Heat-insulating paint: material features

Heat-insulating paint appeared on the market not so long ago, but already has its admirers. Moreover, it can sometimes be difficult to find a replacement. Manufacturers of heat-insulating paints are constantly improving their products and make this material attractive. On the video in this article you will find the necessary materials on the use of this composition.

The content of the article

Composition and properties of heat-insulating paints

The composition of heat-insulating paints, in addition to water, acrylic dispersion and fillers, includes additives based on perlite, fiberglass, foam glass, and ceramic microspheres.

Heat-saving paints have a number of properties that spread its application:

- Protective function It protects various building structures from: heat loss, corrosion, moisture, mold or mildew.

- Protection of building structures from mechanical damage, which increases the service life of painted surfaces.

- Heat saving saves money on energy savings.

- Environmental friendliness. Warm paints during operation do not emit harmful substances and are absolutely harmless to humans.

Where to apply

Thermal insulating paints can be used for:

- Insulation of building facades.

- Insulation of pipes from freezing.

- Warming of communication systems, gas pipelines, steam pipelines, air conditioning systems.

- Internal and external thermal insulation of housing.

- Thermal insulation of vehicles.

- Protection of heat supply systems from heat loss.

- Basement insulation.

- Use in agricultural production.

- Warming of various capacities.

- Thermal insulation of industrial equipment.

Attention: It is possible to apply liquid heaters both inside buildings, and outside. Unlike traditional materials intended for the insulation of buildings and manufactured in the form of plates, rolls or granularity. Liquid thermal insulation materials are available in special containers.

As you can see from the list, warm paints can be used in almost all areas of the national economy, while warm paints can successfully compete with traditional methods of insulation.

Benefits

Advantages of using warm paints:

- The ability to withstand high temperatures.

- Resistance to weathering.

- UV resistant.

- The paint has a low heat transfer coefficient.

- The durability of the coating.

- High adhesion to all known materials.

- Painting does not require the use of special equipment, except for the spray gun.

- High resistance to mechanical stress.

- High degree of fire hazard.

- The possibility of thermal insulation of inaccessible places.

The main factors affecting the choice of paint

Thermal protective paints for walls are selected according to the parameters. The main role is played by the environment and the plane of application.

- Possible functional loads on the insulating layer.

- Possible consumption of heat paint per 1 square meter, depending on operating conditions.

- It is better to choose paint in the presence of various manufacturers.

- Depending on the conditions of use: external or internal.

- For the facade, paint with maximum water-repellent properties and maximum vapor permeability is better.

- To cover the inner surfaces of housing, you should choose a "clean" paint, without harmful components.

- For painting pipelines, you should choose a paint with maximum heat resistance.

Varieties of heat-insulating paints

Liquid thermal insulation materials include 2 categories of materials, such as:

- Thermal paints (including ceramic).

- Foam fillers (penoizol, polyurethane foam, liquid foam).

These are the most common categories of materials that have a reasonable price, and therefore, are very often used for thermal insulation measures. These categories of liquid heaters have their own application rules and application features. The technology of using such materials differs from traditional ones and more reminds of painting work.

Thermal paints

Thermal paint insulation does not have any features, and the application technology is identical to the conventional paint technology.

- After applying the first layer, you should wait a certain time for the layer to dry, then the next layer is applied, and so on, 5 or 6. The more layers, the greater the likelihood that the warm paint will perform its functions. This is due to the fact that liquid thermal paints have a special structure.

- After application and drying, a dense thermal film is formed on the surface of the paint, which has a much lower thermal conductivity than standard thermal insulation materials.

- At the same time, the film is very thin and one or two layers is not enough for full efficiency. Moreover, the optimal number of such layers may be 5 or 6, and in some cases there may be more, up to 10.

Caution: Particular attention should be paid to materials such as ceramic paint thermal insulation, which form a ceramic peel after drying. This crust helps to increase the durability of the coating and its reliability, as well as mechanical strength.

Application Features

Such thermal insulation is characterized by the fact that it can be applied to surfaces having various geometric shapes, and this is very easy and affordable.

- To do this, you can use a paint brush, although it is more convenient and effective if you use a spray gun (see We select a spray gun for painting) It is important that during application a uniform layer is obtained and there are no gaps, otherwise there is no point in applying such an expensive paint.

- If the work is carried out indoors, it is advisable to use a respirator so that ceramics do not get into the lungs. This is true for any paintwork.

- The instruction says that the paint dries quickly enough, but if you take into account that there can be 5 or 10 layers, during this time you can seriously breathe thermal paint and extra safety measures will not hinder.

Foam Insulators

For thermal insulation work, both inside and outside buildings, the following foam materials are used:

- Penoizol.

- Polyurethane foam.

- Liquid foam.

These materials are fundamentally different from thermal paints, both in the method of application and in the technical characteristics, but at the first acquaintances they are easily confused with polyurethane foam.

Work with penoizol (liquid heaters like Astratek), its application technique, drying time, and also consistency, is completely similar to polyurethane foam. This is due to the fact that such materials belong to the same parent group and have a certain kind of polyurethane foam.

- The basis of such a material is a polymer that reacts with air and forms a dense material when dried. This polymer is mixed with foam-generating material, as a result of which, when applied, a lot of foam is formed that can fill a certain space.The foam-generating substance has good adhesion to any building material, and the application technology is quite simple. The dried foam has an acceptable strength, as well as good thermal insulation performance.

- Convenience of using penoizol is that, having excellent adhesion, it does not drain from a vertical surface and is on it until it completely hardens. After 30-50 minutes, the foam begins to harden, and after 3-4 hours, the hardening process ends. This process is completely dependent on the ambient temperature. After 3-4 hours, the insulation begins to increase its strength without changing its size.

Penoizol is the most affordable and easy to use. Many companies involved in the insulation of industrial buildings work with penoizol, so it will not be difficult to purchase it.

Attention: Being in great demand, there is a fairly large amount of penoizol on the market, in addition, there is equipment with which penoizol is applied to building surfaces. In this regard, this material has a lower cost compared to polyurethane foam, and also has a simple preparation technology and excellent technical characteristics.

At the same time, penoizol is harmless to humans and this is an indicator that, without any restrictions, it can be used for wall decoration inside residential premises.

Polyurethane foam has similar technical characteristics, but much more expensive than penoizol. If you believe the experts, then polyurethane foam copes better with its tasks, and therefore, it costs much more.

Liquid foam Is polystyrene mixed with a foam-generating substance. Such foam is distinguished from widespread foam plates by its structure and density, but after hardening, these differences disappear, although in the hardened form, the liquid foam is more similar to foam, since air bubbles can be observed in the hardened material.

Recommended Manufacturer

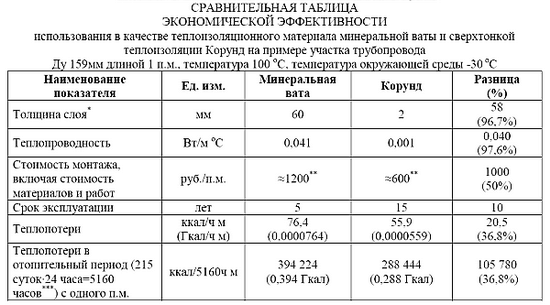

Paint thermal insulation corundum is currently popular. You can see her indicators in the photo below. This coating is applied without problems with your own hands and is therefore quite attractive, because the price of such insulation will be lower than traditional. This is armor that not only protects the surface, but also insulates it.

Attention: The paint is applied to the surface with a layer 2-4 mm thick, which is quite enough to replace several tens of millimeters of traditional insulation.

Paint allows you to apply the material to the surface in a uniform layer. In addition, the technology of applying paint allows you to insulate the most uncomfortable places, which it is not possible to insulate with traditional methods.

In density, they resemble a thick paste of white or gray. This paint is easier to apply with a spray gun, which will provide a more even coat.

Attention: The thicker the paint layer, the more effective the thermal insulation. The service life of the insulating layer is from 12 to 40 years, and operating conditions are determined by the temperature regime from -70ºС to + 260ºС.

Conclusion

In conclusion, it is worth noting that modern high-tech building materials, designed to warm various elements of structures with difficulty, fit into modern life because of the high cost. Therefore, to warm the house with such materials, you will have to shell out a lot of money, especially since it is problematic to use such materials yourself, therefore, the cost should include the cost of work.

If, for example, penoizol is used, then the price of the material is not so high, but the work on its use can be shocking.

Not every average citizen can afford to purchase such insulation materials, despite their effectiveness and ease of use. Most likely, richer citizens will be able to feel the results of the achievements of science and technology, and the middle class will be content with traditional, no less effective insulation technologies, but cheaper.

The use of warm colors can be justified in places where traditional methods are not acceptable, as they can take a lot of usable area. This applies to all kinds of communications, such as water supply, gas supply, sewage, etc. The use of such materials can be effective, although it absolutely does not take up much space. This property of them will be appropriate if it is necessary to insulate a complex structure without violating the architectural integrity of the ensemble. Then there is practically no alternative to the use of heat-insulating paints, just as there is no alternative to energy-saving technologies.

Liquid heaters can be attributed to the latest materials, so they are not widely used, due to a certain mistrust of new materials and new technologies. But it is quite possible that in 10 years, new materials will successfully supersede old ones and people will prefer only new technologies, albeit expensive ones.