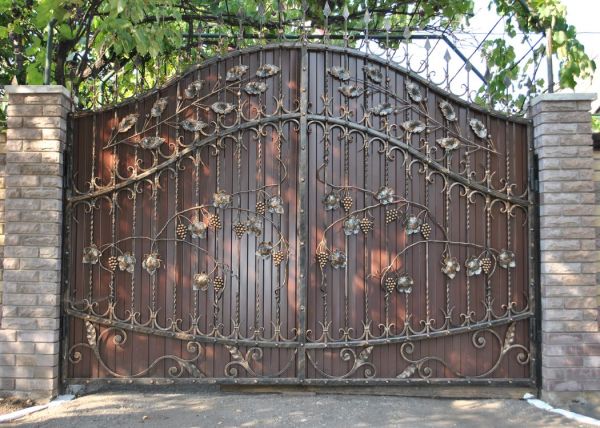

It acquired its name due to the peculiar effect of the coating, which visually resembles the potholes left by the blacksmith's hammer. This effect not only looks attractive, but also is able to hide some metal defects that often appear on products during production.

Hammer paint can be applied to the surface in any convenient way, but experts still advise working with a brush or roller. In this way, the paint layer is thicker, and therefore there will be no gaps, and the effect will manifest itself even more.

You can certainly simplify the task and use a spray gun, but it is important to remember that even after dilution, the hammer enamel remains very thick and viscous, which means that the pressure under it must be adjusted separately. And by the way, an electric spray gun will not work here, since they do not have enough power to work with such thick materials.

Features

So:

- Holding on hammer paint it is very durable and damaging the coating is not easy, but this is often the drawback, since if you need to repaint the product, you will have to remove the old coating, and here you will need not only a special tool, but also a wash for hammer enamels.

- In the process of dyeing products of complex configuration, in some places necrosis can form, and it is there that the corrosion process will begin. Rust will gradually move on, and the product will lose its appearance, so you need to follow this very, very carefully.

- To work with hammer paint, it is unnecessary to prime the product, and moreover, it is strictly forbidden. Enamel does not interact with other types of paints, and when applied to the old layer, it simply curls up. Therefore, the product may be in oil and grease stains, but you will have to carefully discard the old paint.

The main difference between polymer powder and hammer enamel is the very process of polymerization, during which the paint melts and fills all inaccessible places. It is very convenient, and with hammer enamel, this issue will have to be solved independently.

Pentaphthalic Enamel

In the people, this paint is most often called just oil, or abbreviated PF. A few dozen years ago, in our country, there simply was no alternative to her, which is why she received such wide distribution and popularity, which are still present.

But today, in the age of high technology and new paints and varnishes, PF enamel has rolled far in the ranking, and has become the essence of the most poor-quality paint. For example, in comparison with the paints that we described above, it does not go into any comparison, and from the significant advantages we can distinguish, perhaps, low cost.

Painting the fence made of metal PF enamel (see The better to dilute the paint pf 115), the most short-lived, and in the best case, such coverage will last 5 years, and this provided that you give preference to an eminent brand, the price of which will also bite.

Basically, such a coating can withstand in the conditions of the street for one year, after which the paint loses all its qualities and begins to climb. In winter, it is fatally affected by humidity, and in summer, ultraviolet rays. Under their action, the coating quickly burns out and begins to peel off, which means that the product will have to be updated again and again.

Features

- Before painting the PF metal fence with enamel, it must be cleaned, degreased and primed. Only in this way can paint be used for at least several years. If you skip one of the stages, get ready for the fact that the coating will begin to lose its quality in a few months.

- Enamel can be applied in any way, but an airbrush is still preferable, since the brush and roller will leave behind themselves traces that will remain on the product. The spray gun, of course, is less economical, since a lot of paint just flies into the atmosphere, but the layer is even and without flaws.

- In no case should you mix enamel on an oil and nitro basis. When in contact, they come into conflict and simply collapse.

Important! When working with a spray gun, be sure to use personal protective equipment, as there is a chance of breathing poisonous fumes and damaging the airways. Remember, your health is much more important than a well-painted fence.

And finally, a little secret from experts: PF enamel dries for a very long time, and if you don’t have time or desire to wait a few days before each layer, dilute the paint not with white spirit, as indicated on the can, but with ordinary gasoline. It evaporates much faster, and, therefore, the paint dries better.

And in conclusion

As you can see, there are a lot of materials, and all of them have their positive and negative qualities, and before you paint the metal fence, you need to clearly determine what your priority is, price or durability of the coating.