Gypsum plaster and technique for working with it

Decorative plaster on a gypsum basis or starting, is widely used in the repair of buildings. She is increasingly preferred over cement-lime dry formulations. This is due to the characteristics of the finished solution, which provides gypsum, which is the basis for the production of the material.

Details about the composition of gypsum plaster, the technical characteristics of the mixture, as well as the technology for applying gypsum plaster, are described in the article.

The content of the article

Material Features

The basis of standard plaster is gypsum with the addition of it:

- Lightweight fillers, which reduces the consumption of the solution.

- High quality modifying additives to increase the adhesion of the mixture and the surface of the wall.

Gypsum plaster applied:

- When leveling surfaces in horizontal and vertical directions.

- To prepare walls or ceilings for applying a decorative coating.

Such a finishing material used for indoor and outdoor use:

- Not cracking.

- It goes well with other decorative coatings.

- It does no harm to the environment.

- Upon drying, the surface remains flat.

- It has the necessary plasticity, which allows the use of a solution for walling concrete and other materials.

The advantages of gypsum plaster are:

- High speed surface finish.

- Simplicity of a covering of surfaces. The mixture can be applied in a single layer, and to obtain a high-quality finish, only one tool is used and strict observance of the sequence of all operations.

- High elasticity compared to cementitious compounds.

- Affordable price.

- Outward appeal.

- The ability to give the surface all kinds of colors and textures.

- Protection of thermal insulation of the building from moisture.

- Frost resistance.

- Resistance to corrosion.

- A comfortable microclimate is created in the room.

Thanks to gypsum plaster, such characteristics are inherent as:

- Fire safety.

- Strength.

- Thermal stability.

- Excellent heat and sound insulation.

- Long term of operation. Material:

- almost does not shrink;

- does not form a “wrinkled” pattern on the surface.

- Suitability for decorative finishes.

- Lightness and good elasticity. Material is perfectly distributed on the trimmed surface.

Disadvantages of gypsum-based plaster:

- Short pot life of the finished solution, approximately 40 minutes.

- Low resistance to mechanical damage and moisture.

What types of gypsum plaster are

The composition of the finishing gypsum materials for indoor and outdoor works are of three categories:

- Fine-grained. In addition to the gypsum base, they also have ground sand. Because of this, cracks can form on the surface after drying, which requires the application of such a composition with a layer no thicker than 8 millimeters.

- Medium grained. This is the most popular and quite popular option. The presence of a medium-sized filler in it allows you to apply a coating thickness of up to 50 millimeters with this composition.

- Coarse grained. They are used when it is necessary to perform plastering of walls with gypsum plaster with a sufficiently thick layer. For example, gypsum plaster stucco in heavily broken door openings when replacing them.

Typically, gypsum plasters are taken for interior use (see Types of plasters for interior decoration: choose correctly) But manufacturers began to produce facade mixtures that are suitable for outdoor work.

It:

- Gypsum-polymer compositions. Such materials are used to level dense concrete, gypsum concrete surfaces, silicate brick walls (see Plastering brick walls according to all the rules), applying a thin layer of plaster on them.

These solutions can be used for facade work. The presence of polymer modifiers creates a greater coating strength and its frost resistance several times, from a conventional gypsum mortar.

Polymer additives make the structure of the plaster optimal for application to the surface, increase its adhesion to the base of the walls and elasticity.

Tip: When using polymer-gypsum mixtures, more time should be left to dry before applying the next coating layer.

- Gypsum-mineral plasters. They are used for finishing facades and other outdoor works. Mineral plasticizers in gypsum composition are additional binders, which increases the resistance of the material to external influences, makes it more plastic.

How to choose the right plaster

All gypsum plasters produced are divided into two main types:

- Compositions for outdoor use, for plastering:

- facades;

- basement (see Plaster plinth as a way to protect, strengthen and decorate);

- wall decorations in rooms with high humidity.

- Compositions for internal work carried out in rooms where low and medium humidity.

When doing DIY plaster-based plastering, you can not save on materials.

Tip: Cheap and poor quality mixes can cause repeated plastering of the surface. When choosing a type of plaster, you need to pay attention to what kind of work it is intended for.

Instructions for the use of gypsum plaster indicate that:

- Dry mixes should be dissolved only in clean containers and clean tools, with exact observance of the manufacturer's recommendations for choosing the ratio of dry mix to water.

- If it is necessary to paint the plaster with a different color, you need to make sure that the coloring material or paint mixes well with the gypsum mixture, otherwise the resulting composition can differ greatly in properties from those declared by the manufacturing companies, which will lead to unexpected results.

- When purchasing a solution in a ready-made form, it is not worth adding water or other solvents to it.

- To perform a high-quality coating, the plastering surface must be well dried, free of grease, any dirt, dust and traces of paint, this may interfere with high-quality adhesion of materials.

- Regardless of the work, indoors or outdoors, before buying gypsum-based plasters, you should carefully read the manufacturer's recommendations indicated on the label. Its cost is affected by:

- structure;

- quality;

- properties.

Tip: It will be gypsum plaster for aerated concrete, or for other material, acquiring the composition, you should focus on reviews about the manufacturers and choose reputable companies, not focusing on cost.

Most popular are:

- Perfect gypsum plaster for finishing heated rooms.

- Aegis will win gypsum plaster. It is used for leveling, sound and heat insulation of internal and external surfaces, in the construction of brick walls, expanded clay concrete, concrete ceilings.

Well-known manufacturers of gypsum plaster, such as:

- Plaster plaster "Knauf Rothband". The name of this company is associated with high quality products.Using traditional recipes, the German company produces a fairly wide range of mixes for performing internal and external plastering work. For the facade cladding, the gypsum mixture Rothband, made according to the classical recipe, is popular.

- Plaster "Volma" plaster. Packing the composition in the photo.

The products of this company are in second place in the production of plaster mixes. Manufacturers use a lightweight formulation, which makes it simple and easy to work with solutions, due to their "oiliness", the compositions are consumed quite economically. The plaster of this company is used for outdoor work and rooms with high humidity.

The long drying period and sometimes low moisture resistance can be considered a minus, which requires additional coating on plastered surfaces with special compounds and paints.

- Bergauf offers a wide range of plasters for interior and exterior use. It produces universal and premium mixes suitable for manual and machine work.

Additional advantages of plaster:

- elasticity;

- high drying speed;

- excellent ratio of quality and price;

- high adhesion.

These companies produce high-quality, environmentally friendly mixes for the decoration of facades and premises inside buildings, they can be plastered several times in a row.

How gypsum plaster is bred

Before you build gypsum plaster, you need to purchase:

- Dry mix.

- Capacity.

- Electric drill with nozzle or special mixer.

Then:

- The composition from the package is poured into a container with ordinary water: in this case, one kilogram of the mixture is taken per 0.5 liter of water.

- The mixture is well mixed with an electric drill until a uniform consistency is obtained.

- After about five minutes, the composition is mixed again.

Tip: The ready-made mortar should be used in 30 minutes, therefore, for work, the plaster should be diluted in portions.

- To reduce the operating time and material consumption, when finishing a large surface, you can use the machine coating method. At the same time, a high adhesion of the solution to the surfaces is ensured, it is evenly distributed along the plane and the probability of occurrence of cracks as the solution dries is eliminated.

In this case:

- a dry mixture is poured into the mixer of the unit;

- mixing it with water;

- the finished solution through a special hose enters the plaster feeding gun and is evenly applied to the work surface. To speed up drying, you need to provide good ventilation in the room.

Application technology

The technology of applying gypsum plaster to the surface offers:

- Prepare the surface for work. Gently clean it of dirt, grease, layers of the previous plaster, dust, and apply a primer with good adhesion properties.

- 30 kilograms of plaster are poured into warm water with a volume of 18 liters and mixed with a construction mixer.

- The stucco mortar hardens in thirty minutes, this requires a proportional decrease in the volume of the components of the composition, when one person is working.

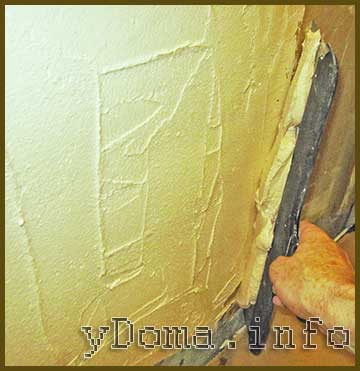

- The solution is applied to the surface with a spatula from the bottom up. The mixture should be leveled with a spatula after processing each square meter.

- From time to time it is necessary to tighten the wet plaster with the putty knife up, due to its falling down.

- About 20 minutes after applying the plaster, the surface is smoothed with a special plastic grater.

- Within 24 hours, the facade can once again be moistened with water, and then smooth it with a ironer. This will eliminate all kinds of defects that may be:

- smudges;

- badass;

- swimming off.

After applying gypsum plaster, the coating is completely smooth.When planning laying tiles on top of the plaster, secondary smoothing should not be done.

For decorative finishes, the plaster must be primed. The drying period of the surface depends on the humidity of the environment. When the thickness of the plaster is two centimeters, it will dry up to three weeks.

Details on the technical characteristics of gypsum plaster can be found in the video in this article. In any case, everyone chooses the plaster for finishing their home.