How is powder painting performed?

Surely, many have heard about powder paints, but few people imagine how this looks and happens. In this article, we will talk about what powder coating of metal products is, and why it is considered the highest quality and most durable among even the most expensive, liquid paints.

The content of the article

What it is

Well, let's start with the thesis - powder coating, this is not only a decorative coating, but also the protection of a metal product from corrosion and all kinds of environmental influences. An interesting fact is that powder paint - in fact, being a resistant polymer, is able to withstand a fairly strong mechanical stress, that is, when a metal is hit and bent, the paint also takes an appropriate shape and does not crack.

Thanks to these qualities, powder polymer is increasingly used for painting cars and even those parts that are most often exposed to aggressive effects, for example, those located on the bottom. Of course, the cost of painting powder paint is high, but if you take into account all the positive qualities of this material, then the price becomes not so sky-high.

And in order not to be unfounded, we list some of the most basic advantages of this material:

- Full water resistancemoisture, and as a result, corrosion.

- High adhesion to metal thanks to temperature application.

- Resistance to mechanical stress and deformation.

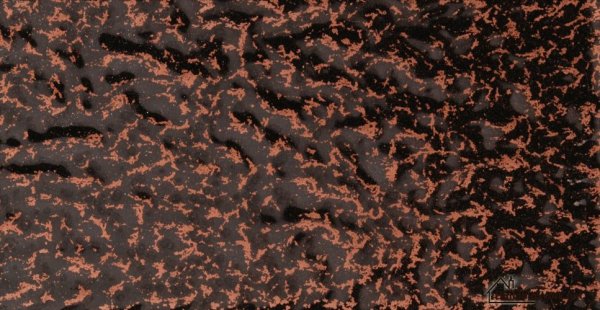

- Attractive appearanceinherent only to this type of paint.

- Durability. Manufacturers of powder paint give a guarantee on their products, from 25 years under conditions of use in an aggressive environment.

- Metal painting with powder paint in compliance with all technological nuances, very economical, since the material does not fly into the atmosphere, but accumulates on special filters, after which it can be reused.

- Powder paint can also be used on wood surfaces., but the polymerization process will be completely different.

Unfortunately, there are a number of drawbacks, but all of them are associated not with the qualitative side of the issue, but rather with the technical, that is, related to the application of paint on the product:

- Powder paint is applied in several layers, which significantly increases the final cost of the product.

- Due to the difficulty in working, painting with powder paint at home, and with your own hands is almost impossible, well, or difficult.

- If necessary, remove the old coating of powder paint, it will be very difficult to do.

- Possible defects in powder coating are very difficult to fix, although they appear only if the application technology is violated.

Important! To create a high-quality coating, it is not enough just to apply paint to the product; preliminary preparation, namely cleaning and removal of all defects, is much more important.

As you can see, it is quite possible to put up with the shortcomings of the material, but if you still have a desire to try to paint something yourself, then detailed instructions are given below for working with this material.

Self painting

A full-fledged powder coating workshop is a technologically complex enterprise that requires considerable investments. And of course, that for infrequent work it is unprofitable to build it.Therefore, you can get by with small losses and set up your own small production, although you can’t do without buying special equipment.

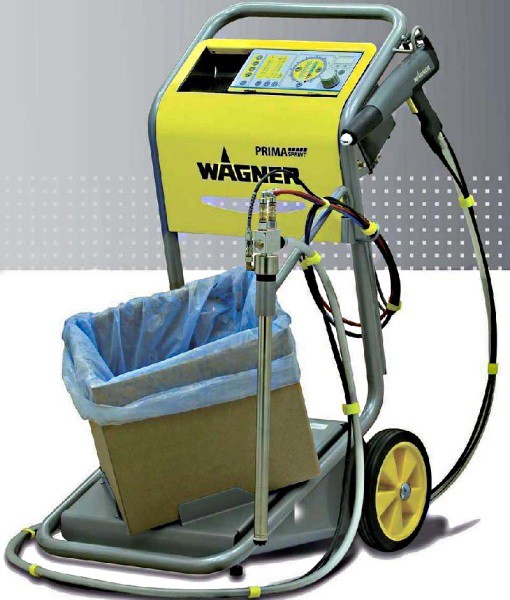

The first and most important acquisition is a spray gun, since a tool for liquid paints is not suitable here. The main difference between the spray gun for the powder is the presence of an electric drive, which saturates the paint with positive charges, while the product being painted has a negative charge, that is, "mass".

Due to the difference in polarization, the powder does not just lie on the metal, but penetrates the structure of the metal itself, becoming one with it.

The second distinctive development of the spray gun is the increased working pressure, since dry powder is much harder to lift than liquid paint.

Important! As a rule, spray guns for powder paints come complete with compressors, but you can pick them up separately, the main thing is to correctly adjust the working pressure.

Polymerization chamber

Another important element that greatly affects the cost of powder coating of metal. The fact is that polymer paint takes its final texture, only under the influence of high temperatures. The powder melts, and penetrating the metal structure, becomes one with it.

In the photo above, a ready-made large-capacity polymerization production chamber is shown. In such chambers, cars or large-area products are heated. In principle, it is not difficult to build such a camera on your own (see Do-it-yourself powder paint oven), unless of course there is some knowledge in electrics, well, or there is a friend who can help.

To create a do-it-yourself polymerization chamber, we will need the following elements:

- Metal profile pipe for the construction of the frame of the chamber.

- Basalt wool sheets for insulation and sealing.

- Galvanized iron sheets for interior and exterior cladding.

- Closed-loop fan to create constant forced air circulation inside the chamber.

- Heating elements are calculated so that the temperature in the chamber rises to 200 degrees.

- Two thermocouples for measuring the temperature at the bottom and top of the camera.

- Automation for temperature control and adjustment.

Important! Self-painting with powder polymers is not performed in the polymerization chamber. There, the product is placed already after applying the paint for final drying and strengthening adhesion.

Painting

If powder painting is carried out in a garage, it is very important that the air contains as little dust and other volatile impurities as possible. As a rule, dust particles have a positive electric charge, which means that when mass is attached to the product, they will immediately begin to stick to the metal and subsequently it will be very difficult to remove them.

As a rule, painting takes place in three stages, apart from the fact that sandblasting and removal of all contaminants from the surface of the product is required:

- Padding.

- Painting.

- Varnishing.

Of course, the last stage can be skipped, since it carries only a decorative function, although it enhances the properties of the paint.

Advice! In order to paint the product in several different colors, you will need a heat-resistant adhesive tape for powder painting, which can easily withstand high temperatures in the polymerization furnace.

The whole complexity of powder coating lies in several coating layers, that is, after applying each layer, the product must be placed in a furnace and heated to a certain temperature, and each type of coating has its own mode and heating height, which we will present in the table for clarity.

| Layer | Temperature. 0with |

| 1.grunt | 150-160 |

| 2.paint | 180-190 |

| 3. varnish | 200 |

The residence time of the product in the oven depends on the manufacturer and the thickness of the layer, but on average it is about 15-20 minutes, and after the oven is turned off, it must cool itself closed when closed to 100 degrees, after which the product can be pulled out, cooled to room temperature and cover with the next layer.

A more familiar with the process of polymerization in the furnace, you can watch the video in this article.

To summarize

If we compare powder paint with competitors, then it clearly wins them both in quality and in service life. Of course, if it is necessary to paint just one product, to organize a paint section, to put it mildly, is inappropriate. In this case, it will be easier and cheaper to pay specialists who will do everything in the best possible way and in compliance with all technological standards.

As for the private business, with the use of powder dyes, today, this direction is becoming increasingly popular among consumers. And even despite the costs, which may turn out to be considerable, in the near future, everything will return and begin to generate income.