Finishing stairs with laminate and parquet: do it right

In the decoration of stairs, you can use almost all types of coatings used for flooring. In our article, we will talk about how to trim a staircase with a laminate.

We will also consider which board for finishing stairs is best suited and what nuances in its selection and installation will have to be taken into account.

The content of the article

Laminate steps

Properly finishing the stairs in the house is as important as laying the floor. Indeed, the facing of the steps of the stairs not only decorates them, but experiences considerable loads during operation.

And if you want staircase decoration In the house, the laminate was produced in accordance with all the rules, let's start with the choice of material.

So:

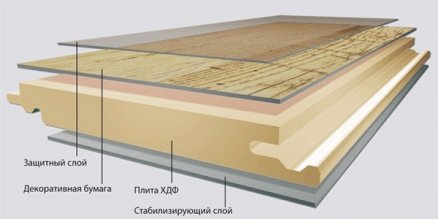

- A laminated board consists of several layers: high density fiberboard on a stabilizing substrate and a decorative paper layer coated with melamine or acrylate resin.

- Depending on the manufacturer, the composition of the panel may vary, have different configurations of the lock joints. Any laminated board belongs to its class.

The classification of this material used for the production of flooring is carried out according to the degree of resistance to abrasion, impact resistance, water resistance and some other indicators.

- In total there are six classes of laminate flooring: 21; 22; 23 and 31; 32; 33. Class numbers starting with a deuce are options for home use.

Starting from grade 31, a laminated board for commercial applications where higher loads are expected. Laminate flooring wooden stairs must be performed using this material of at least grade 31. - When purchasing material, it is necessary to keep in mind some nuances. Each step should have a solid board.

Facing treads, like the steps themselves, is not done in pieces. Therefore, the width of the laminate must be calculated correctly. - Often the steps of the stairs have different widths, so you need to navigate the widest, and then, simply calculate the number of steps. The resulting number of boards will be needed only for facing treads.

- Then, multiply the riser height by the number of steps. If the stairs are marching, then there are also landings.

Their area also needs to be taken into account, adding it to the estimated amount of material required for facing staircases.

- Before you finish the laminate stairs, under each step you need to lay a polyethylene, or even better, cork substrate. It will provide good cushioning of the coating, as well as sound insulation when walking on stairs.

- In that case, the stairs are finished with a laminate with their own hands, and the stairs have a complex configuration, it is necessary to make cardboard templates, according to which cut the cladding and substrate elements. So you will avoid mistakes when cutting the material, and, as a result, its cost overruns.

- To connect different levels of surfaces, there are special profiles. One of them is in the photo above.

The design of the profile allows you to beautifully decorate the joints of the elements of the staircase cladding. The profile will also contribute to the distribution of loads on the surface of the board and its uniform abrasion. - Finishing with laminate stairs, requires a certain set of tools. The most convenient for cutting a laminated board is a jigsaw.

For lack of a jigsaw, you can cut the panels with a hacksaw and a circular saw. But, if you need to cut, for example, a hole for a baluster, it is better to use the usual narrow file for metal.

- Staircase in the house with a laminate, not without the use of screws. Each element must be fixed on both sides.

This is enough, as there will be additional fixation with a corner or profile.

To ensure that the fasteners are not corroded in the future, it is best to use stainless steel options: copper, brass or zinc. Of course, the price of such fasteners is slightly higher, but then, for facing the stairs you will not have to pay twice.

Facing steps with a board

Any staircase, not only wooden, but also metal or concrete (seeHow is a concrete staircase finished with wood) may be lined with wood. Often, for this purpose, use a cladding board from an array of hardwood: oak, larch, beech, mahogany or ebony.

- Nobody argues - it is very beautiful. Such staircase cladding elements are usually custom-made and fit perfectly together.

But such a facing is expensive, plus the services of a specialist who will have to be invited for installation.

Terrace composite board

Therefore, there should always be an alternative. We have already talked about the laminated board.

And another type of board, in which not only wood, but also polymers, is a composite terrace board, or, as it is otherwise called, decking.

So:

- The presence of polymers in the composition of the board gives it the highest strength and resistance to moisture. The decking board was originally created for the installation of terraces and is the best suited for facing stairs. Especially when you consider that it has an anti-slip surface.

- Moreover, the staircase can be not only in the house, but also on the porch. And the site in front of the house can also be laid out by decking.

By the way, the terraces are also lined with platforms before going down to the pool (seePool decoration: how to do it) How to do this, watch the video, and the instructions found on the Internet will help you master this type of work.

- As with the laminate, the width of the board should correspond to the width of the step. Decking is cut like any other board.

But it is more convenient to use it than other types, because the edges of the composite board do not require additional processing. The set for decking sells end decorative caps. - Working with a composite board when performing the facing of steps is somewhat different from how, for example, the stairs are finished with parquet. There are special ventilation holes in the cavity of the board. Decking is set with slots down.

It is very convenient to mount such a board to the metal frames of bolt and spiral staircases, using kleimers and self-tapping screws. - To edge the front of the tread, in the same way as in the case of a laminate, use a profile or aluminum corner. When fastening, before screwing in the screw, you must first drill a hole, since the board has a very dense structure - it will be easier to screw in a screw.

Finishing stairs with a composite board, goes well with other materials. For example, if there is a board on the tread, then the riser can be faced with mosaic tiles, clinker, stone, or porcelain.

Thus, your staircase will also acquire an original look.

Parquet steps

Unlike previous types of cladding, parquet board is more vulnerable to moisture and requires preliminary treatment with special impregnation. The width of the floorboard does not exceed twenty centimeters, which does not correspond to the width of the steps.

- But, on that he and a parquet to collect from small elements.Parquet board is larger than the whole parquet strip, which used to be the only element used to create such floor coverings.

Parquet plank of solid wood, was, and remains today, the most expensive type of flooring.

- Creating a parquet board not only made it possible to reduce the cost of parquet flooring, but also allowed it to be used in other types of finishes. And this is not only the decoration of stairs - today parquet is used in the decoration of walls, and even ceilings!

- To make a board cheaper, its multilayer structure allowed. The lower part of the board is made of cheap varieties of wood, which on top is covered with veneer of valuable varieties of wood.

The board has grooves on four sides, allowing it to be fixed with adjacent cladding elements. - When laying flooring made using parquet boards, preference is given to castle joints. When the stairs are finished with parquet, it is more convenient to use the adhesive installation method.

To ensure the isolation of the stairs from the booming noise that occurs when walking, it is best to use the cork substrate, which we wrote about above. - Both the substrate and the board are fixed with glue. First, the riser part is glued, and then the tread facing.

Otherwise, the work of facing the steps with a parquet board is not much different from that where other types of wood coatings are used. - An additional fastening to the cladding elements will be ensured by a profile, which, as in other cases, is used to decorate joints and reinforce the edges of steps experiencing the highest loads.

Here, in fact, the whole review on the decoration of the stairs with a board. All types of coatings that we talked about do not present any particular complexity in the production of works.

They may well be carried out independently, without the involvement of specialists. The main thing is to strictly observe the technology, and your staircase will serve you for a long time without causing any hassle.

Can a fiberboard material be used to finish a concrete staircase?