What paint to paint the floor: make a choice

What color to paint the floor will depend on the design of the room. But here the main point will be the material of manufacture and the external environment. It is on these grounds that it is necessary to decide what paint to paint the floor.

Today we will consider this issue and give recommendations on the application materials. Also, you can video and photo in this article where there will be a lot of useful and necessary information on this issue.

The content of the article

The choice of dye for the floor

Any coating is quite capable of being applied with one's own hands, and this will make the price not high. The main thing is to decide what to apply correctly. A lot of materials are offered on the sales market, but this does not mean at all that anyone can apply.

Before choosing, you need to look at which one and where it is better suited. Below is an instruction on the characteristics of different types of dyes.

Impermeable paints

Normally, wood floors or with coatings that do not have a color are impervious to paint. Different pigments enter the structure of those, which show the natural texture of the tree during the application period.

This category of paints and varnishes is indicated by paints in the base of special organic solvents. Such thoroughly protect the plane of the wood from moisture, decomposition and various pests.

You can meet the following types of impermeable paints in the market:

- Acrylic

- Polyurethane

- Alkyd

- Perchlorovinyl

- Oil.

We will analyze the pros and cons (if they exist) of any type of material.

Vinyl chloride paints

They are used to paint wood planes, both internally and externally. They have great weather resistance characteristics, a saturated color palette with bright colors and are quite inexpensive. However, along with these advantages, there is also a minus, the factor of which perchlorovinyl stains “resign”.

It is possible to attribute to them:

- Virulence, since an unstable organic solvent enters the color structure, evaporating from the plane of the tree, has a negative effect on the state of human health, also such volatile elements are quite fire hazardous;

- Coating crackingI am;

- Significant level of fading.

Oil dyes

Almost 10 years ago, oil paints were used by frantic triumph among buyers. However, not because they were excellent, but because there was no other choice. Despite today, some people prefer to purchase directly oil paint coatings in order to improve the floor in their own buildings and apartments.

- They have a bright deep tone, smooth homogeneous texture, significant stability to the change of temperature systems and the most important - low cost.

- The disadvantage can be considered a long drying time, it will take about a day when this paint dries, which is extremely and extremely sad. In our period of time, no one prefers a long wait. After a few years, you will no longer enjoy the smooth and shiny floor. And you will begin to see a rough and periodically even cracked plane.

- If you think about how to paint plywood on the floor, then oil dye is completely suitable.Indeed, plywood has a thickness limit and oil paint protects it perfectly.

Polyurethane paints

They are characterized by great signs of wear resistance and stability to external influences, excellent safety qualities and durability, however, along with this, there are also disadvantages (as without their absence).

- Polyurethane dyes have significant toxicity due to organic solvents entering their structure.

- The price of such materials is quite high.

Alkyd paints

They are used to protect wood planes from the inside of rooms and externally. They are characterized by considerable resistance to atmospheric precipitation and various fluctuations in temperature and colorful colors. However, the disadvantages of such paints will force you to think about it 100 times rather than risk taking them.

- During the staining period, a very powerful special aroma is spread, it remains after drying. Of course, do not assume that it will be necessary for you to breathe paint throughout your life, of course not. Without exception, during this period it is more correct for everyone to be in a different place, so breathing like air is risky for well-being, and after a few days, maybe several weeks, the “smell” disappears.

- Organic solvents entering the structure are quite flammable, for this reason the paint very quickly and easily ignites. Acrylic dispersion paints have been in great demand in recent years and not in vain!

They have a number of positive aspects:

- high weather resistance

- moisture resistance

- cold resistance

- burn resistance

- large color palette (more than two thousand of the most various colors)

- reliability (up to ten years of service in the absence of the tiniest bickering).

Of course, the only gloomy circumstance upsets the good look - the cost of acrylic paints is quite high, of course, and the selection of manufacturers is not so huge. Therefore, in the Russian Federation such products are not produced at all now. In this case, everything that arrives to us “from behind the hill” is not always of good quality.

For this reason, be careful when selecting acrylic paints, drawing your attention to the marking and state of the manufacturer. For a wooden floor from Spain or Germany, the paint is not worse than the widely advertised Finnish.

Their structure is almost identical, of course, and the properties are similar. Why pay more if it is possible to purchase the exact same, but with the most attractive cost.

Colorless coatings for wood planes

Transparent varnishes and impregnating agents belong to this type of paints and varnishes. Let's analyze any type separately.

Colorless dyes include impregnation:

- Acrylics differ in significant absorbency in wood. This makes it possible to save the floor plane to the maximum. Such impregnations have every chance to have different colors, with the help of which it is possible to form an unusual and magnificent design. An ordinary bunch or roller, the composition is applied. Spraying is also provided, since not everyone is able to spend two hours of their own desired period in spreading the impregnation on the floor.

- Oil impregnations are used to protect, maintain and tint logs. They are perfectly impregnated, which is why the plane of the wood becomes strong, sparkling, even the most moisture resistant. For impregnation, the oil is made from naturally modified resins, usually linseed or wood oils.

- The scope of its use is quite ambitious: living rooms, guest rooms, kitchens, bathrooms (see In the bathroom, painting walls: how to do it right), village, pool, in the aggregate, almost everywhere, including the place where there is no heating.Just update the oil impregnation if you need to add specialized products to mop the water.

- Own the weight of the positive aspects of varnishes. They leave the natural beauty of wood, protect the floor plane from the harmful effects of external conditions, but they can’t absolutely enjoy the lacquered floor, since the refined lacquer film is not able to protect the floor from spalls, impacts, or any loads.

- Including when the varnish is completely dried up, without exception, it just as well remains sufficiently flexible, mobile and moving with each defect simultaneously with wood fibers. In general, there is no sacrifice, for the sake of charms, to move on the varnished floor only in slippers with a delicate sole.

Selection aspects for paint flooring

There are several criteria according to which you need to choose the color for the floor.

Here they are:

- Type of flooring (woody (seeHow and how to paint a wooden floor) or concrete);

- Floor loads;

- Wood texture (origin of the log);

- Where will the painting begin?a: from the inside of a ventilated or non-ventilated building, on the street, this implies continuous accumulation of precipitation on the plane, in circumstances of high atmospheric humidity, and so on;

- Certain colors invoke specific circumstances.and this: epoxy paints, to the sample, must be done only in well-ventilated rooms, in which case latex-acrylic is excellent for non-ventilated rooms;

Attention: For paints and varnishes of concrete placement, it is necessary to take into account in which place repair and construction activities will be laid: if the premises are apartment-type, in this case it is necessary to select a paint that has less toxicity.

In a similar way, understanding several options, you can provide a detailed presentation of the required color to the merchant - an expert of the shopping center. The dealer - expert simply after this should advise you to choose one or another paint for painting the flooring.

Wood flooring

Wood flooring should be varnished. Low wear resistance of this type of used material is considered.

Thus, if you leave the wood and not cover it with anything, it is unlikely that it will last for more than two, 3 years. After a little time, moldiness, decay can occur on it, it will begin to swell, dry and change shape, for this reason it is not unimportant to choose a more optimal color for the log.

Without exception, all paint coatings for logs can be divided into 2 types: colorless and impermeable. Colorless coatings are specialized varnishes for parquet, where such a look makes it possible to highlight the natural beauty of wood. However, this topic is for another note.

However, it is our concern to cover the flooring with one or another paint, and if we touch upon multi-colored ones, in this case oil paint from natural goods was definitely used during the period of our grandparents. In the majority of situations, paint was made from ocher, and the most common color was blood - chestnut (red).

The problem is that directly this kind of tone, according to the judgment of the manufacturers of paint coatings of these pores, was able to perfectly hide the dirt in the floor.

- Acrylic dispersion paints enable wood flooring to “breathe”.

- Until now, there are oil paints on store shelves, they are sold at an affordable price, the painting procedure is quite simple. A strong coating, which is formed due to the application of coloring on wood flooring. Secured will last for you for about five years.

- Dispersion acrylic paint has several positive aspects over others: a large coefficient of vapor permeability (ability to “breathe”), solvents are not included in the composition (thus, the least type of fire hazard, no toxicity), the greatest adhesion to wood, lightness and practicality of the flooring, optimal protection against ultraviolet radiation, with proper care, the operation period reaches up to twenty years.

Attention: In the event that after an indefinite period of time you wish to repaint the flooring with another type of paint and varnish, in this case try a water - acrylic solution. This mixture will give the minimum “resistance” from among absolutely any paints and varnishes!

- Opaque enamels have every chance to be applied because of their own cheapness and simplicity, but in addition they perfectly overcome moisture, owning a powerful waterproof quality.

- Enamel paint generally dries faster on wood flooring.

- Enamel holds well on the plane of the log, without breaking through into its texture. As a result, the period of operation of the wood coating is significantly increased. Another advantage of this type of paint material is considered to be a rapid drying period.

Concrete flooring

Let’s try to find out how to choose a color for the flooring from concrete slabs (seeConcrete floor painting: do it yourself), because this kind of plane needs to be painted over according to most circumstances. In this case, do not forget that dust will regularly form in an unpainted concrete coating.

Do not forget, besides this one, that concrete slabs unsecured with paints and varnishes have every chance of being a factor in injuries (it is possible to stumble).

Attention: Here you will find the answer how to paint the bulk floor. In the matter of concrete, the main factor will be the peeling of the dye. Therefore, before painting, it will be necessary to carry out a primer of the plane, only then will the coating stay.

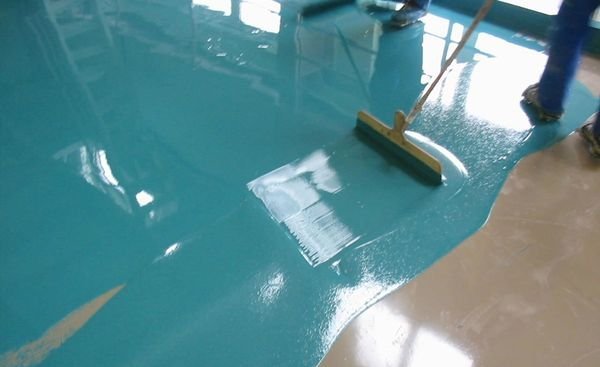

- In general, epoxy paint is more often used, which is what is called “epoxy”. Causing an already delicate coating in a concrete coating provides for you to increase the wear resistance by many times (it is more correct to apply paint in 2 layers as a whole: first, apply the thinnest layer, which must be allowed to dry in order of about a day, then cover with a second layer of huge thickness) .

- Epoxy paint has a waterproof result, increases the degree of overload. The most resistant to the influence of chemical elements, in addition, has excellent adhesion to a concrete surface.

- Epoxy paints are suitable in an open area for concrete floors.

- Suppose you need to cover the flooring in an open place, in which case you can directly pick up this kind of paint material.

- It should be noted separately innovative concrete coatings, which are presented from European manufacturers. They are able to withstand a large load. Such colors are more suitable for industrial areas, but here it must be emphasized that Europeans paint floors in stadiums, where one of the drawbacks is the high price of the product.

If you decide how to paint the floor in the steam room, then there is only one question, it’s better not to, because here, in addition to a damp environment, high temperature also affects and therefore any dye will not be safe. What paint to paint the floor in other materials of manufacture, you can easily find in the article. The main thing is not the price of the dye, the main thing is that it is safe and durable.