Do-it-yourself facade plaster

Do-it-yourself facade plastering reduces costs by 3-4 times. A simple and clear instruction will help in this: read on, watch the video for this article and repeat all the steps.

The content of the article

How to make facade plaster with your own hands?

Do-it-yourself facade plastering is a budget way to give the building a finished look. To prepare such a solution is not as difficult as it might seem. As an astringent we use cement, gypsum or lime.

Depending on the situation, we use 3 options for such plaster:

- cement-sand;

- combined;

- lime-sand.

Let's consider each of them in detail.

1. Cement-sand plaster

We use Portland cement M500. The composition of the solution is 1: 4. We take 1 part of cement, 4 parts of sand. Add a plasticizer, such as liquid soap.

Gradually pour water and mix the solution thoroughly until a gray plastic mass is obtained.

We select the consistency so that it is convenient to work with the solution. Too thick a composition is difficult to stretch, and a liquid - drains from the tool and the wall.

2. Combined plaster

The composition of the solution: 1 part Portland cement M500; 0.5 parts slaked lime; 5 parts of sand. Such plaster better protects against moisture. It’s convenient to work with her. The composition is universal and will help out in any situation.

3. Lime and sand plaster

A budget option. The composition of the solution: 1 part lime, 4 parts sand. The main advantages are ductility and low weight.

The disadvantage is that the finish is not so strong and durable. Such a composition is better to repair the facade, and not plaster from scratch.

How to plaster a facade with your own hands

The process is responsible, but everyone can cope with it. It’s more convenient to work together. The steps of plaster are as follows:

- surface preparation and marking, installation of beacons;

- solution preparation and tool preparation;

- spray

- main layer;

- primer;

- finish layer;

- grouting and painting.

1. Preparation and marking of the surface, installation of beacons

- We clean the surface of dirt, dust and the remnants of the old finish. We use metal brushes.

Solvents will cope with greasy spots. And large pieces of old plaster are removed with a puncher with a special nozzle.

- In the brick walls we do the alignment - we clean and deepen the solution in the seams between the bricks. This improves adhesion to the plaster.

- We ground the walls with a special composition. The primer is applied with a paint roller. To eliminate missing areas, each passage overlaps the previous one by 50 mm. We wait 3-4 hours and primed the walls again.

- The next day we fix the plaster grid and do the markup.

How to set up lighthouses (photo No. 2):

- We determine the verticality of the wall using a plumb line. We plan in advance for ourselves where more solution is needed.

- We cut off a piece of the desired length from the plaster beacon (along the height of the wall).

The thicker the lighthouse, the more durable it is more convenient to work with it. But the thicker the layer of plaster.

- We retreat 200-300 mm from the corner of the wall. And vertically roll the solution with five fingers. We select the consistency so that the mixture does not fall down. The distance between the nickels is 50 cm.

Before this, we process the wall with spray water. So the solution sticks better.

- We attach the beacon, slightly push it into the solution. We use the rule with the level and set the beacon vertically. Remove excess solution with a spatula.

We use a rule with a minimum length of 1.5 m. The longer the rule, the more accurate the result.

- We wait 1 hour until the solution sets and gently fill with a solution of emptiness under the beacon.

We repeat the same thing on the other side of the wall. Further, at three points along the height of the wall, we pull a line between the extreme lighthouses and set intermediate guides.

We accept the installation step 200 mm shorter than the length of the rule.

2. Solution preparation and tool preparation

Kneading is calculated so that the solution is enough for 1 hour of work. For cooking, we use a plastic bucket with a capacity of 25 liters. We mix the solution with a drill with a special nozzle - a construction mixer.

For plaster we need the following tools:

- Master OK;

- putty knife;

- metal trowel;

- the rule

- grater

- spray bottle with water.

3. Spray

The solution for this stage resembles liquid sour cream in consistency. We pick it up in the bucket and throw it on the wall. It is important to correctly calculate the force: the solution should stick, and not bounce off the wall.

Pre-wet the wall with spray water.

We give the solution to dry for an hour and proceed to the application of the main layer.

4. The main layer

- We sketch the main layer between the beacons.

- Pull the solution along the guides from the bottom up. For this rule, we make reciprocating movements with a short amplitude in the horizontal direction. In this case, lightly press the beacons. And we move the excess solution from the bottom up, filling the voids along the way.

The thickness of the plaster is from 10 to 50 mm. For differences over 30 mm, we recommend applying the solution in 2 layers.

- When the plaster dries, carefully remove the guides. And the formed cavities are plastered.

- After the plaster of the straight sections has dried, go to the corners. We install corner plaster beacons using straight sections of the wall as a plane. Spray the solution and draw the corners.

Corner beacons are not removable. They protect the corners of the building from mechanical damage.

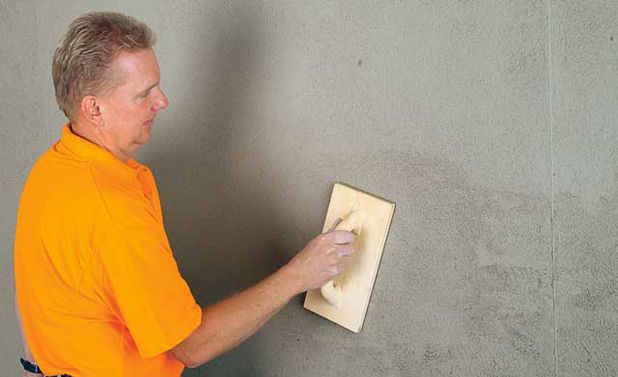

5. Grout

When the plaster dries, wipe it with a wooden or foam grater.

We do this in a circular motion in a spiral. So we remove the excess solution, fill the pits and smooth the surface.

When working with finished mixtures, the application technology may vary slightly. Follow manufacturer's recommendations clearly.

Detailed application of facade plaster is shown in the video below.

6. Primer

After the main layer has dried, the walls are primed again. This makes the plaster monolithic and prevents its shedding.

Often this stage is skipped, as a result, the finishes are peeled off after a few years.

We recommend using a deep penetration primer. This composition dries in 24 hours and provides excellent adhesion to the base coat.

6. Finish coat and painting

The final layer is preferably applied to the finished finishing plaster for outdoor use. It is sold in a hardware store and is inexpensive.

We apply the composition with a trowel and a spatula, a layer of 2-3 mm. So the surface is finally leveled and prepared for painting.

After the solution dries, apply the paint for the facade with a paint roller.

It is advisable to paint the entire wall at a time, without a break. Otherwise, in the light, different areas will differ from each other.

In the video, the application of facade plaster is shown in all details:

Beacon removal and grouting:

To summarize

The above method reduces the cost of plaster 3-4 times, but requires more time. How to plaster a facade: do it yourself or hire a craftsman, everyone decides for himself.

If you decide to plaster yourself:

- Pay particular attention to surface preparation and primer.Often these steps are overlooked or disrupted by technology. The price of such an attitude is wasted time and resources.

- Do not take long breaks during operation: the wall is plastered 1 time.

- When working at heights, follow safety instructions. Be sure to use protective equipment and a working tool.