Mosaic plaster: types of material

Mosaic decorative plaster looks great on the plane, however, its laying is not so simple. But still quite do-it-yourself. Then the finish price will not be high. It is about this coverage that we will talk today. You will also have the opportunity to watch the video in this article and the photo by which you can choose the most acceptable dye.

The content of the article

Foundation requirements

Mosaic facade plaster is applied to different surfaces, but here it should be understood that there are certain requirements for the base plane. Mosaic plaster video will show you this in more detail.

So:

- Decorative plaster must be applied on a solid and dry base, without efflorescenceunstable chalk coatings, as well as greasy spots. If any, they should be eliminated.

- The prepared base on facades and other surfaces in contact with moisture should not be water repellentto avoid poor adhesion with primers and adhesive component of the stucco mixture.

- Wall elements made of metal must be coated with special primers to provide protection against rust. Wood surfaces should be pre-treated with linseed oil and wait until it dries completely.

- Joints between building boards and other structural parts must be securely connected to each other to prevent mechanical deformation on both kink and tear.

The use of mosaic plaster mixture on the following types of coatings is allowed:

- Cement bonded particleboards;

- Gypsum plasters;

- Facade fillers;

- Interior putties;

- Thermal insulation systems with expanded polystyrene;

- Concrete base;

- Cement-sand plaster compositions.

- Drywall.

Caution: Mosaic plaster mix is not recommended for use on horizontal surfaces subject to prolonged exposure to moisture.

If necessary, in order to prevent the suction of water from the inside, it is necessary to provide waterproofing protection of the base elements. All preparatory and finishing work should be carried out at a base temperature above + 8 ° C.

Technology of work

Facade work should be carefully planned, given the upcoming weather conditions. This applies to stone mosaic plaster and to the rest of the milestones.

Attention: It should be remembered that it is necessary to apply the mosaic plaster mixture from one corner of the wall to the other, preventing the drying of the boundaries of the joined sections during application.

It is necessary to ensure the following conditions are met during the work:

- The presence of a sufficient number of competent workers and the determination of each of them the field of application of the composition and pace of work.

- Compliance with all recommendations on the organization of work, high-quality preparation of the base and temperature conditions. In cases where it is not possible to comply with the required environmental conditions, postpone work and wait for suitable conditions. When carrying out facade work, it is important to create a protective coating of polyethylene or a special mesh to protect the surface from exposure to the sun, wind, rain and snow.

- The controlled withdrawal of water from the horizontal planes of the facade must be ensured by a competent drainage system.

- Before applying the next coat of preparatory or topcoat, make sure that the base to be treated is sufficiently strong and completely dry, and that the materials have passed the required stages of strengthening or polymerization, in accordance with the instructions for their use.

- For 3 days after processing, it is important to protect the decorative coating from moisture and to ensure a temperature regime above + 10 ° C. It should also be ensured that scaffolding does not touch the work surface, and the distance to the wall is about 50 cm.

- It is important to keep the surface of the scaffolding clean, because rain spray, combined with dirt on the scaffolding, can get on the wall and significantly affect the decorative qualities of the facade.

- You should not choose the dark colors of the decorative mixture for application on large sections of the wall, as there is a possibility of a slight whiteness after rain, sometimes quite noticeable.

When carrying out interior work, it is necessary to clearly plan the sequence of related and related procedures. All roughing and installation work, which may have a negative impact on the decorative qualities of the coating, should be completed in advance.

- All elements and structures that are joined to the treated area should be protected with paper tape or covered with polyethylene. When applying impregnation and soil in the vicinity of the area protected by the tape, you must try to prevent the preparation materials from falling on it because of the likelihood of adhesive tape sticking to its surface and its damage.

- To prevent contamination and damage to flooring in the area of the finishing work, the floors must be covered with protective materials.

- If the area of the walls to be trimmed is very large, and the labor resources are not enough, it is permissible to take a break in the finishing work until the next work shift with the definition of an even border using a masking tape along the vertical edge of one of the sides of the door slope, arch (see Decorating the arch with mosaics: how to do it yourself) or windows.

- The masking tape, after applying and smoothing the mixture, must be carefully removed until it is dry. On the next day, after the treated surface is completely dry, adhesive tape is glued to its border and docked at the same level as the treated area with a new one. It is important to carefully ensure that the conjugate structures are not dirty with finishing materials. If this happens, immediately clean the area with a clean, damp cloth or sponge.

- During the finishing work it is necessary to try to exclude the presence of strangers in the nearby area in order to exclude accidental damage to the fresh coating. In addition, warning announcements should be placed, as well as requiring the customer to take all necessary measures to maintain the work of the contractor.

Preparatory work

Applying mosaic plaster video you will show the preparation of the plane before work. Before applying the mixture to a pre-leveled base, it is necessary to treat the surface with preparatory materials.

Impregnation

First of all, with the painting technique, with the help of a roller and a brush, it is necessary to impregnate deep penetration with plenty. In this case, the decorative mosaic plaster will hold firmly on the plane of application.

Attention: This will strengthen and dedust the surface, equalize the degree of hygroscopicity of the base and improve adhesion to various materials.

In a situation where surface areas have different hygroscopicity on the same wall plane (for example, fresh putty and oil paint, drywall sheets and joints sealed with putty), the impregnation should be performed twice, with the gap necessary for the first layer to completely dry from 4 to 6 hours.

Primer

After treatment with impregnation, you should wait until the surface has completely dried, on average it takes from 4 to 6 hours. Next, a special primer with a fine quartz filler is applied to a dry surface.It is the filler that provides the roughness necessary to prevent the grains of sand from slipping off the decorative stucco mixture during application, and the occurrence of noticeable gaps when drying.

So:

- Thoroughly mix before applying the primer.so that the quartz filler, which may have settled on the bottom of the package during storage, is evenly distributed.

- To create a uniform tone for the stucco mixture, you should tint the soil in a gray tintusing a paste of black dye (colorant) for this, and then apply twice to the surface using a roller and brush, using techniques of painting technique.

- The tinting of the primer is carried out in accordance with the tone of the mosaic plaster mix as follows: for a plaster mixture of light tones, black color in the amount of 10 ml must be mixed with a primer weighing 15 kg, for medium - 15 ml, for dark - 20 ml.

- If you have to use several packages of material, you should use the same amount of dye.. Dosing is most convenient with a disposable syringe.

- The packaging with the dye should be shaken vigorously before use for about 2 minutesso that the mixture is evenly mixed. Adding a colorant to the primer, the mixture should be carefully mixed to achieve a uniform color. Within 30 minutes, the mixture should settle, and then the priming process can begin.

- Large areas should be treated with a small pile roller., and the junction of the corners and other mating surfaces - with a paint brush.

- In the process of applying a primer layer, it is necessary to achieve the creation of a uniform and uniform surface. This can only be achieved if a second, final coat is applied. To completely dry the first layer, at least 5 hours are required.

- After reprocessing, it is possible to start finishing with mosaic plaster the next day.to make sure that the chemical processes that occur with the primer are completely completed. For exterior decoration, materials should be applied to a completely dry base, well protected from rain, snow, wind and sun.

- During work, the air temperature should be from +8 to + 30 ° C. After completion of work, all instruments should be washed very well with water and tightly close the packaging with the remaining material.

Material properties

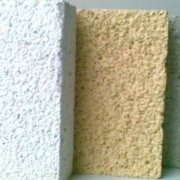

Facade mosaic plaster is available in retail chains in finished form, has a creamy consistency and is packaged in 25 kg containers.

- Before applying, to prevent the occurrence of discrepancies on the wall, it is recommended to put in a large container the amount of mixture that is required to finish one plane of the wall, and mix it thoroughly with a mixer.

- The plaster should be applied in a dense layer, moving from one corner to another, without interruptions, to exclude the formation of noticeable gaps and boundaries between the already dried and freshly processed area. The layer should be a half and a half grains of silica sand.

- The adhesive component in the plaster mixture before and immediately after use gives a whitish hue. After a couple of days, after the final drying, the whiteness disappears, and the plaster takes its final form.

Plastering technology

To get a high-quality, uniform coating and to avoid the appearance of traces from the used tool, it is recommended that in the initial period of drying, smooth the decorative surface with a metal trowel, using portable lighting or a spotlight and placing them at an acute angle with respect to the wall.

- When decorating, it is important to provide conditions that will prevent various precipitation from entering the freshly treated surface, and protect from exposure to the sun and wind.

- The most favorable temperature of the air and the base itself during the finishing work using decorative plaster is in the range from +10 to +30 ° С. This temperature regime must be observed until the coating is completely dry.

Attention: First of all, it is necessary to check the flatness of the plane. After all, the coating will completely repeat the surface contour.

Plaster drying

The drying process of mosaic plaster used indoors and for exterior decoration should occur naturally.

Caution: Do not use heat guns and fans to achieve faster drying of the coating.

- When decorating the facade You can not work in strong winds, as well as in direct sunlight. In addition, it is worth remembering that next to heating batteries there is also usually an elevated temperature, therefore, if this is possible, it is recommended to temporarily isolate or disconnect them for the duration of the work and until the plaster composition finally dries.

- Low temperature and high humidity significantly increase the amount of time required for the plaster mixture to dry, which can adversely affect the quality of the material due to irreversible processes occurring in the adhesive composition. This can lead to a loss of adhesive properties of the coating, its shedding and the appearance of discrepancies as a result of whiteness.

- The drying period "on touch" is usually from 8 to 12 hours. The period of time required for drying under favorable conditions to operational characteristics should be more than 48 hours.

Docking principles

Sometimes, for decorative purposes, when decorating facades, as well as indoors, the use of several colors on the same plane is required. To create clear and even borders, paper tape is the best option. With horizontal delimitation, you first need to apply the upper area, and only then the lower one.

So:

- Using a stylus pencil on a dried primed surface, slightly noticeable notches should be made, and between them, tightly, with a stretch, stick adhesive tape. Then you need to check the evenness of the line and apply the mosaic plaster mixture to the area, capturing the surface of the adhesive tape.

- At the final smoothing, the tape should be carefully removed and the edges trimmed. When the mixture on the top section is completely dry, on its bottom edge, not reaching 1 mm to the border line, you should glue a new strip of adhesive tape and begin processing the lower section.

- Avoid getting the mixture from the lower zone onto the masking tape in the upper zone and periodically remove any material that has fallen onto the tape. It is important that when smoothing the lower zone, the layers are equal in thickness, and there are no noticeable gaps in the boundary region.

- To create logos, the best option is to use pre-prepared stencils. A layer of the mixture on the stencil should be applied to a completely dry surface. If the logo is large enough and it takes a lot of time to cover it with the composition, you should clearly control the drying of the mixture in the treated areas in order to timely smooth the layer and remove the stencil from this area.

- If the decorative layer at the border of masking tape or stencil is dry, upon removal there is a high probability of obtaining a torn, rather unaesthetic edge, which is very difficult to restore.

Video application of mosaic plaster will help you deal with this issue in more detail and the instructions will not make mistakes during work.