How is plastering window slopes

The technology of plastering window slopes is not so complicated, everything can be done with your own hands and then the price will not be large. Today we will tell you how to plaster window slopes in different ways. You can also watch the video in this article and photos that will help you do everything quickly and efficiently.

The content of the article

Rules for plastering slopes

Plastering window slopes is done in several stages. All of them are important and worth nothing to miss. For work, purchase only high-quality material. This saves not worth it. Plastering the window slopes of the video will help in this matter. All work is done in the following order:

We select the tool

Here is a list of tools and accessories that will be needed for high-quality processing of slopes:

- Mortar for plaster

- Hammer (can be replaced with a hammer drill)

- SDS + to ½ ”adapter and drill chuck, this is needed to mix the mixture. It will help to obtain a uniform texture, to avoid the formation of excess lumps in the mixture

- Hammer

- Drills for a punch (the most running diameter is 6 mm, but you can take any others)

- Plastic dowels (suitable in size)

- Woodworking screws

- Screwdriver (preferably cross type)

- Bubble Level 2m

- Rules of aluminum of the right length

- Spatula shovel (best option 14 - 16)

- Ironing paddle, this is an important element, please note that without it at some stages something may not work

- Large capacity (you can take a bucket)

- Mixer nozzle

- Acrylic based primer "concrete contact" is possible

- Roller roller with a vessel or a large brush (you can take a wide paintbrush)

- Cotton gloves to protect the skin

- Stencil (template)

- Square

| Wall length | m | Bags needed: – or – |

| Wall height | m | |

| Average layer thickness | mm | |

| Type of plaster |

Prepare surface

The technology of plastering window slopes begins with the preparation of the base plane. This is important, since the quality of the work as a whole, as well as the durability of the structure, will depend on this, so it can take a lot of time to perform quality preparation, but these costs are justified

So:

- It is recommended to put the window sill before you start plastering. This will avoid the formation of cracks and gaps between the window and the windowsill, the formation of mechanical damage, and also strengthen the design.

- Plaster for slopes of windows can be from any building mix. The main thing when kneading, watch for its homogeneity. For kneading, it is better to use a construction mixer or drill with a nozzle.

Attention: It is best to protect the surface of the window sill from damage, because there is a high probability of a caustic solution getting on it, and, as a result, damage that can hardly be fixed, so you need to take care of the protection in advance: lay the surface with polyethylene, put sheets of paper, and so on .

- If traces of old plaster are present on the rim of the window opening, they must be removed (see How to remove old plaster from walls without problems), because the new layer should lie on a perfectly smooth surface that does not have irregularities

- The glass surface of the window is preferable to hang a protective cloth.If you produce plaster in one step, you can just stick it with pieces of adhesive tape. Do not forget to wrap pens and other items, if any, with paper or tape

- After the surface is cleaned, it is recommended to cut off the excess pieces of foam with a knife.

- To improve the contact of the solution with the surface, level the surface with a primer.

- Perform steam isolation procedure. On the inside, the foam needs to be fixed with a special film of the appropriate type, or a layer of frost-resistant liquid - sealant should be applied.

We recommend applying this solution to a perfectly dried surface, and immediately remove any residue from the surface.

Attention: Take into account the fact that without the use of sealant, the positive properties of the foam will be lost, condensation will accumulate on the window frames, drafts will appear, the work will have to be redone again, so I advise you not to miss this step

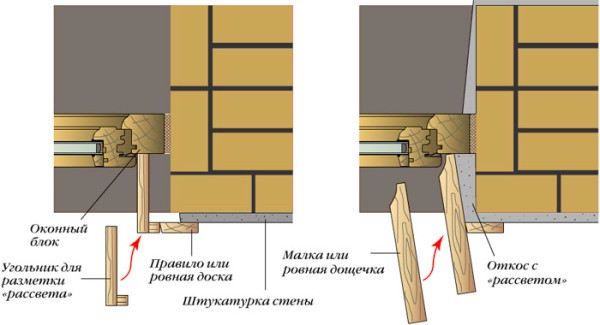

Attention: Be sure to do the little thing. This is the template with the help of which the most important thing is done - plastering the windows. Please note that the slopes of the windows are never straight, they always have a slight slope, which provides a window clearance.

- The standard malka is made of plywood and looks like a small piece of wood, a little longer than the slope (5 - 10 cm, but no more). On the one hand, the template has a slot, this is done so that during the work it can move along the slope, thereby further leveling its surface

- Because of this useful tool, after you remove the remnants of the unnecessary solution, the slope will be perfectly smooth. Be sure to make another cutout in which window loops will fit, this will save you from unnecessary work and simplify it.

- It is recommended to make the edges of the fry slightly rounded, this will ensure its integrity and prevent chipping of the ends.

- In professional work they use fry from various types of metal (most often aluminum), but for this they need to be ordered in specialized stores, and they cost an order of magnitude more expensive than manually made from wood. What to choose from these two options is a personal matter, but both options are good.

Slope plastering

Be prepared for the fact that it is impossible to make slopes in one quality step, so you will have to do the work in several.

So:

- First of all, you need to take care of the good contact of the substance with the treated surface, to ensure a better result, it is recommended to spray. The procedure consists in the fact that the solution, diluted to a liquid state, must be applied to the scapula and thrown onto the surface. This kind of surface preparation will provide better adhesion. This action needs to be done over the entire surface. This will give a very good result.

- The next step is the installation of rails, perform this action according to the instructions, which corresponds individually to each slope, but if necessary, you can proceed according to your own scheme. You can attach them to the solution, which does not give a guarantee over strength, or use standard fasteners, which will provide a sufficiently high strength. Thus, the quality of work will become even higher, because the rails seem to serve as regulators for mounting the slope.

- They must be securely fixed along a plumb line to avoid displacement and, as a result, unevenness of the resulting slope.

- The main slats are fixed, now it is worth making specialized fry, the purpose of which is to level the surface, as well as to adjust the edges of the slope

- To make this device is very simple. You will need an even piece of wood, which in length will slightly exceed the length of the slopes (by 10 - 15 cm). On the reverse side, a nail is hammered into the fry. The hat is best separated by wire cutters, otherwise they may scratch the surface.

In the manufacture of this design, follow the rules:

- Drive a nail up to a distance of 4-7 mm from the rail, but no more.

- You can protect the frames from mechanical damage with the help of nozzles made of insulation tape or other materials attached to the tip of the nail.

At this stage, the process of applying the solution to the slopes takes place. The layer can be primed using malki, namely, by smooth movements from the bottom up. Of course, excess solution is removed before it dries.

So:

- Wipe the surface also before the mixture dries. This is done using a specialized tool with translational movements (or movements from top to bottom).

- When the solution has dried, the slats are removed, and defects are corrected with a small amount of solution, which again is rubbed to a state of integrity with the surface.

- The next step is puttying (see How is puttying slopes) and surface painting. Putty should be done using a specialized spatula. The type of paint depends on the texture of the treated surface.

- Slope processing is carried out in several layers, professionals are advised to add a small amount of alabaster to the mortar mixture, which accelerates the drying process of the solution, but it is important not to overdo it - too much of this substance can lead to cracks, breaks and other defects.

Work with slopes in the presence of plastic windows

Plastering slopes of plastic windows is done a little differently. Plastering the slopes of the video windows will show this moment.

- When the main work is completed, but the mixture has not yet dried, a small furrow must be drawn between the slope and the window with a spatula, its thickness should not exceed 5 mm. After that, you need to fill it with a substance having hermetic properties.

- As a rule, windows made of plastic or PVC - especially if they are made of low-quality materials, tend to increase significantly in volume under the influence of high temperatures (especially in summer). Sometimes this can happen so noticeably that cracks and breaks can form at the junction of the slope and the frame. The positive properties of the sealant will help to avoid this.

The setting of protective angles is quite desirable. Let's find out what it is and what it is for:

- Folded along a metal tape with perforation is called an angular protective profile. As you can see, holes are located on the entire surface of the tape, this provides better adhesion to the surface being treated, since a solution leaks into these holes.

- These elements must be installed on both the external and internal sides of the slope, they serve as a protective surface and protect the slope from mechanical damage that can be obtained during use. But one of the main functions of this subject is to ensure a perfectly even angle, which is necessary for a quality slope.

- Choose dense, heavily bending constructions, avoid thin, squishy ones, they will not last long. Of course, the first ones are an order of magnitude more expensive, but they will save you from additional costs, as well as ensure the evenness of the angle, which is important. We recommend corners from Knauf, they are of very good quality.

- The corners are set on a slightly dried, wet solution.

- Consider in what order it is better to fix the corners. The first step is to separate several elements of the required length, it is also necessary to prepare a small amount of putty. Next, you need to place the solution as even as possible exactly from the inside of the corner, without affecting the rest of the surface. Place a corner and press firmly so that excess solution comes out of the holes.

- Upon completion of this procedure, it is necessary to check the correctness of the angle with the tool.If there are deviations from the desired result, the work should be adjusted again using the corners.

- Such a procedure should be done until the surface becomes perfectly smooth and even.

The technology of plastering window and door slopes is not fundamentally different. Plastering the slopes of the window videos will show you the most difficult areas of the work and you can do everything. Just use quality material and you will not know the problems in this matter.