Knauf plaster and adhesive mixture Sevener 25kg: characteristics

Both among professionals and among beginner finishers, Knauf stucco mixtures are especially popular due to their quality, ease of application and a large assortment that allows you to choose the right composition for any type of work. One of them, Sevener plaster, will be described in great detail in this article.

The content of the article

Material Description

The mixture of stucco-adhesive Knauf Sevener is made on the basis of cement (see Cement or gypsum plaster: which is better to choose) It also includes fractional sand, special fibers and modifying additives, giving it high ductility, water-repellent properties, crack resistance and other positive qualities.

Advantages of the Sevener mixture

Like all other Knauf plaster mixes, this material is of high quality. And special properties are given to it by the components included in its composition, mixed in optimal proportions.

So:

- Special fibers in conjunction with polymers and water-repellent additives give this product resistance to cracking and the ability to repel water, which protects the base and insulation glued to it from the aggressive effects of moisture, prevents the appearance of dampness in the room;

- Sand of a certain fraction in combination with adhesive additives and binders give it maximum strength, good adhesion to the base, and ductility.

The Sevener Knauf stucco-adhesive mixture has an economical expense: depending on the type of work for which it is used, it is 3.5-7 kg / m2. That is, one bag of 25 kg may be enough to finish more than 7 sq.m. surface. Given that the price of packaging is just over 400 rubles, the costs of repair and construction work are low.

Specifications

| Indicators | Units rev. | Value |

| Compressive strength | MPa | 7,5 |

| Density after drying | kg / m3 | 1600 |

| Maximum fraction size | mm | 1,5 |

| Vapor permeability coefficient | mg / (m h Pa) | 0,1 |

| Frost resistance | cycle | 75 |

| Consumption | kg / m2 | 3,5-7 |

| Optimum application temperature | 0WITH | From +5 to +30 |

| Solution viability | hour | 2 |

Application

Due to its unique properties, the Knauf Sevener plaster-adhesive mixture can equally well be used for outdoor applications (see. How is plastering external walls), and for internal work.

Use cases

Already from the name it is clear that this building mixture is universal and can be used both as a plaster and as an adhesive.

It is intended for the following types of work:

- Repair of old plaster of building facades, including structural surfaces and coated with paints and varnishes, provided that they do not crumble and hold firmly to the base;

- Application of thin-layer intermediate plaster on smooth concrete and structured surfaces of mineral plaster, on coatings based on artificial resins and surfaces with a dispersion coating;

- The device of the coupling stucco bridge on the surfaces of porous or smooth concrete;

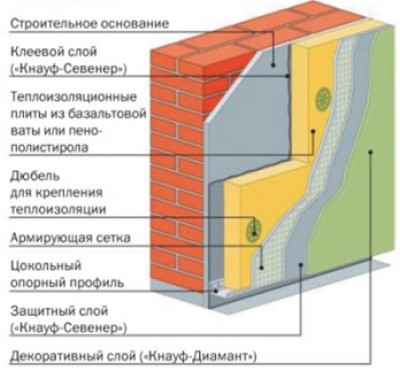

- Gluing to the base of thermal insulation boards made of mineral wool or expanded polystyrene when installing external thermal insulation systems;

- The device of the protective layer with fiberglass reinforcing mesh on top of insulation boards.

Note. The coating created with Severin mixes is an ideal base for subsequent finishing with materials such as the leveling mix stucco Goldband Knauf or decorative plaster Knauf Diamant.

Depending on the method of application, the flow rate of the dry mixture per square meter of surface also changes. For example, Severin Knauf plaster mix for gluing insulation to a flat surface is bred at the rate of 3.5 kg / m2and if masonry is lined with heat-insulating plates, it will already require 6 kg.

In the same way, for plastering even bases of material, less (5 kg) is required than for applying a layer on an old structural plaster (6-7 kg). The maximum flow rate is obtained when creating a reinforced protective layer on the surface of the insulation.

Application features

Regardless of the type of work for which the Knauf Sevener plaster mixture will be used, the foundation must be carefully prepared, having cleaned it of crumbling particles, dirt and dust.

Then the solution is prepared, instructions for its preparation are available on the package. Typically, 5 liters of water is required to knead 25 kg of dry mix.

For reference. The finished mixture can be applied both manually and mechanically, for which continuously working mortar-mixing pumps are used.

When applying with your own hands, the amount of prepared solution should be such that it can be fully developed in 2 hours. After the expiration of this time, it will begin to lose its properties.

Work should be done at positive air temperatures and freshly applied plaster should be protected from frost, as well as from direct sunlight and too quick drying.

Before continuing to work and applying plaster mixes leveling or decorative Knauf to the surface, it is necessary to wait for it to completely dry and coat with Knauf Izogrund primer.

Conclusion

We intentionally did not begin to describe in detail the process of working with this plaster: you will get acquainted with it by watching the video in this article. By choosing this material, you will be satisfied with the quality of the result.