SNiP: brickwork of walls and partitions - a guide for independent work

Considering the fact that the price for the services of hired specialists is often equal to the cost of buying building materials, those who want to build a house, garage or shed on their site are tempted to do their own laying work. But how to do it if there is no theoretical knowledge or experience? The search for the necessary information is usually carried out on the network, for queries such as: “SNiP brickwork of walls and partitions”.

Note that there is no single document regulating masonry work with this name. There are norms according to which the design of stone structures is carried out, which will be incomprehensible to an ignorant person. And there are technological maps (for each type of wall), which are a guide for masons. For the convenience of the reader, we generalize and compactify the information contained in them, and accompany it for clarity of the video in this article.

The content of the article

Organization of the process

Issues of organizing and ensuring the safety of work, SNiP laying brick walls pay a lot of attention, since labor productivity, construction time, and the final result depend on them.

Convenience in work is important

First of all, a bricklayer should be able to conveniently move within his plot, and work without unnecessary movements. Professional teams are usually divided into units, each of which consists of 2-3 masons with different qualifications. Which one - it already depends on the thickness of the masonry and its architectural complexity.

The plot is divided into three zones, which is clearly visible in the photo below:

- Working - This is a strip along a wall segment, up to 70 cm wide, where masons work;

- Material Storage Area - a longitudinal strip up to one and a half meters wide, on which ordinary brick and mortar are placed. To perform masonry with simultaneous cladding, this zone should be twice as wide, since more space is also required for the front brick.

- Auxiliary plot - an area for passage, takes a little more than 0.5m.

When openings are provided in the wall, a container with a solution is located opposite them, and it is more convenient to put a pallet with a brick on the line of the wall. If lightweight masonry of walls is carried out, then the basic materials alternate with reinforcement and loose aggregate, or other heat-insulating material.

Solution

All materials must be prepared in advance, and only the solution is supplied immediately before the start of masonry. In the construction of a small private house, it is much more convenient to knead it on the spot, using factory-made masonry mixtures, which many manufacturers call “sand concrete”.

These are universal dry mixes M150, which are suitable not only for laying bricks, but also for plastering wallspouring floors. Compositions of a higher grade are used for pouring the foundation, armopoyas, monolithic lintels. Such packaging, as in the photo below, costs about 160 rubles. Colored mortars are usually used for laying decorative bricks.

- Factory dry masonry mix

- Tinted mortar for masonry

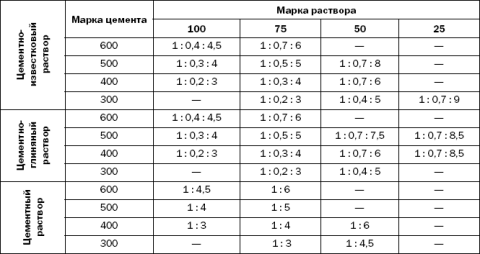

- If you think that buying ready-made mixtures is expensive, nothing prevents you from installing a concrete mixer and making the solution yourself. When brick walls are being erected, SNiP provides for the use of simple and complex masonry mortars.

- In the composition of simple there is only one astringent, in complex solutions there are at least two of them. In the first case, this is a cement or lime mortar, the second option: lime-cement or clay-cement. Lime and cement play the role of a modifying additive, and make it possible to obtain a solution with higher ductility.

- The most popular cement mortar with lime additive, as it is suitable for all types of bricks, except for raw clay stone (adobe). He just needs a clay-cement mortar, which is also suitable for the construction of any outbuildings.

Instructions for the proportions of binders and fillers in solutions are presented in the table above. The first in the line is cement, then the second astringent, and then the sand. Water is added until the required consistency is reached, but usually its amount does not exceed 30% of the total mass. Sand can be used heavy (quartz) and light (pumice, slag).

Tools and fixtures

The set of equipment used in the work depends on the volume of work and the complexity of the task. On the construction of a one-story house, some fixtures may not be needed, but the main set of tools should be the same as you see it in the table below.

| Tool appearance | Appointment |

| There are many types of trowel, but such a triangular version is ideal for the work of a mason. This form allows you to select a solution in the corners, for which the tool nose is smoothly rounded. Its handle has a flat, sometimes even a metal heel, so that it is convenient to tap a brick. The cloth of the trowel should be made of stainless steel, and its edges are pointed, which allows you to hang a brick. On average, the length of the scapula is 16 cm and the width is 11 cm. | |

| This tool has a striker on the one hand, and on the other a flat extension, which is called a pickaxe. It is pointed, which allows you to divide the brick into halves, or quarters and three-fours. It is also convenient to wield with it, if you need to repel old plaster. | |

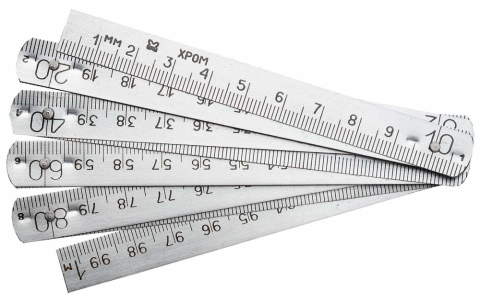

| Along with roulette, a meter may be needed in the work of a bricklayer. In some situations, it turns out to be more convenient to use, since a second person is not required to measure a distance exceeding the length of an outstretched arm. | |

| Using the hydraulic level, the exact marks of the floor and ceiling are determined. | |

| This device allows you to control the position of structures and rows of masonry horizontally. If plastering work is ahead, it is better to immediately purchase a rule with a built-in level. | |

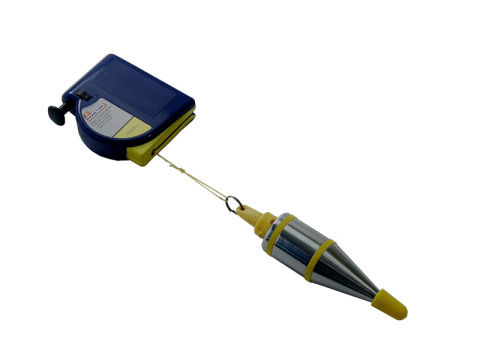

| A tool to control deviations of the wall plane from the vertical. | |

| Angle control of adjacent structures. | |

| Container with mounting loops for supplying mortar to the floor with a crane. | |

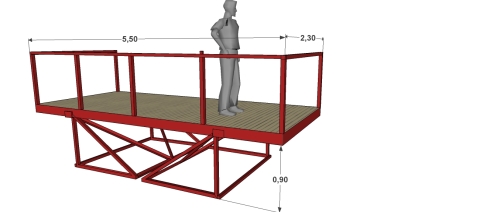

| The device for working at height. | |

| With the help of a stretched cord, horizontal rows are controlled. | |

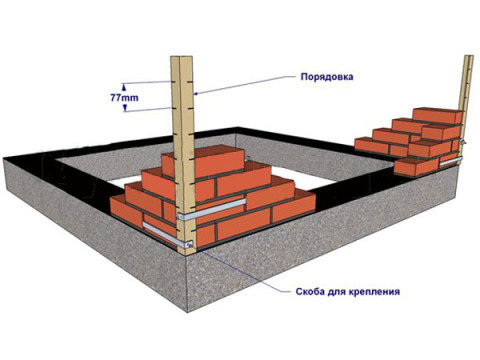

| These are wooden or aluminum rails with the marks applied every 77 mm. This distance corresponds to the height of a single brick, plus seams. Ordering ensures the uniformity of their thickness. |

Masonry work

Work operations performed during the masonry process are unequal in complexity. Accordingly, they are performed by masons of various qualifications. Depending on the task, the composition of the links is determined.

So:

- Masons with a higher discharge are engaged in the installation of orders and moorings, lay out beacons, perform facial masonry (outer milestone).

- Low-skilled workers are laying out bricks, spreading a mortar bed, laying back-up rows, filling voids in the masonry.

- The specific number of masons in the links, and the division of duties according to their rank, depends on the thickness of the wall and its design features.

- For example: for masonry walls in 2 bricks, five masons are required: one V or VI category, one IV category, and the rest not lower than III category.

So, independent work is out of the question here. Another thing is the partition - in the presence of a quick assistant, the owner may well erect it himself. However, he still must have an idea of the work performed by wage workers.

Features of lightweight walls

The main advantage of houses built of brick is their durability. Therefore, when a person wants to build what is called, for centuries, he prefers this particular material. Moreover, in a low-rise building, even walls with a thickness of only one full-bodied brick, can withstand loads from reinforced concrete slabs.

- The reliability of structures in this case depends only on the correctness of their installation and the quality of the masonry.

- The minuses of brick walls include only their solid weight, and low thermal performance. However, both of these disadvantages are eliminated through the use of lightweight masonry technologies.

- This is the use of hollow (slit) bricks, and the device in the walls of wells filled with liners of light concrete, liquid cellular concrete, foam or bulk insulation.

- These technologies can not only reduce the load on the foundation and make the walls warm, but also significantly reduce the cost of construction.

- Brick concrete walls

- Wall in one brick with cladding and mineral wool insulation

- Wells with expanded clay backfill

- Wall cavity filled with penoizol

To reduce the thermal conductivity of brick walls, masonry can be performed on warm solutions prepared not on quartz, but on pearlite or pumice sand. At the same time, masonry technology with widened seams is often used, which allows to reduce the thickness of the walls as a whole.

In the process of such masonry, the thickness of longitudinally vertical joints increases significantly, and due to this, the brick is laid not flat, but on the edge. We only note that this option of lightweight walls is not suitable for independent work. It is carried out only according to the project, in which the necessary thickness of the joints is assigned.

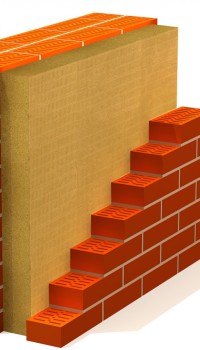

- Masonry with layers of heat-insulating materials is always carried out with a gap corresponding to the thickness of the liner. Its place is between the front verst and the next row.

- In this design, the plate insulation must be provided with a tight fit to the masonry, for which it is first put on glue, and then fixed with dowels with a disk hat.

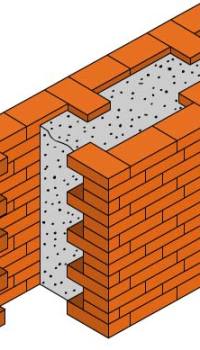

- By the way: today on sale there are not just dowels, but basalt-plastic anchors, which allow simultaneously connecting the insulation to bind the walls to each other.

- One end of the anchor is mounted through the plate into the main masonry, and the second end, after installing the disk washer, is monolithic in the joints of the outer wall.

Note! If the insulation is mineral, a gap of 3-4 mm is provided between it and the lining, and vertical joints are left empty in the bottom row of the wall itself. This ensures the outflow of condensate, and protects the mineral wool from rotting. Polymeric slabs are not afraid of moisture, which means they do not need ventilation.

If the wells are filled with concrete or foam, then usually in every fifth row they arrange the release of stitch rows, which should play the role of anchors.When using bulk materials, the walls are connected by strips of fine-mesh steel mesh, which not only provides a rigid fixation of the walls, but also does not allow the insulation to settle and stray below, leaving voids on top.

The structural nuances of masonry

For the construction of the outer walls of low-rise buildings, almost all types of bricks are offered, which are now offered by manufacturers. In addition to clay bricks: both full-bodied and slit, these are also hyper-pressed and silicate stones.

Limitations of the last two options apply only to the foundation and basement of buildings, as well as rooms operated in high humidity.

So:

- According to SNiP: brickwork of external walls, their thickness cannot be less than 250 mm - that is, the length of one brick. The minimum cross-section of pillars (columns) is 380 * 380 mm.

- As for the partitions (seePartitions and walls - what is the difference), then when laying the brick flat, they will have a thickness of 120 mm. If the length of such a partition does not exceed 3 m, then the masonry may not be reinforced.

- But there is also a technology for the construction of brick walls 65 mm thick, in which the brick is laid on the edge. In this case, reinforcement with steel wire of every third row of masonry is necessarily carried out.

- The laying of the outer verst should be done of the highest quality bricks, leaving those of them that have cracks and chipped faces to a blank. If the walls are not supposed to be plastered, then it is better not to sort the ordinary brick, but immediately buy the facing.

Lighthouses

The thickness of ordinary (not broadened) seams can be 8-15 mm. As a rule, a thickness of more than 10 mm is made when reinforcement is laid in the seam or the ends of the anchors are monolithic.

Laying is carried out on a well-aligned surface of the foundation, and begin from the corners. On them, as well as in the areas where the openings are located, the lighthouse bearers tapering upwards (runaway) up to 6 or 8 rows high.

Note! You can still do without lighthouses when the building is small, and a large team is working on the construction of its walls. Otherwise, the masons have to take breaks, and the strokes make it possible to firmly connect the fresh masonry with the masonry made earlier.

When the beacons are erected, a cord is pulled between them from the outside. Then begin the laying of the outer verst, which is flush with the upper bricks of the shtrabi. With a wall thickness of one brick, then an internal milestone is performed, which, like the outer one, will be a spoon.

After 6 rows, two spoonful versts are tied with a poke row. According to this principle, dressing is carried out according to a multi-row pattern. But there may be other options - for example: when the artistic laying of walls is performed.

Jumpers

Equally important is the device jumpers over the openings of windows and doors. In houses with beam ceilings, which do not have such a significant weight as concrete slabs, they can be laid out of brick. In those cases when concrete ceilings rest on the walls, the bulkheads are either prefabricated concrete, or a monolithic armored belt is poured over the opening (seeReinforced belt on load-bearing walls according to all the rules).

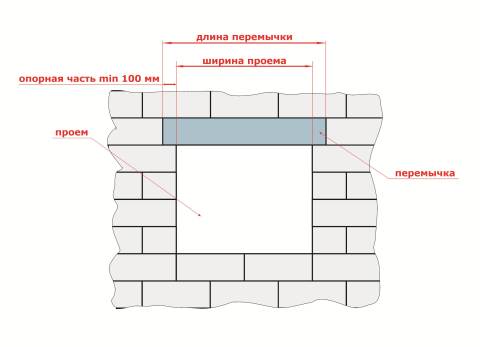

- Since structurally all the jumpers are different, then they rely on the masonry unequally. In both private and large-scale construction, in large esteem precast concrete lintels.

- Plate-type jumpers, that is, having a width greater than height and immediately covering the entire opening along the wall thickness, require support heels of minimal depth - 10-12 cm is enough.

- For bar jumpers, which, having a height greater than the width, are not so stable, 25 cm per end are required. At the same distance monolithic in the masonry and jumpers from a steel channel or corner.

- Brick lintel in a small opening

- With significant loads, only a concrete bridge is needed

However, where the masonry does not carry any loads, except for its weight - for example: in brick cladding, or in the filling of frame-brick houses, it makes no sense to put concrete lintels. It is much more convenient, and cheaper, to use metal for this purpose. Its advantage is its low weight and the ability to cut any length.

Brick lintels are arranged only on openings less than two meters wide. Although, today there is a technology with mounted consoles that reinforce the masonry over the opening, and allow you to make bridges of brick over the openings of any width.

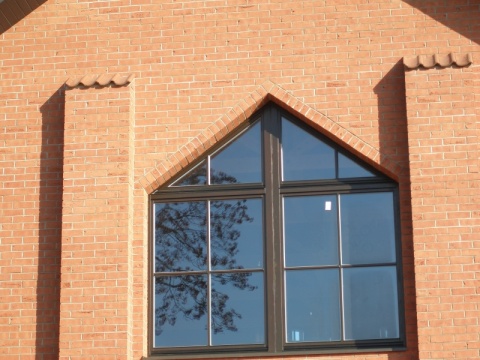

If the lintels have the role of architectural decoration of the facade, then they should be made only of brick. In any case, the openings of a triangular and arched form cannot be blocked in a different way.

To cope with this task no "SNiP brick walls" will not help. An excellent tool will be the technological map (TC) No. 95-04 for laying arches and arches made of bricks. But still, the best assistant is the video, and after watching several professional videos, it is quite possible to master the independent execution of this element of masonry.