Decorating a summer house block house: how to do it

Decorating a summer house with a block house has recently appeared on the market of offered services. And many are quite satisfied with this type of finish.

But many do not know how to do this work on their own, an unfamiliar name is simply scary. Although there is nothing new in this finish, everyone will be able to do this work with their own hands and without resorting to outside help.

This article will be devoted to this topic. You can see the photo and see what it is.

On the video you can see the rules of the work.

The content of the article

Choose a block house

If you are satisfied with the styling of the cladding with this material, then you should familiarize yourself with it better. Find out what it is good and then choose the material for the manufacture of this product.

So:

- Wood material that has a natural moisture repellent. In the production of wood, both hardwood and coniferous species are used.

You will get a beautiful appearance of the structure and it will give the impression that the structure consists entirely of high-quality timber.

Attention: When buying material, make sure that it is of high quality manufacture. Many neglect this.

Inspect and make sure that the geometric shapes are correct. There should be no knots.

See the certificate of quality. There is a clause on wood moisture; it should not be higher than 20 percent.

It will be correct if you check this parameter. You can write anything. Let the seller measure this figure with you.

- Vinyl material, which is much more durable than natural wood. It does not rot and repels moisture.

Several textures are on sale. You can choose the color of the material.

Imitation can be made for valuable species of wood, and the first time you can not distinguish at all. The price of panels is cheaper from wood; - Block house for decoration dachas made of metal, also already on sale. They are made of galvanized sheet metal.

A polymer coating is applied to the outer surface, which also serves as additional protection. This design is much cheaper than the first two options.

Only this option is more suitable for finishing industrial buildings, it does not create the necessary comfort.

Now let's see how we can like this finish and what are the negative sides of this option:

- The positive side should immediately include the fact that you get an environmentally friendly finish, which will differ significantly from others;

- The price of the material is quite different, starting from the cheapest and ending with expensive species of wood. You can choose exactly what the wallet will allow;

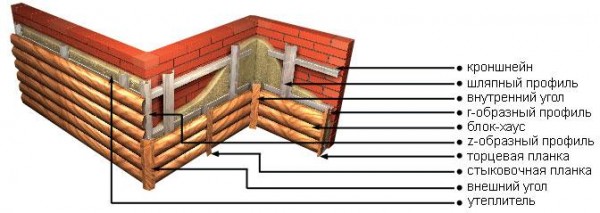

- You can carry out additional facade insulation, and this will increase the cost of work exactly by the price of insulation;

- Decorating a block with a house in a country house is a rather durable construction, which, if properly installed and maintained, will last more than a dozen years;

- The coating will be fully ventilated, which will well affect the base plane;

- The material does not particularly respond to ultraviolet and the original appearance will remain long enough;

- It tolerates temperature extremes and protects the room from external influences.

The picture will not be complete if you do not know the negative features for each type of cladding:

- When installing wooden elements, you will need to take care of the panels. Natural wood in this matter is quite expensive, and it takes a lot of time.Moreover, this material is quite easily ignited;

Attention: Before installation, the material should be treated with special antiseptics that are available on the market.

This will significantly increase the life of the entire structure. Use water repellent when painting

- You can’t install metal material just like that; according to the instructions, insulation must be done at the same time.

We make the decoration of the building

It is quite possible to do this work with your own hands without resorting to outside help. The whole process should be divided into several stages of work.

And it doesn’t depend, it’s the decoration of the cottages block for houses or any other premises.

Caution: Be sure to make forests. You will need to do the fastening of the elements and it will not work on the knee.

Or it will turn out, but not qualitatively. You should be able to move freely and do work.

Otherwise, you will spoil the material and you may get injured yourself.

Installation of the crate

All panels should be securely fastened. They have a certain look.

The appearance and durability of the structure will completely depend on the quality of the frame.

So:

- First you need to prepare the surface for installation. To do this, remove all the protruding parts of the frame of the room.

Nothing should bother us; - Remove the old coating. To do this, use a brush for metal.

If your house is plastered, the entire coating can not be removed. But those places that began to exfoliate should be completely cleaned; - Now the surface should be treated with an antifungal antifungal. Do this without fail, even for the sake of prevention; these are not such high costs that can be neglected;

- First of all, we need to determine the level of fastening of the crate. After all, the walls are not always smooth.

To do this, it is best to pull the fishing line between the diagonals of the wall and it will immediately become clear at what height you need to mount the panels; - Now we determine the installation level of the panels. The houses have a basement, which is often trimmed with other materials.

This is especially true for wood panels. They should not be placed in dense to the ground.

We put a line on the wall. After that, the mark must be moved to other planes.

To do this, it is best to use a hydraulic level, which you should buy or make yourself. With its help, this work can be done most qualitatively.

We transfer and put marks; - Now combine these risks. To do this, we use kapron thread.

With it, we simply beat the level; - Now we need to fix the first starting row of the beam around the perimeter of the room. To do this, cut it to the desired size and nail.

Self-tapping screws are quite suitable for a wooden surface. If the wall for installation is made of concrete or brick, then you need to make holes with a punch, and fasten using dowels.

Do not use kits, purchase plastic separately and screws for it, which take a couple of mm less in relation to the hole. It is such a connection that will be of the highest quality and will support the weight of the structure;

Attention: For the frame, you can use a metal corner or a wooden beam. If you chose the second option, then you need to process the rails with the help of antiseptics, which are available on the market.

Apply a couple of times. This will significantly extend the life of the frame.

- Now we do the same in the upper part of the room. We got two lines of attachment.

After that we do window decoration and doors. It’s not worth it to fasten the planks strictly along the angle line.

Pull back a couple of cm. Finishing material will still be attached here; - After that, we fasten the rails and over the entire plane. The distance is applied about 50 cm.

The most important thing when installing the frame is to withstand the plane of the location of the rails. Do this carefully.

Adjust the height with gaskets; - After installing the frame, we need to apply a layer of waterproofing. It should not be attached to the joint, but overlap of the order of 10 cm.

After this, lap onto the slats and fasten to them using a construction stapler; - Now is the time to place the insulation.

Attention: When attaching the insulation, one peculiarity should be taken into account. It is impossible to deform mats, otherwise they will lose their properties.

They should be marked tightly, but not bent. Provide a couple of see between the surface and the facing. Then you will have quality ventilation.

Panel Installation

This work is carried out in three versions. Everyone will be able to choose the one that suits his fastening.

It depends on the frame material and your desire.

You should remember one truth, the connection is not carried out on weight. It must be done only on a rigid plane.

First option

This work execution option is quite reliable and is carried out using the kleimer:

- With one part of this fastener we fix the panel wood, having previously bent the clamp;

- We fix the second part to the frame bracket using a self-tapping screw;

- After that, we make the clutch with the next panel. Kleimer itself simply wedges the lock and makes the connection more rigid.

In some embodiments, liquid nails may also be used.

In this mounting option, there is no risk of damaging the panel with self-tapping screws and the connection is quite rigid and reliable.

Second option

This option is more complex, but no less reliable.

Here the connection is done directly to the panel:

- First, make a hole in the panel;

- Now we make an abasement so that the cap is completely hidden and deepened in relation to the plane by a couple of mm;

- After that, we screw in a self-tapping screw. The hat is simply putty putty on wood and polished. This completely hides the metal and makes it invisible.

Caution: When making this fastening, you may damage the board. Some advise making a hole for a self-tapping screw to the middle of the panel.

So, this cannot be done. Make a hole through, but it should just be smaller in diameter from the self-tapping screw in half its section.

Third option

Here, fastening is done simply with nails at an angle. Some offer it, but it’s not worth it.

If the material is high-quality and well-dried, then there is a rather high probability of its split. Therefore, it is not worth using.

Advice

There are some difficulties that almost everyone faces. And on this topic, the masters give some tips that will help you do the job most efficiently.

So:

- You may run into the issue of finishing corners. There are plastic pads for this, but sometimes it’s difficult to fix them after installing the panels.

To facilitate this work, it is better to first make both walls and only after that it is necessary to attach a semicircular lining to the joint. Or in another embodiment, you need to make the angle completely hidden.

Then you need to immediately dock the panels, for this a groove is done right away; - As a rule, the last panel does not become completely. Do not make cuts only by taking measurements with a tape measure.

First attach the panel to the mounting location and mark in place. Not always the cut line can be even.

In place, this is done simply completely accurately and then it will be a guarantee that you will not ruin the panel. After installation, the joint is covered with a baseboard; - Difficulties may also arise regarding the decoration of windows and doors. To frame them, it is best to use a special platband.

Then he will hide the backlash and small bumps.

Finishing cottages the house block is finished. There is an instruction and you can proceed to the last stage, this is varnishing or paint.

To do this, it is best to use acrylic waterproof materials that will extend the life of the entire structure.