Materials and technologies for ceiling noise insulation

Noise insulation of the ceiling helps residents of the apartment to protect themselves from the penetration of sounds from the apartment from above. Attaching special materials to the top floor dampens footsteps, furniture movements, and heavy objects falling onto the floor. In an apartment building with thin walls, it is advisable to isolate not only the ceiling, but also the walls and floor. In this case, the inhabitants of the housing will protect themselves from the sounds from the apartments on the right and left, and will not create inconvenience to the neighbors on the floor below.

Protection against extraneous sounds combines two processes - noise isolation and sound absorption. The processes are the same in function (reduction of sound transmission), but different in the mechanism of action. Sound waves from the inside of the room reduce sound absorption, and sound insulation eliminates noise from the outside. To solve these problems, appropriate types of materials and special technologies are used.

The content of the article

Types of noise

The source and nature of household noise determines their types:

- structural - operation of the elevator, ventilation engine, pump;

- drums — the clatter of neighbors from above, the work of a puncher (this noise also applies to the structural type), falling weights, dragging furniture along the floor;

- acoustic - hum, echo in the blown cavities or empty spacious rooms;

- air - screaming, talking, dog barking, music, broadcasting.

Sounds are transmitted from apartment to apartment through building floors, so the soundproofing of the ceiling is the comfort of living. For the arrangement of sound insulation, special materials are produced that differ in purpose, structure, characteristics of density and elasticity.

Soundproofing materials for the ceiling

Ceiling sound insulation is divided into three types:

- Soft. It absorbs 95% of external noise, it is made on the basis of mineral wool or fiberglass.

- Semi-rigid. It is made on the basis of polyfoam (polyurethane foam), absorbs 75% of sounds from the outside.

- Tough. Porous material based on pumice or perlite, dampens 50% of the noise.

Let us dwell separately on common materials for sound insulation.

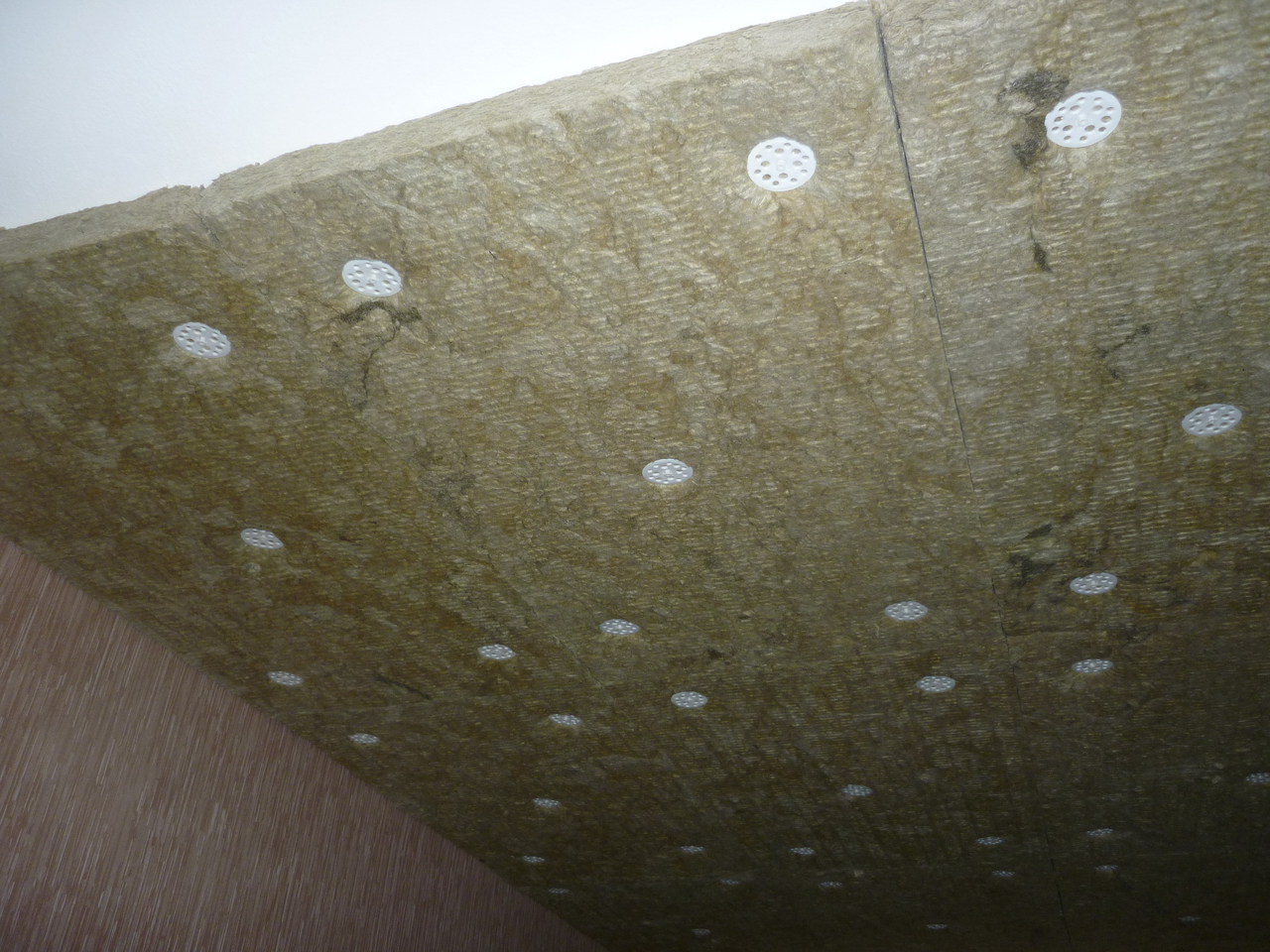

Cotton wool basalt

Scope - ceiling insulation. User reviews characterize the material as easy to install and light in weight. Raw materials for manufacturing are basalt melts. Release form - mats. The material has a fibrous structure.

Material Advantages:

- heat resistance;

- moisture resistance;

- vibration resistance;

- minimum sound conductivity;

- environmental Safety;

- ease of laying;

- lack of harmful discharge.

Material disadvantages:

- high cost;

- seams during installation, which leads to a decrease in insulation characteristics.

In addition to the ceiling, basalt cotton wool is laid on the walls. The material is mounted on a frame or frameless technology. Exterior ceiling decoration is plasterboard stitching and staining.

Cotton wool mineral

The scope of the material is the sound insulation of the ceiling in the apartment. User reviews indicate durability and resistance to deformation. But during installation, a crate is equipped, which is inconvenient for low ceilings. Raw materials for production are inorganic minerals. The material has a fibrous structure.

Material Advantages:

- fire resistance;

- lack of biological and chemical effects on people;

- thermal insulation;

- environmental Safety.

Material disadvantages:

- installation complexity;

- moisture absorption.

The material is used in the arrangement of suspended and suspended ceilings, sheathed with plasterboard.

Acoustic foam

The material is used in suspended and suspended ceiling structures, characterized by simple installation, low weight and low sound conductivity. Acoustic foam is fixed to the ceiling by glue, silicone or double-sided tape.

Material Advantages:

- laying speed;

- durability;

- resistance to mold.

The disadvantage of the material:

- high cost;

- instability to mechanical damage;

- flammability;

- moisture absorption.

Expanded polystyrene

Release form - plates or panels with a thickness of two to ten centimeters. Scope - soundproofing the ceiling. User reviews characterize polystyrene foam insulation as easy to install, but costly. It is mounted in a frameless way, using mounting brackets or glue. In addition to false ceilings where you need a crate. Exterior finish - staining.

Material Advantages:

- moisture resistance;

- environmental Safety;

- low flammability;

- resistance to harmful microorganisms.

The disadvantage of the material:

- high cost;

- instability to mechanical damage.

Bung

Ceiling insulation made of natural materials is rarely used due to the high cost, but in terms of characteristics it competes favorably with artificial materials. Cork ceiling covering reliably protects the apartment from noise from above. A common area of application of cork boards or roll materials is sound insulation of the ceiling in an apartment. Reviews note the ease of installation and the combination of sound insulation with heat saving. Cork is used for suspended and suspended ceilings.

Material Advantages:

- environmental Safety;

- deformation resistance;

- protection against burning;

- easy installation.

The disadvantage of the material:

- favorable environment for the development of microorganisms;

- instability to moisture;

- low strength;

- the need to use special adhesives during installation.

The following are less popular noise insulation materials.

Wood waste boards

Materials serve as sound insulation and finishes. There are no adhesive ingredients in the composition, therefore, boards from wood waste are environmentally friendly. Plates are attached to the ceiling with brackets or glue. Tongue-and-groove structures form a continuous coating without gaps. Used for suspended ceilings and for painting.

Natural fibers

The category of expensive sound insulation includes boards made of linen and coconut fibers. Due to absolute environmental safety, the material is allowed by standards for use in medical and child care facilities. Installation is carried out for suspended and suspended ceilings, external decoration - painting.

Membrane Acoustics

Flexible multilayer materials are used as substrates to protect against impact noise. Release form - roll insulation. Characteristics - durability, small thickness. Used for suspended, false, suspended ceilings.

Liquid Insulators

Sealants for layering, sealing of construction cracks and holes. Costly material, rarely used. It is used for sound insulation of false and false ceilings.

The choice of material depends on financial capabilities, ceiling height, type of noise. The result of arranging sound insulation depends on how well the material is selected. An equally important factor is the right choice of technology and observance of technological subtleties.

Soundproofing Technology

Installation of noise insulation on the ceiling is carried out in a frame or frameless way.

Wireframe method. On the surface of the ceiling, a lathing lath or a frame of a metal profile is mounted. Insulation material is placed inside the frame - plates, panels, mats. Drywall is sewn on top of the material, the surface is painted.

Work execution order:

- The ceiling is cleaned of dust, cracks are sealed with sealant.

- A crate is installed, fragments of rubber against shock noises are laid at the contact areas.

- Soundproofing material is laid.

- Drywall is sewn, joints are sealed, a primer and staining are performed.

Frameless way. Plates or roll materials are mounted on the ceiling with glue, staples or mounting hardware.

Work execution order:

- The ceiling is cleaned of the old coating and leveled.

- Primer is produced.

- The material is glued or fastened with mounting elements.

- Exterior finish.

To strengthen the ceiling structure, use the combined method. For external decoration, use external panels or paint polystyrene foam and boards from wood waste.

Noise isolation in rooms with low ceilings

The frame method is unsuitable in a room with a low ceiling, as it reduces the height of the room. The solution to the problem of low ceilings is thin insulation. For this, special materials are produced:

- membrane acoustics;

- lining soundproofing;

- vinyl noise blocks;

- penoplex;

- cork sheets;

- noise insulation mastics.

A distinctive feature of this group of materials is a thin-layer structure. For installation, the frameless method or the packing of a thin crate is used. Mastic improves the characteristics of drywall for painting. Roll materials are mounted on the ceiling and reduce the level of the ceiling by only 1-3 cm. At the same time, sound-proofing qualities are manifested no less than with “thick” materials.

The videos in this article will help you understand the practical application of technology.

Noise insulation of the ceiling is possible in different versions. This allows you to choose the best material and installation method depending on the size of the housing, the budget and your needs. Insulating the ceiling using simple frameless technology is easy to do with your own hands, a novice will also cope with this task. Frame structures are more difficult work, in the absence of experience it is advisable to entrust it to specialists.