Plaster corner

A plaster corner is a product that is used for decoration. With the help of the material, the external and internal corners are aligned and the composition is strengthened. To achieve a positive result, it is recommended that you familiarize yourself with the rules for choosing and using the product.

The content of the article

Product Types

Aligning the corners with plaster, as video tutorials show, is most easily done using corners. Such building material is used by professionals and amateurs. Products help to make a quality finish with your own hands. There are several types of products, in order to make the right choice, it is recommended that you familiarize yourself with the characteristics of each of them.

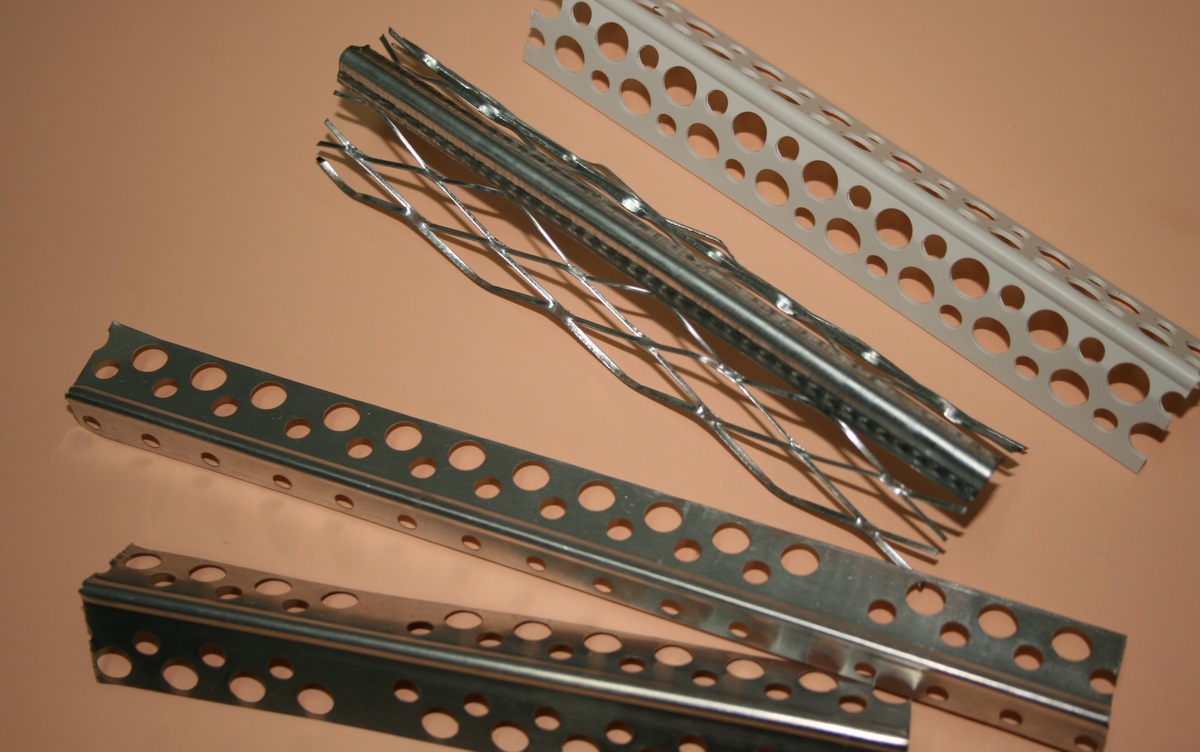

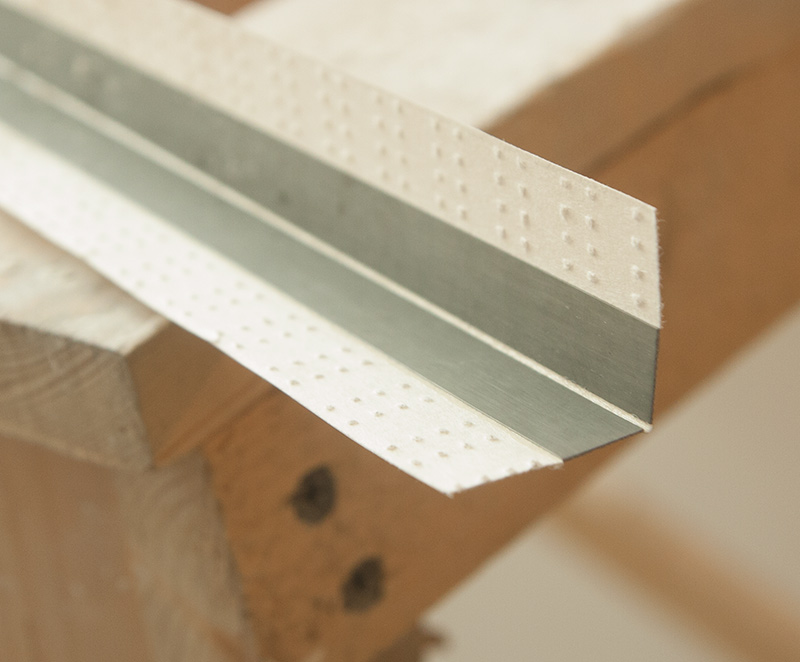

Metal corners

Metal corners are made of steel and aluminum. Each option has advantages and disadvantages.

Aluminum material has increased strength. Such a corner is slightly susceptible to corrosion and has a long operational period. The material weighs little, which simplifies the installation of the product. Light weight also does not create additional load on the surface, so the finish stays on the surface for a long time. Another advantage is the affordable price.

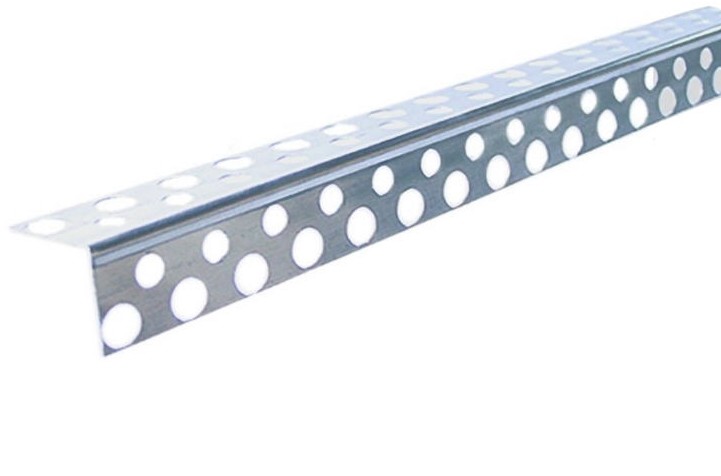

Steel products are susceptible to corrosion, therefore, during production, the material is galvanized. Zinc prevents rust, but can wear out due to damage. To prevent this, the corners are cut with scissors for metal. You can not be used for this purpose grinder. It is recommended to install the material with extreme care so as not to damage the galvanized layer.

The metal corner is used only for gypsum plaster or latex composition.

Plastic products

The angular equalizer of the plaster layer, which is made of plastic, is a high-quality and reliable product with a small weight. The material does not burden the structure because it is light in weight. The product is easy to use, has moisture resistance and resistance to alkalis, but is not strong enough in comparison with a metal product.

Types of designs

The plaster corner is divided into several types.

Right angles

They are a band bent in half with an angle of faces of 900 made of plastic or metal. Wall thicknesses up to 0.5 mm for a metal product and 1-1.5 mm for a plastic product. On the faces, as a rule, holes of different configurations are made. This lightens the weight of the product, reduces cost and improves adhesion to the material.

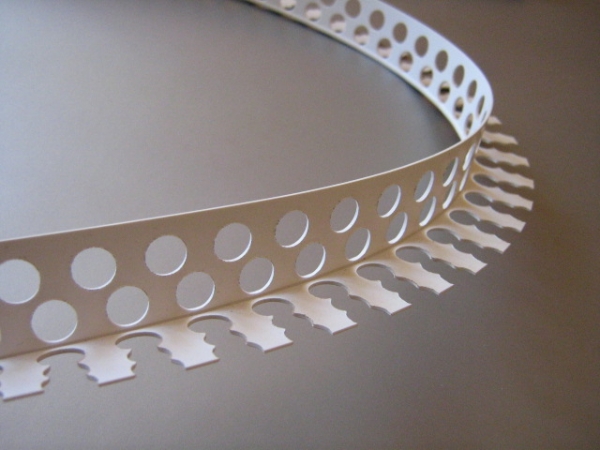

Arched products

For the manufacture of such corners use only plastic. Products use the design of curved external and internal corners. For ease of fixation, on the one hand, the product is a strip, and on the other hand, the corner is divided into segments.

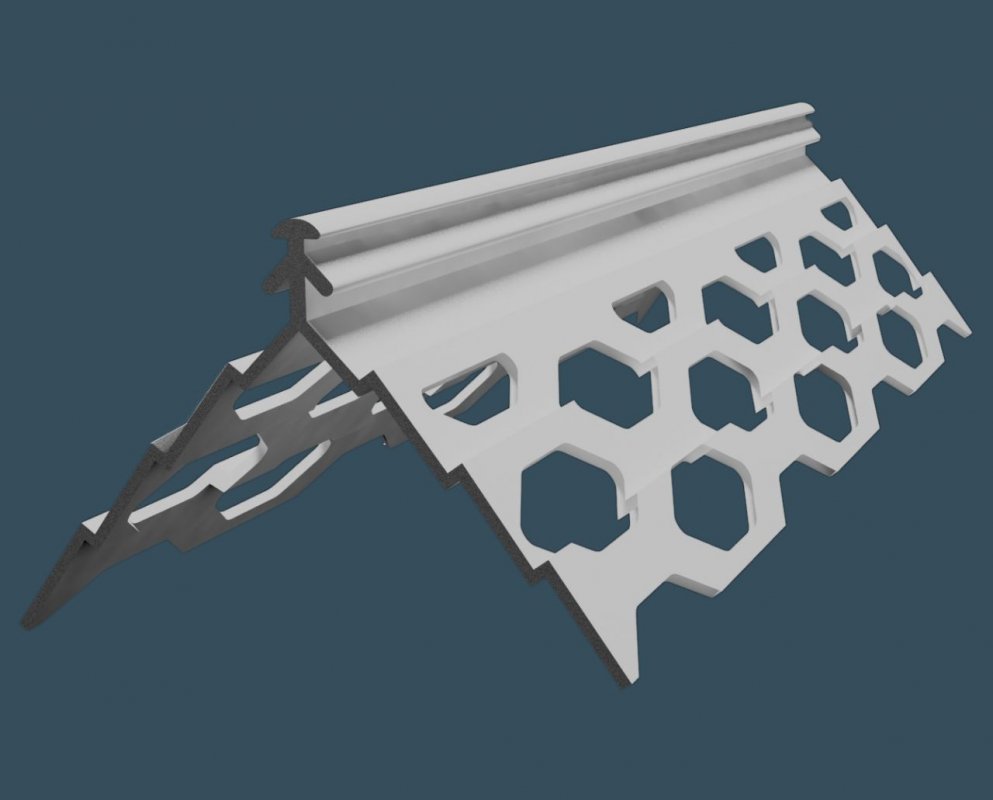

Universal product

The product is made from plastic with a mesh design, due to which they form non-standard angles. This type of product also includes non-woven and corner forming metallized tape.

Non-woven tape is a paper strip whose width is 5 cm with microperforation. Recesses are located along the length that allow bending.

A metallized tape is a perforated strip of paper, the width of which is 5 cm, metal strips, 1 cm long each, are located on both sides of the product.

Both products are intended, as the video instruction shows, to align the corners with plaster. Tapes are analogues of corners made of plastic and metal. Such products are suitable for corners of any configuration.

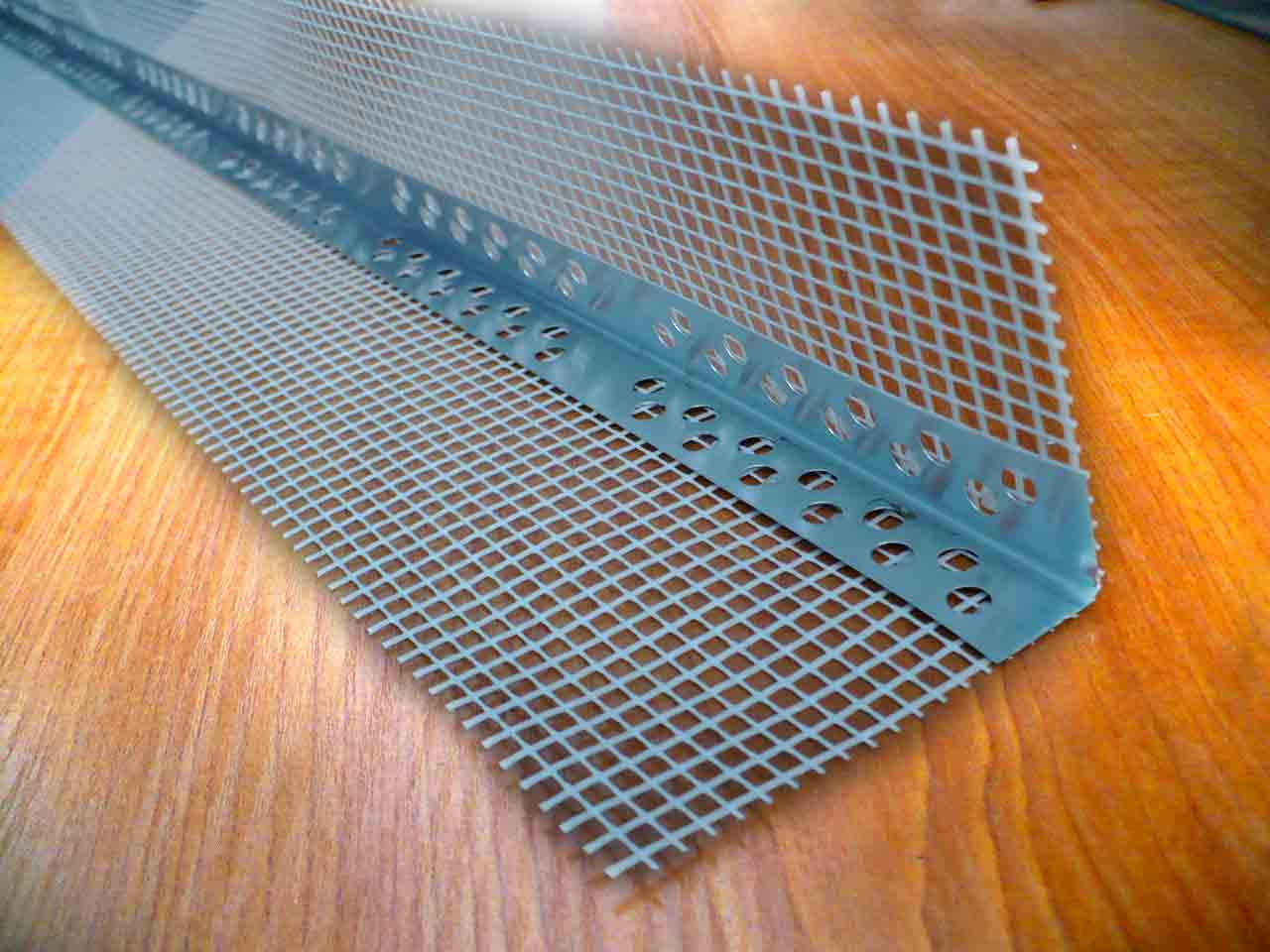

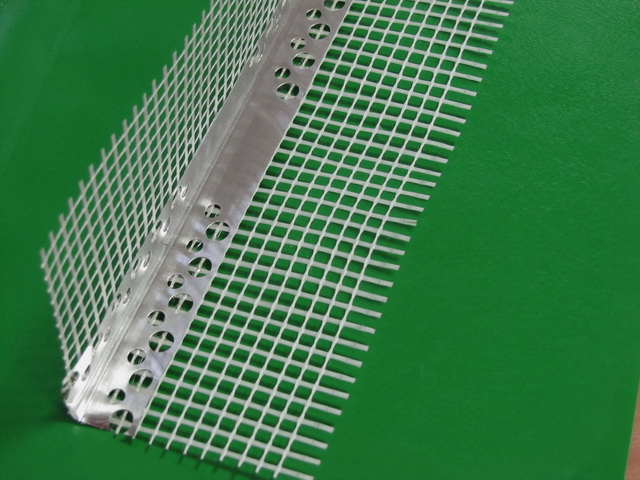

Mesh Products

It is a corner, on the sides of which a reinforcing mesh is attached, as in the photo below. The product is used if the finish is done by wet plastering the surface or if the material is applied in a thick layer. The width of the grid is 2-4 cm. For the manufacture of a corner, plastic or metal is used.

Combined Corners

Such products are corners with a reinforcing mesh, when the corner itself is made of metal, and the mesh is made of plastic. The product allows you to properly design the joints of the building base and clearly delineates the inner corner.

Material fixing rules

To secure the corner, it is recommended that you familiarize yourself with the installation rules of the product.

Preparing the corner for decoration

Before installing the corner for plaster, the construction base is prepared:

- The product is fixed only on a solid surface, therefore, before finishing, it is recommended to remove staggering elements that crumble during plastering.

- The surface is freed from the old coating.

- The building base is dusted off and treated with a primer in two layers with a break for each to dry.

- If the surface has severe curvatures and numerous defects, then cracks and depressions are filled with a stucco mortar and the corners and walls are leveled with the same tool.

- The product is set along the guides, which are fixed in level.

Product mount

The leveling plaster corner is fixed as follows:

- With a knife or scissors for metal cut the product to the desired size. Do not use a grinder, otherwise in the place where the cut was, the product will be subject to corrosion.

- A solution is applied to the building base. The tool is leveled with an angular spatula around the entire perimeter of the corner. The layer is made so that after mounting the corners of the product are on the same level with the guides.

- Without waiting for the material to solidify, a corner is applied to the solution and pressed so that the composition appears from the holes. With a spatula, such a product is leveled on the surface of the corner. If a product with a mesh is used for plastering, tones are also pressed into the material and the tool is spread with a spatula.

- Level and rule check the correctness of the finish. If defects are found, they are eliminated.

If plastering is performed with a thin layer, then the corners are fixed in another way. Product Installation Instructions:

- the corner is put to the surface;

- with the help of a drill, holes are made on a building base into which plastic dowels are inserted;

- self-tapping screws with washers are inserted into the dowels;

- fasteners are treated with an anti-corrosion solution to prevent rust.

Scrubbing and leveling

After the solution has solidified, to which the corners have been fixed, proceed to the next stage of finishing:

- the plaster is applied to the surface and to the corners and leveled with a spatula;

- the solution layer is made so that the corner is completely closed;

- after the agent has dried, the surface is cleaned with a special grater - first on one side of the corner, and then on the other;

- carefully drive with a grater in a circular motion so that no chips appear on the material;

- the inside corner is rubbed with a coarse grater.

The video in this article demonstrates how to properly mount corners.

Plaster corners are products that improve the quality of finish and facilitate the application of decorative material at the joints of surfaces. For these reasons, fans should use this material for self-repair.