Finishing building facades with modern materials and options for combining them

There are certain types of natural materials that are used to decorate buildings, as they say, from time immemorial. These include ceramic tiles and clay bricks, various types of wood and stone.

But life does not stand still, more modern materials for decorating facades appear, allowing at the same time not only to veneer, but also to warm the house. Moreover, to do this fairly quickly, which reduces labor and energy costs.

And this, in turn, reduces the cost per square meter of housing.

The content of the article

Front panels: types and advantages

As a rule, facade panels are elements of ventilated facade systems. This system consists of a frame, insulation and decor.

Its essence lies in the fact that during installation, a gap is left between the wall of the building and the insulation, which will prevent condensation from accumulating there, and create a kind of heat shield.

So:

- The production of materials for the decoration of facades has gained considerable momentum in recent years, because the demand for these products is growing steadily. And the assortment is such that it is very difficult to make a choice: here are wood options, and metal-plastic, and multilayer, and various imitations.

- Some facade materialsand successfully used in interior interiors. Each of them has its own design, dimensions, installation method, but there is one factor that unites them - this is an elegant and solid appearance of a faced facade that does not require updating for many years.

Coated Metal Panels

This type of panel is made of galvanized metal sheets with a thickness of 0.5 or 0.7 mm, which are coated with a polymer coating.

So:

- Such a facing will not only be a reliable coating of any facade, but will also help to create a memorable design. After all, the polymer layer on the panel can have any relief and a bright, juicy color, as in the photo below.

- The variety of shapes and reliefs allows you to combine panels as you like, making it possible to clad a facade of any configuration. The width of the joints between them can also vary, allowing you to adjust the cladding around the perimeter of the facade.

Upon purchase, you will be given installation instructions in the store. - Metal panels such as PF, can have a hidden or visible mount. Manufacturers also make them according to individual orders, if non-standard forms are required in the form of trapezoid, semicircles or corner elements.

These panels can vary in appearance, and be corrugated or flat, have a rib or wood texture. Naturally, the price is the higher, the more complicated their configuration and decor.

When installing metal panels, the same components are used as with facade decoration siding. To learn more about the installation process of the frame and panels, watch the video, look for articles on this topic.

Fiber cement textured panels

The undoubted advantage of this kind of panels is the fact that they qualitatively imitate other materials for the decoration of facades: brick and masonry, decorative plaster, tile cladding.

So:

- They are made of cement, with the addition of synthetic fiber and dissolved pulp. Most often, the top layer of fiber cement panels is ceramic.

That is why they have high strength, do not change color during operation, are not afraid of fire, and are resistant to any external influences. - Scopes of these panels extend not only to facade decoration and socles of houses, but also on the interior decor of residential premises and office buildings.

- There are options for fibropanels with coatings of polyurethane, acrylic, dusting marble and granite chips. The manufacturing process looks something like this.

The dry ingredients are first compiled and balanced, and the solution is kneaded.

The resulting plastic mass is sent to the molding extruder, where the products are given the necessary shape. Then they are burned and treated with protective primers and a decorative coating is applied.

The result is panels of remarkable quality and appearance.

Facade wood panels

Wood also did not stay away from the production of facade panels. They are based on wood fibers pressed at high pressure and temperature.

The binder, in this case, are polymeric compounds.

So:

- The protective and decorating layer is a painted surface, wood veneer, or polyurethane spraying. Therefore, there are many variations in the appearance of wood panels, which allows you to beautifully combine them in one facade.

- Importantly, wood boards are lightweight. And the decoration of the facade with light materials significantly reduces the load on the walls and foundation of the building.

This type of panels is easier to process than others: drilling, sawing. - Between themselves they are connected by a tongue-and-groove method, easily mounted on glue, or crate. This is perhaps the easiest way to finish the facade of a wooden house.

In this case, during installation, nails can also be used. For self-tapping screws and nails, the panels have a special edge with perforation. - The service life of wood panels is lower than the previous two options (up to 15 years), but they are much cheaper. This has its own plus - the facade will be easy to update.

Although, there are waterproof options, which include molten paraffin or ceresin. - They make the wood board not only more resistant to moisture, but also significantly increase its strength. Accordingly with the quality, the cost of the product rises, and can vary from 450 to 3500 rubles per panel, depending on the manufacturer.

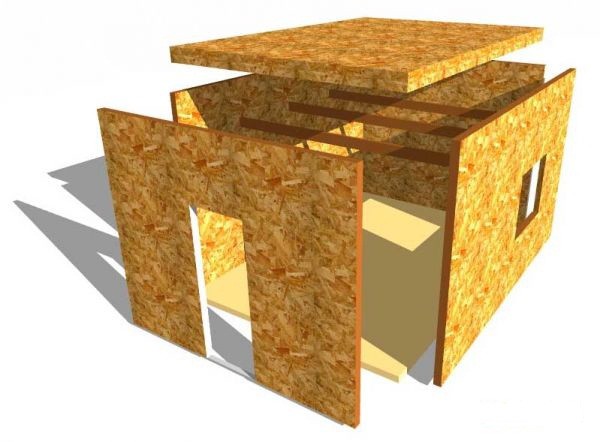

- There is also a simpler version of the facing material, with which you can make a chic facade. Not so long ago, the so-called OSB boards appeared on the domestic construction markets.

This is an imported material, outwardly similar to the familiar chipboard.

- The OSB structure of the plates is similar to that described above, so they are not afraid of moisture. This material comes from the factory in large sheets, and you can cut them yourself, and at your discretion.

As, however, and decorate.

And look: what a beautiful facade, in the style of fachwerk, can be obtained using wood panels and panels. In our example, we used both OSB boards and decorative wood panels, which we just talked about.

What are thermal panels

If the device of ventilated facades still needs to take care of the insulation, then the use of thermal panels immediately "kills two birds with one stone." They themselves are a heat-insulating material, they only have a decorative surface. Therefore, having acquired thermal panels, you do not need to buy materials for decorating the facade.

So:

- The technology of their manufacture includes several stages. The main raw material is polystyrene or polyurethane, which foams and granules are dried. In special block forms, they first lay the material that will make up the decorative layer, for example: clinker or stone tiles.

- At the next stage, granular insulation is loaded into the molds and heated with hot steam. At the same time, the granules melt, are pressed with tiles, and the finished panels are cooled, after which they should settle for a day.

It turns out here are such compact, and remarkably matching products.

- These unusually light materials for the decoration of facades help to solve several problems for stasis. Insulate and clad a small house with any material is not a problem.

But the smaller the details of the cladding, the more effort and time will be required for the production of exterior finishing work.

What to say about high-rise buildings, which also need to be insulated and decorated? Here thermal panels are simply irreplaceable.

In addition to the fact that they will create a high-quality exterior of the building, their application will significantly save the construction budget. Moreover, their decorative layer can be natural, and not just imitated.