Silicate Plaster

The market of finishing technologies is diverse, and silicate facade plaster occupies an honorable place here. Due to the safe chemical composition, environmental friendliness, operational and decorative properties, this versatile material is used in facade decoration and interior design.

The content of the article

Structure

Material silicate facade plaster refers to the polymer (dispersion) types of plasters. The binder is water glass, which is an aqueous alkaline solution of sodium silicate and potassium silicate. In the role of additives, colored pigments and mineral fillers are used: sand, marble chips or crushed fragments of other rocks.

The silicate mass for plaster is produced in sealed buckets in the form of a ready-made solution, which must be mixed before use to obtain a uniform consistency. In addition to colored plaster, manufacturers also produce white, which customers tint at will.

Important: work with silicate plaster requires caution. The solution contains alkali; therefore, the mixture must not be allowed to come into contact with the skin and eyes. Take care of gloves and goggles in advance.

Varieties of silicate plaster

With a similar composition, using this structural plaster, various coating textures are obtained: these are “bark beetle”, “fur coat” and “lamb”. The nature of the pattern depends on the size and shape of the mineral filler. For example, to obtain the texture of a lamb, you need a mixture with a filler with a grain size of 2-3 mm.

In the video in this article - a visual instruction for creating textures. After viewing it will be easy to do such work with your own hands.

Important: it is impossible to mix silicate plaster with other building mixes.

There is also a type of silicate-silicone plaster, which includes an emulsion of silicone resin. It differs from ordinary silicate in greater elasticity, sticks to the surface better, has increased strength, and is also resistant to mold and mildew.

Operational properties

- Silicate plaster - a decorative material for finishing. Previously, the walls are leveled using other materials. For example, a solution of a cement-sand mixture.

- The coating is vapor permeable: it passes into the external environment evaporation from wall materials and insulation. The walls breathe and do not damp.

- Silicate plaster is a waterproof material that prevents the penetration of moisture from the outside to the insulation and walls.

- When dried, the surface does not deform.

- The material is environmentally friendly, does not emit toxic fumes.

- The coating is resistant to the negative effects of atmospheric phenomena.

- Silicate plaster refers to a variety of structural coatings with the texture of “bark beetle”, “fur coat” or “lamb”.

- The solution is plastic and easy to apply.

- The material is resistant to stretching.

- The electrostaticity of silicate plaster is neutral. The coating does not attract dust, the facade remains clean.

- Compared to other decorative plasters, the price of this building mixture is more economical.

- The coating is off. It is used for finishing houses where combustible polystyrene foam is used for external insulation.

- A solution of silicate plaster is sold in packaging from 3-5 to 25-30 liters. You can select the required quantity.

Fields of application

When using a solution of silicate plaster, the properties of this material allow it to be used in the interior. But the most effective silicate plaster manifests itself in facade work. Often used for wall decoration from porous materials, such as aerated concrete. However, the mortar is suitable for bricks, concrete, and other structural materials. It forms a durable coating on the surface of the external insulation.

Silicate plaster has a weak ability to adhere - sticking to the base and creating a strong bond with it. Therefore, before starting plastering, a silicate primer should be applied to the wall surface from any material.

Important: a reinforcing mesh is required to apply the solution to mineral wool insulation. And if the external insulation is polystyrene foam, its surface is pre-treated with a silicate primer.

Weak spots

Silicate plaster has several disadvantages:

- To improve adhesion, silicate plaster requires preliminary treatment of the base with a special primer, which increases the cost of finishing.

- The solution quickly loses its plasticity. You need to work quickly, covering the surface of the wall in one go, otherwise it will then be difficult to hide the junction of the layers of plaster. It is difficult for beginners to cope with this task.

- The color scheme of finished tinted solutions is not wide enough. But this is easy to handle by buying an unpainted solution and choosing the right color pigment. In some cases, the coating is painted with facade silicate paint.

- Silicate facade plaster is prone to fading in the sun.

Interesting: when painting the facade in two colors, an unusual decorative technique is obtained. The first paint the wall is painted over the entire depth of the texture - this is the background. And the second color is applied only to the protruding areas of the coating, emphasizing the relief.

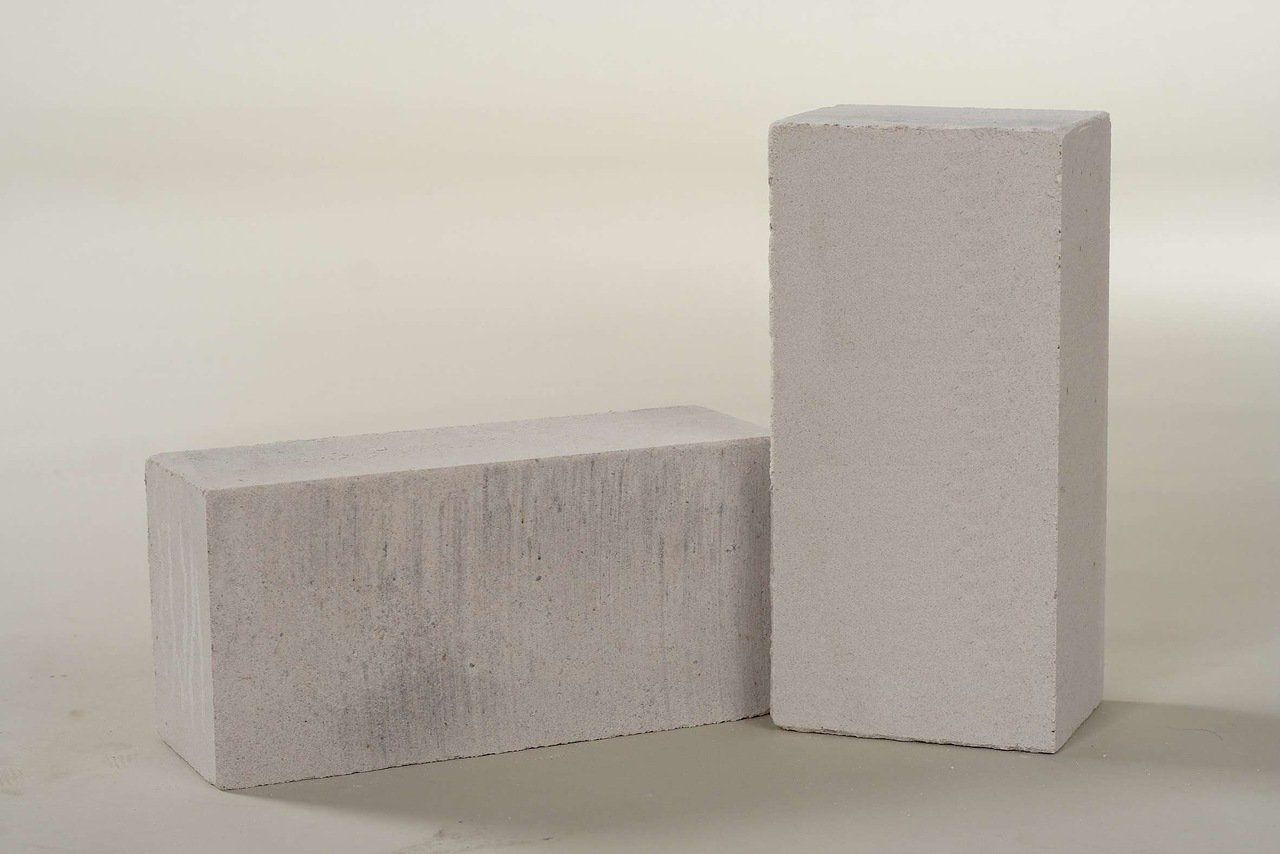

Silicate brick plaster

Speaking about the areas of application of silicate plaster, it is worth noting silicate brick. This is a popular building material: strong, durable, easy to use, but afraid of moisture. In addition, over time, it loses its original color, acquiring an earthy hue. Therefore, silicate brick plastering is not only a design issue. Water-resistant silicate plaster allows you to simultaneously protect the walls from atmospheric precipitation and give the house an aesthetic appearance.

Plastering silicate brick walls has features due to a smooth surface:

- Previously, the walls are thoroughly cleaned with a wire brush or a stream of water under pressure.

- Before applying a layer of silicate plaster, the wall is leveled, applying a calcareous-sand mixture to the fixed reinforcing mesh.

- After the preparation layer has dried, the surface is treated with a silicate primer.

- After the primer dries, a top coat of silicate plaster is applied. The layer thickness should not exceed the grain size of the filler, otherwise the desired texture will not work.

Sales leaders

Silicate plaster of many manufacturers is presented on the market. Leading positions are held by German companies WeberVetonit, Henkel and Kreisel. Each manufacturer has its own favorites:

- Weber.pas silicate-silicone plaster leads the Weber.pas company. In addition to the standard properties inherent in this type of mixes, weber.pas ExtraClean plaster is self-cleaning and UV resistant. It is tinted in 218 shades. The WeberVetonit product line is a luxury product line.

- Silk-silicone plasters Ceresit CT 174 and Ceresit CT 175 became leaders in sales at Henkel. The first was with a pebble grain texture (fraction size 1.5-2 mm), the second with a bark beetle structure (grain 2 mm) . They are made only in white as a basis for tinting.You can use color pigments according to the standards of the tinting systems ColorSystem, RAL, NCS. The flower standards from the collection “Nature's Palette” are popular: the album “Decorative Plaster”, 2017 edition. ”

- Kreisel produces two types of Kreisel 020 Silikatynk silicate plasters with DR (bark beetle) and BR (lamb) textures. The color palette of tinted solutions includes 259 colors. In places where it is possible the germination of moss and infection with spores of fungus or mold, the layer of plaster should be further treated with bactericidal agents.

Practical tips

Some practical tips for working with silicate plaster:

- When working with plaster, consider the weather: it is undesirable to work in hot weather and in rain.

- If the solution thickens, dilute the mixture with water.

- When calculating, consider the average consumption of the solution per 1 sq. m - 2-3 liters.

- Do not use rusty tools to work with silicate plaster - select plastic tools.

Silicate plaster is a popular material for finishing facades. It passes steam emanating from the walls and the external insulation, and at the same time reliably protects structures from atmospheric moisture, which is important for buildings made of silicate brick. And thanks to tinting and textures, this structural plaster is also in demand as a decorative finishing material.